Pneumatic Waste Stripper Carton Boxes Die-Cut Waste Machine

Technical Specification

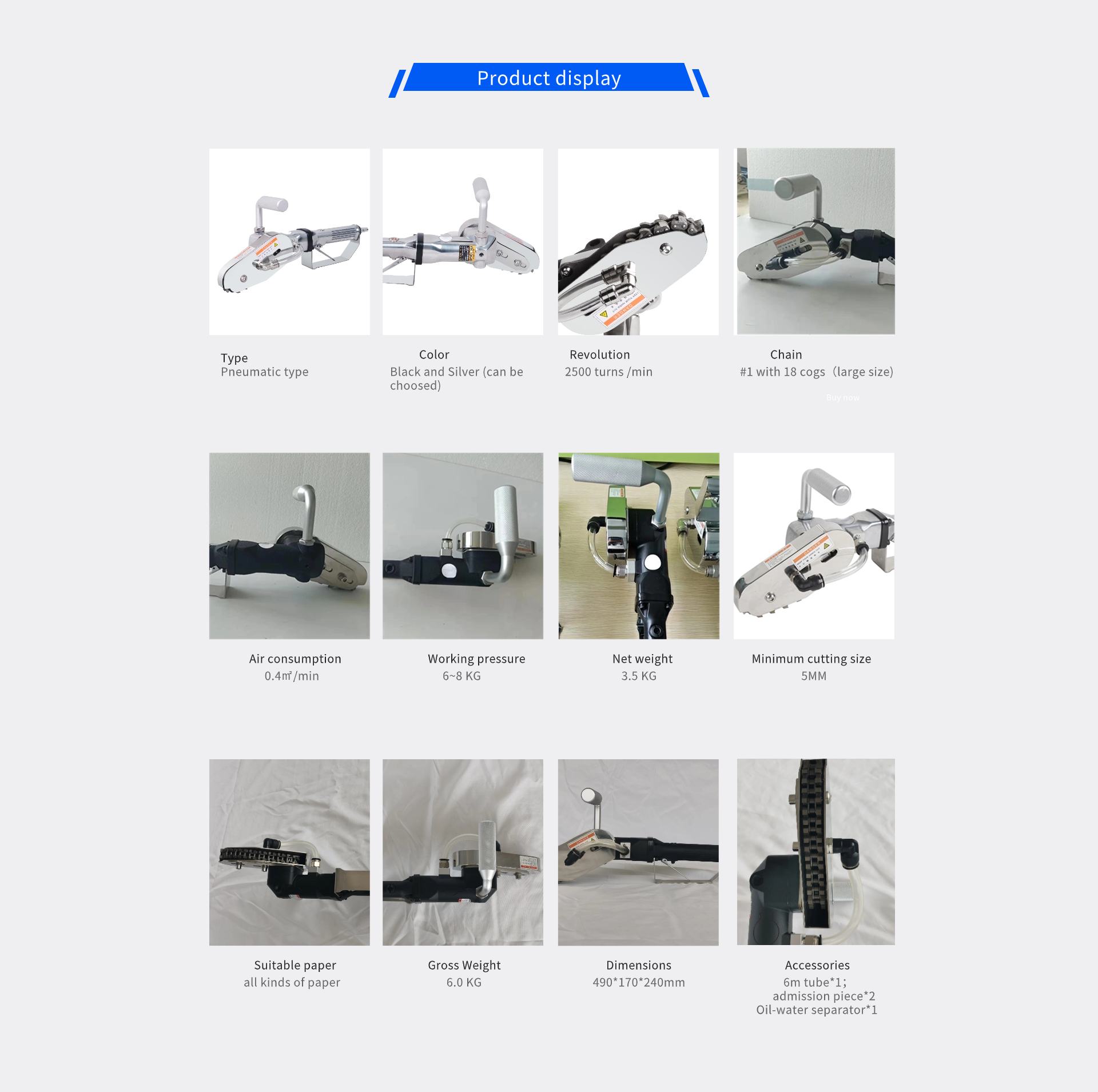

Product Code: CH-01

Product Type: Pneumatic stripping tool

Available Colors: Black and Silver (customizable)

