Electric Manual Paper Waste Cleaner Waste Removal Machine Corrugated Carton Box Paper Waste Stripper

Strip all kinds of general cardboard, plastic sheet and leather products after die-cutting. It has compact structure, exquisite production, high pressure, high precision, convenient use, and reliable operation, which reduces the labor costs.

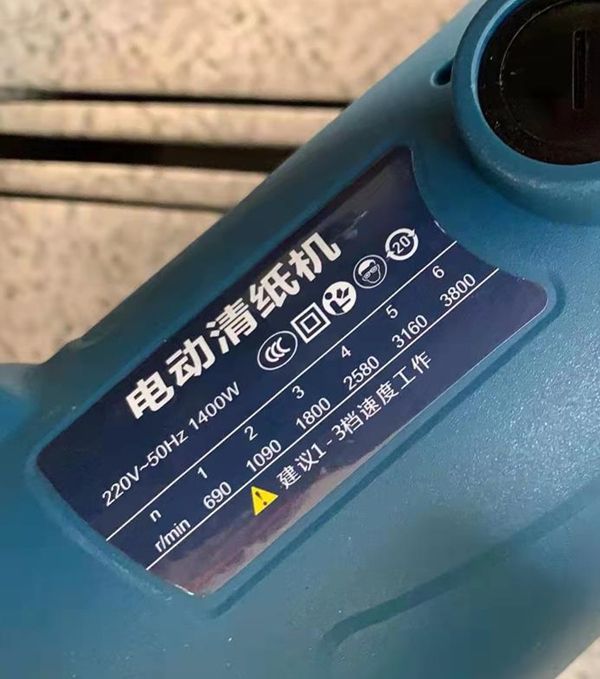

Technical Information

|

Item Number |

HS-D10S |

|

Type |

Electrical stripper |

|

Color |

BLUE |

|

Revolution |

3800 turns /min |

|

Chain |

#3 with 18 cogs (medium size) |

|

Working power |

1400W |

|

Power supply |

220v~250v,50Hz |

|

Net weight |

5.5 KG |

|

Minimum cutting size |

5MM |

|

Suitable paper |

all kinds of paper. Efficiency will be higher for corrugating medium paper/paperboard |

|

Gross Weight |

6.5KG |

|

Package Dimensions |

490*170*240mm |

HS-D10S electrical waste stripper’s main advantages compare to pneumatic strippers

1, Convenient. Easy to change position, no need to be fixed by air compressor position. You can use it whenever and everywhere and just need to contact the power that with 220V~250V.

2, No need to maintain it. Since it is connect to the power and there is no water vapor that may enter in the stripper.

3, Adjustable speed. There are 6 gears to adjust the speed. Easy and simple to operate with the speed you want.

Features of the electric waste stripper HS-D10S

⭐The electric waste stripper is a highly efficient post-press equipment, which greatly reduces labor costs.

⭐The chain made of high-strength alloy has extremely high hardness, strong wear resistance and long service life.

⭐The waste stripping machine is a very efficient electric waste stripping equipment, and the waste stripping efficiency is increased by nearly 10 times.

⭐The waste stripper has a compact structure, and its weight is similar to that of a common portable grinder.

⭐Using high-strength alloy, overheating process to process the sprocket, using electric motor all-copper core is not easy to burn, large fan to ensure good heat dissipation.

⭐Built-in powerful fan, through the suction fan, through the suction and exhaust mode to drive the air to achieve the effect of cooling.

“Our electrical”

The electric driven carton-stripper is our new electric type of carton-stripper. The electric stripper is particularly well suited for normal die-cut waste. This device is driven by a electric 1400 watts motor and is comparable in performance to the pneumatic stripper.

This device can be used wherever no compressed air system is available.

For the main processing of corrugated cardboard, we also offer our special large size and medium size of chain for this device.

This device is available only with the electrical requirements given in the technical specification below.

Picture show

OPTIMIZE THE STRIPPING PROZESS THE MOST EFFICIENT SOLUTION TO REMOVE DIECUT-WASTE.

Lightning-fast stripping of the outer die-cut waste from carton, microwave and corrugated board stacks with our carton-strippers.

Finish the time‐consuming and stressful waste‐stripping by hand. Our carton-strippers allows lightning fast removal of die‐cut waste from folding carton, e-flute, cardboard, microwave-and corrugated board. When breaking out the die-cut waste with our carton-strippers, the sheets remain exactly stacked as they left the die-cutter. Designed to meet the requirements of our customers, our carton-strippers have proven their worth in cartonboard and board processing worldwide for more than 15 years.

