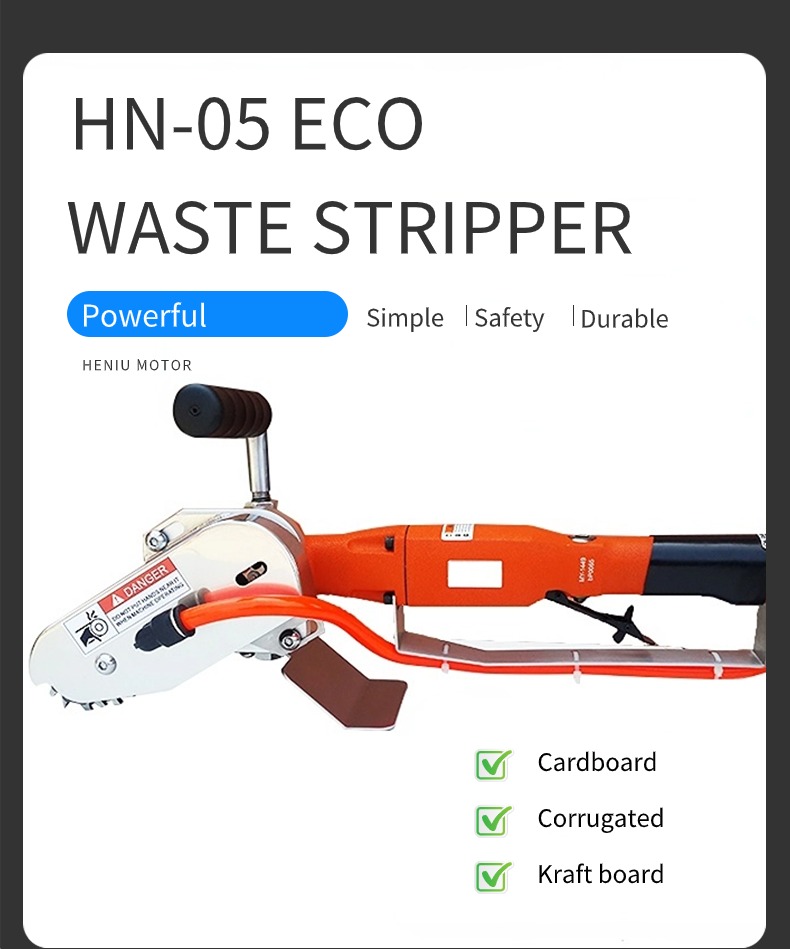

The paper waste stripping machine is a pneumatic device designed for removing waste edges from cardboard, fine corrugated, and standard corrugated paper in the printing sector. It serves as a substitute for manual hammers, enhancing work efficiency and reducing the time required for waste removal.

|

item

|

value

|

|

Warranty

|

1 Year

|

|

Type

|

Other

|

|

Applicable Industries

|

Packaging, printing, carton, box, paper roll

|

|

Video outgoing-inspection

|

Provided

|

|

Machinery Test Report

|

Provided

|

|

Warranty of core components

|

1 Year

|

|

Core Components

|

Bearing, Gearbox, Motor, Gear

|

|

Condition

|

New

|

|

Application

|

Machinery & Hardware

|

|

Packaging Type

|

Cartons

|

|

Packaging Material

|

Paper

|

|

Automatic Grade

|

Automatic

|

|

Driven Type

|

Pneumatic

|

|

Voltage

|

on client

|

|

Place of Origin

|

China

|

|

Brand Name

|

CHAOYI

|

|

Weight

|

6KG

|

|

Dimension(L*W*H)

|

450*200*250

|

|

Key Selling Points

|

High Productivity

|

|

|

The carton stripper provided a safe economic solution for stripping your waste paper of die cut sheets , cardboard and corrugated board .