Operating Speed: 2500 revolutions per minute

Chain Type: #1 with 18 large cogs

Air Consumption: 0.4 cubic meters per minute

Operating Pressure: 6 to 8 kilograms per square centimeter

Weight: 3.5 kilograms

Minimum Cutting Size: 5 millimeters

Compatible Materials: Suitable for all types of paper, with enhanced efficiency for grey board and corrugated medium paper

Total Weight (including packaging): 6.5 kilograms

Package Dimensions: 490*170*240mm

Product Description

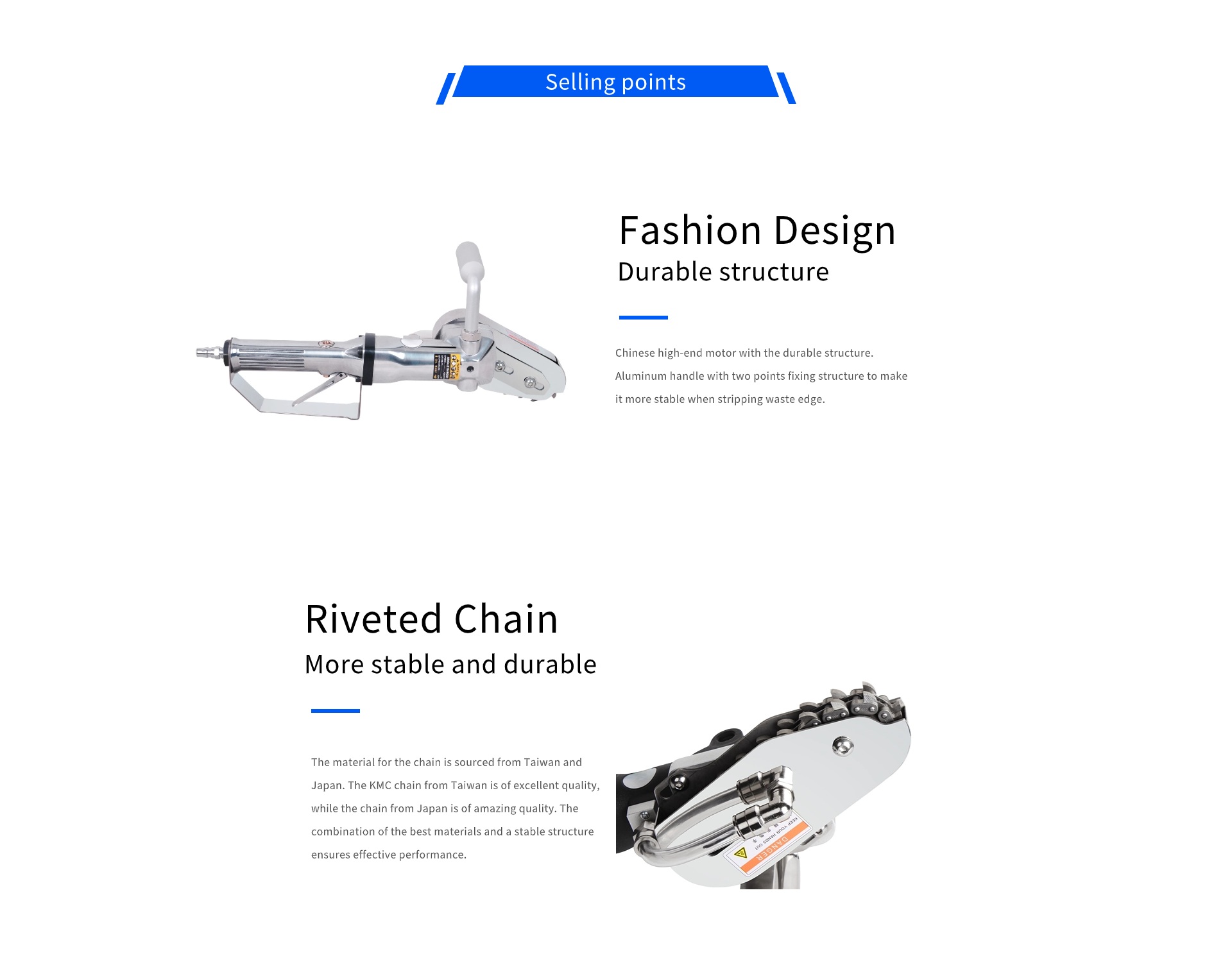

The CH-01 carton-stripper, powered by compressed air, features a slender and delicate chain, with a minimum waste edge width of 5mm. This stripper is designed for the removal of very small die-cut waste, particularly those buried deep within the stack, but is also suitable for normal waste removal.

Our pneumatic CH-01 models are highly durable and require minimal maintenance. For the US and UK markets, all pneumatic models are available with a two-handed safety system.

We are pleased to offer a lubrication unit for the CH-01 carton-stripper, which includes a filter with water separator, reduction valve, pressure gauge, air line lubricator, mounting bracket, and screws. The use of a lubrication unit is essential to protect the air-driven motor.