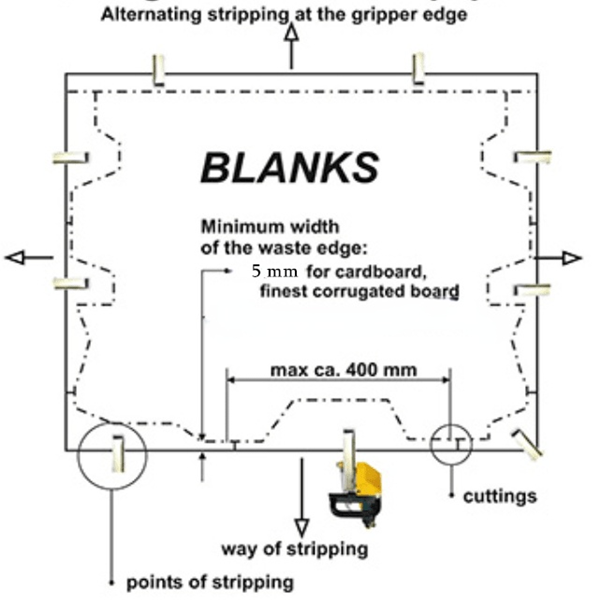

Requirements for using our technology.

Prerequisite for using our technology is that the outside trim must be cut into trim sections. Except from this is the clutch edge. This will be stripped out reciprocally, on the left and right side. Please see also the enclosed principle picture for waste segments. Subdivide the waste edge in a way that the chain can operate at the widest part of the waste edge. Furthermore, the smaller the number of nicks (to heed at new forms), the faster the stripping operation will go. The carton-stripper removes the trim section by section at high speed. A section of the stack of 250 sheets high can be removed in one second for instance. This performance results in a substantial lowering of manual stripping cost.

Handling of our carton-strippers.

The principle and handling is very simple.

The chain of the carton-stripper is placed with some pressure on the outer edge of the waste before the device is switched on.

The rotating, hardened and hard-chromed chain strips the exterior trim from the die-cut sheet at high speed.

Slide down the carton-stripper with some pressure on the waste trim.

Depending on the number of nicks and the breaks of the die-cut waste, you have to do a right / left combination with the carton-stripper to break out the die-cut waste along the full length of the stack. A chrome-plated cover over the chain prevents damage to the sheets and helps you to slide down the stack easily.

The reason why I recommend you to choose us

|

Chain |

Riveting Chain

|

more firmer and not hard to break. |

|

Metal Cover |

Stainless Steel Cover

|

it is easy to extremely hot and easy to dissipate heat, which can protect stripper by itself |

|

Metal Handle |

Stainless Steel Handle |

elegant and is high quality. |

|

Firm structure |

Three points fixation |

More firmer and more stable |

|

Inside components |

Hard Coating |

Longer lifetime and high quality |

|

Motor |

Taiwan Famous brand |

High accuracy, stability, and good quality |

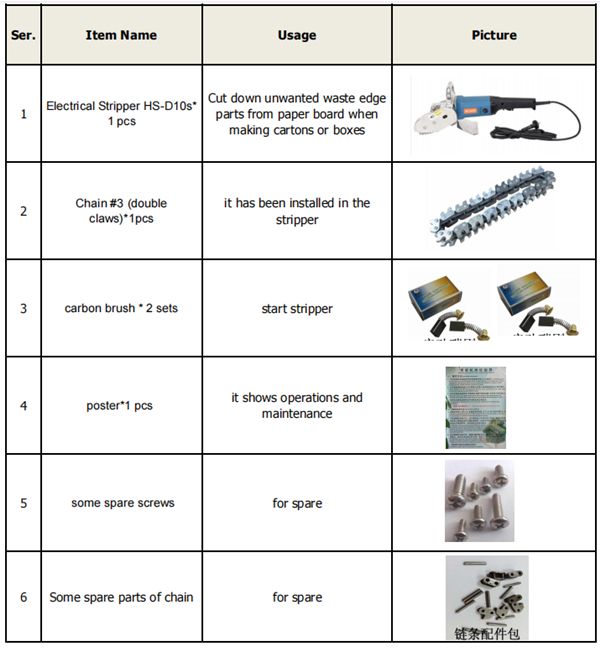

Order list

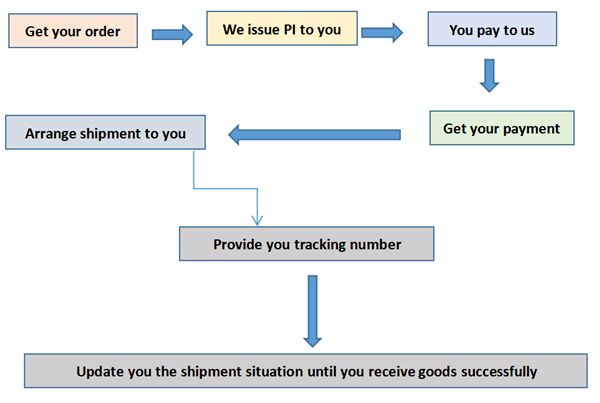

How to order to us and what’s the lead time?

1, once we got your order, we will issue you proforma invoice, if you need.

2, then, please arrange the payment for us and provide us the bank slip.

3, once we confirm your payment, we will arrange to send out stripper to you at once during business hours by FEDEX or DHL and provide you tracking number next day.

4, we will keep to follow the shipping details and update to you until you receive it successfully.

5, we will be on line 24 hrs a day and 7days a week for you.

6, We will contact you regularly to learn about the use situation of the machine in order to solve the problem in time

SHENZHEN CHAOYI MACHINE CO.,LTD

SHENZHEN CHAOYI MACHINE CO.,LTD