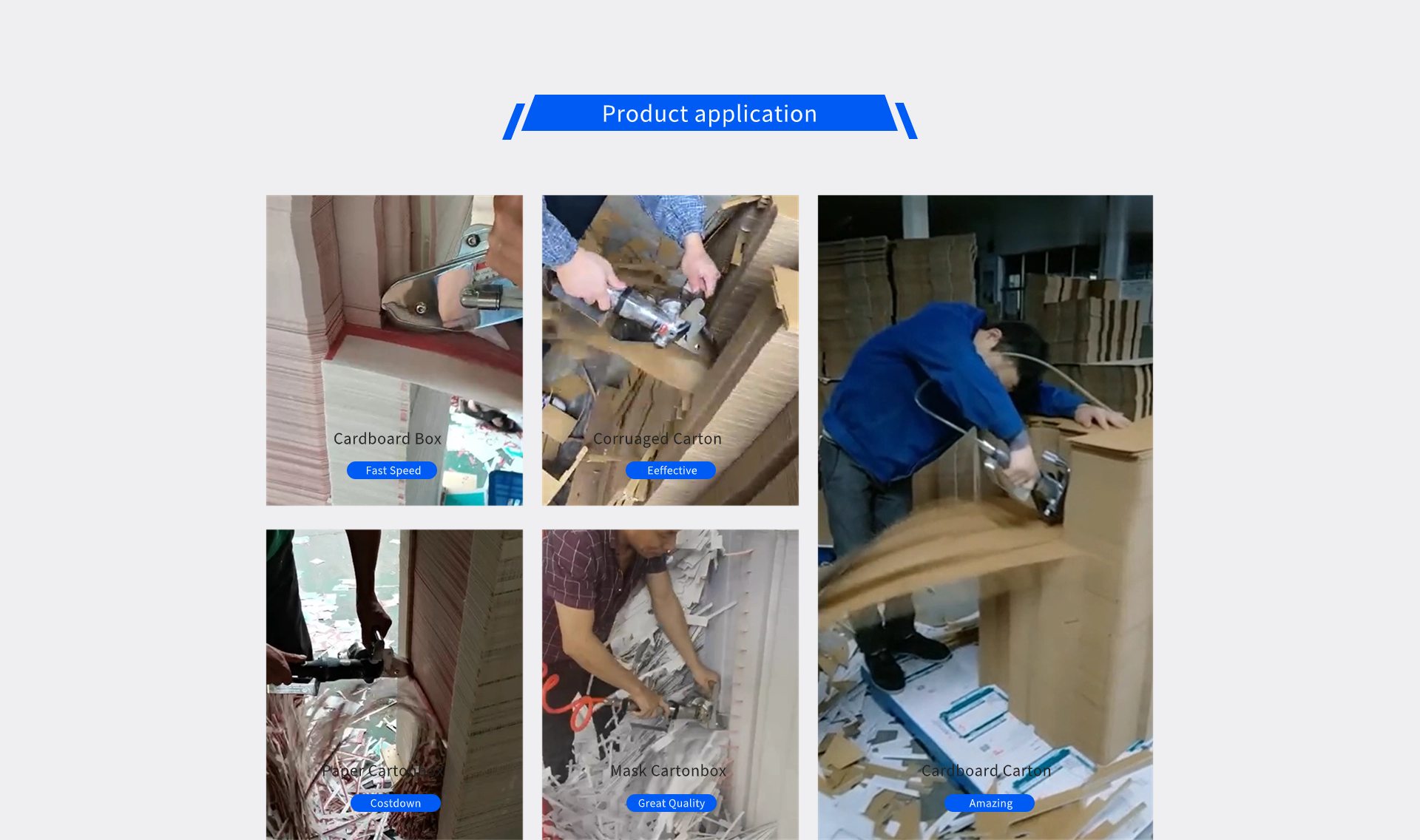

The CH-01 stripping tool provides an efficient solution for die-cut waste removal. It enables rapid removal of outer die-cut waste from cartons, craft paper, and corrugated board stacks.

Eliminate the time-consuming and labor-intensive process of manually removing waste. Our CH-01 carton-stripper allows for the swift removal of die-cut waste from folding cartons, e-flute, cardboard, microwave board, corrugated board, gray board paper, and craft paper. When using the CH-01 carton-stripper to remove die-cut waste, the sheets remain neatly stacked as they were when they left the die-cutter. Designed to meet the needs of our customers, our CH-01 carton-strippers have demonstrated their value in carton board and board processing worldwide for 15 years.

Requirements for using our technology

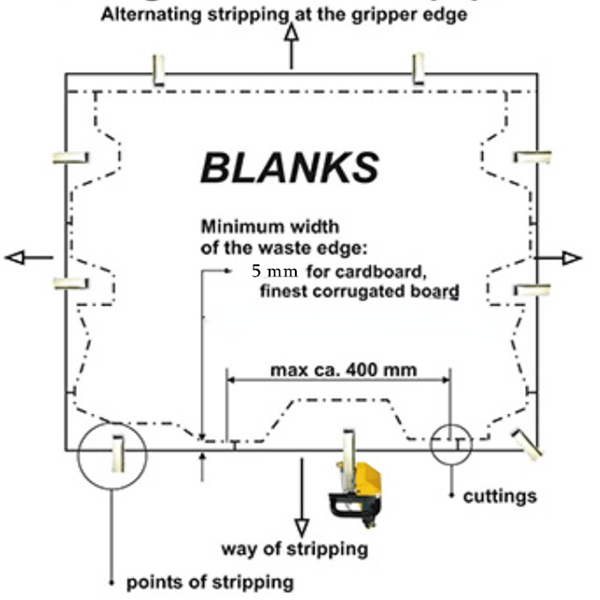

The prerequisite for using our technology is that the outer trim must be cut into trim sections, except for the clutch edge, which is reciprocally stripped out on the left and right sides. Please refer to the diagram below for waste segment illustration.

Divide the waste edge into sections to ensure that the chain can operate effectively across the widest part of the waste edge. Additionally, minimizing the number of nicks (to be mindful of with new forms) will increase the speed of the stripping operation. The HS-280 carton-stripper swiftly removes the trim section by section, achieving high-speed performance. For example, a section of a 250-sheet stack can be removed in just one second. This level of efficiency leads to a significant reduction in manual stripping costs.

Operating our CH-01 carton-strippers.

The operation and handling are straightforward.

Apply some pressure to the outer edge of the waste with the chain of the HS-280 carton-stripper before activating the device.

The rotating, hardened, and hard-chromed chain swiftly removes the exterior trim from the die-cut sheet.

Gently slide down the CH-01 carton-stripper with pressure on the waste trim.

Depending on the number of nicks and the breaks in the die-cut waste, you may need to use a right/left combination with the CH-01 carton-stripper to remove the die-cut waste along the full length of the stack. A chrome-plated cover over the chain prevents damage to the sheets and facilitates smooth sliding down the stack.

SHENZHEN CHAOYI MACHINE CO.,LTD

SHENZHEN CHAOYI MACHINE CO.,LTD