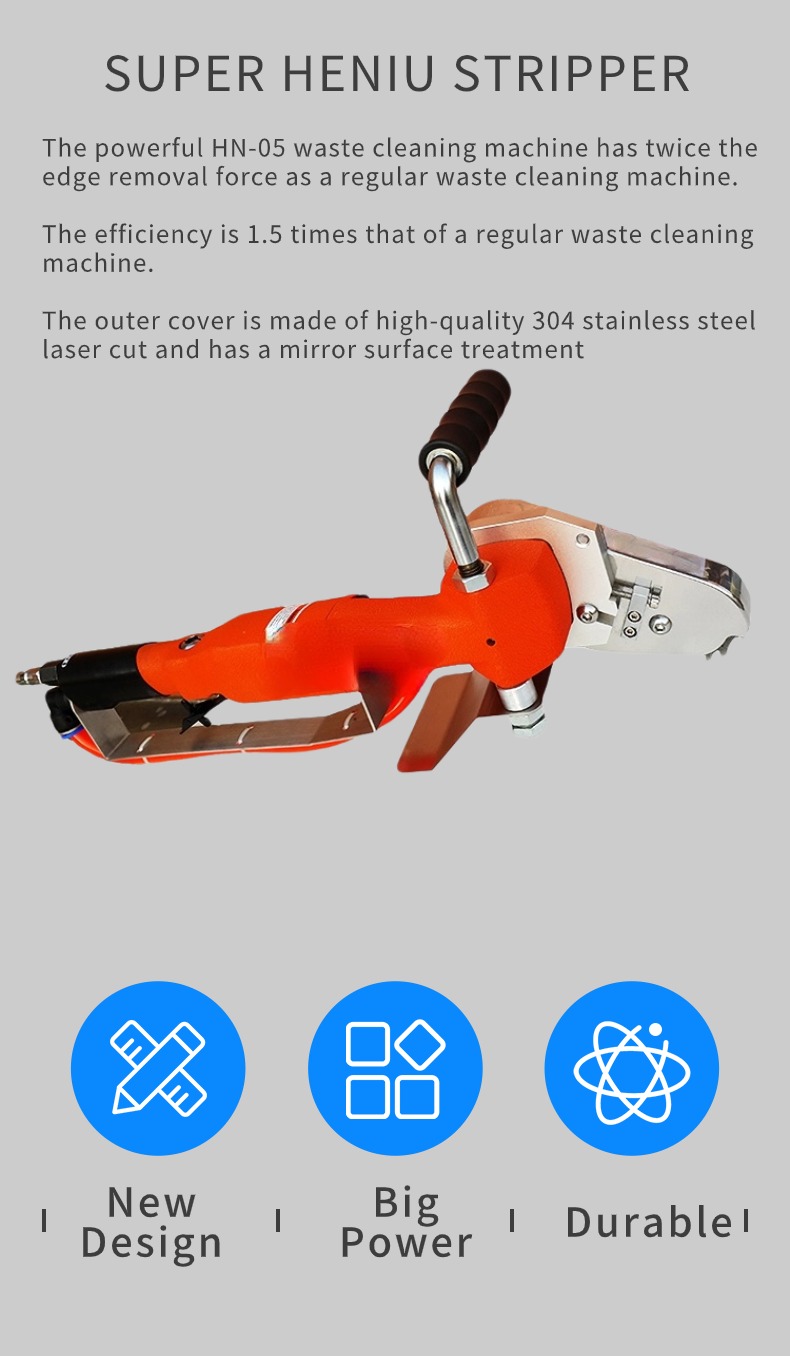

The waste stripper is equipped with multi tooth chain drive by a compressor air motor with an output 4500rpm, its teeth do not cut the paper ,they catch it , your operator just need to hold the device. The waste stripper quickly finished this work , up to 10times than by hand .

For waste margin stripping of cardboard, thin corrugated paper and common corrugated paper in printing industry, High-speed running gear is cycle driven through air motor , strip waste margin paper with sharp teeth gear. The gear use high strength Diamond Compound after heat treatment, high hardness, wear resistance, long life and easy replacement .

The product is high efficient manual stripping equipment, stripping efficiency is improved by 10 times, manual stripping needs hours, finished only in 10-30 minutes with stripping machine, greatly shorten the delivery cycle.

Compact configuration,almost the same weight as normal grinder,easy to use,worker can operate the machine after simple training, No damage for bonding area while stripping,improve the efficiency of the following process (gluing / automatic packing)

01 Requirements for use

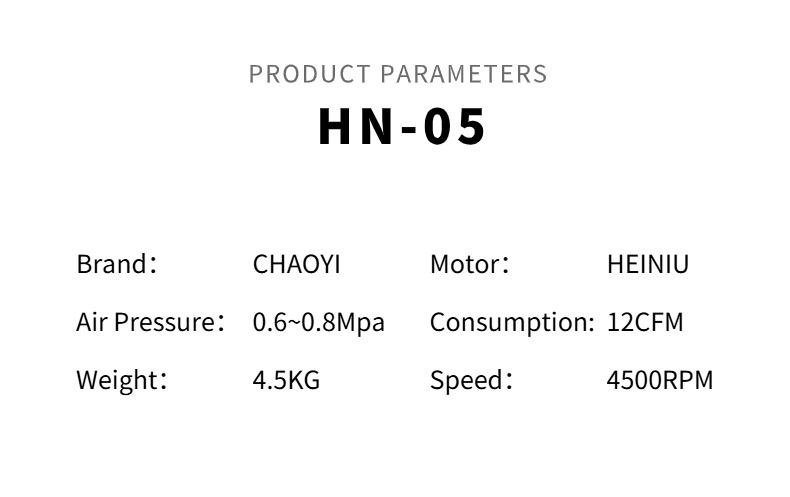

1. Air pressure: 0.6~0.8Mpa

Air compressor needs 4KW or 5.5HP or more

3. Production requirements for supporting die-cutting boards (very important!)

4. In order to work better with the waste stripper, the die-cutting board needs to be broken into several sections according to

the requirements, so that the stripper can quickly remove these small pieces of waste.

It is best to die-cut the external waste edges into small strips with a length of 250mm450mm. The specific length of the small

pieces is determined by the shape of the paper product, the width of the waste edges and the number of small sections. The smaller

the number of small blocks, the wider the width, the faster the waste removal speed.

02 Maintenance items

1 It is recommended to check the cleaning and maintenance tools every two months or so. Check whether the bearings, gears, chains

and other transmission parts are in good lubrication and clean. Then inject bone grease into the oil injection hole of the motor

head to make the internal gears of the motor fully lubricated. If the motor tool is used in high frequency, it is recommended that

the tool be routinely checked and lubricated every two weeks.

2. Regularly clean the air motor blades according to different usage conditions. The cleaning method is: loosen the air inlet

pipe, inject a small amount of less viscous lubricant from the air inlet, connect the air pipe, and run for 30 seconds, then

loosen the air pipe to pour out the dirty oil , And then drip a small amount of lubricating oil, you can also inject and

other bone moisturizing agents from the exhaust port.

3. If the tool is placed for a long time, it is not necessary to drip a small amount of lubricating oil from the air inlet, and

then let the tool run for a few seconds before storing the tool so that the internal parts of the tool will remain lubricated and

rust-proof

Precautions

(1) After using every day, spray WD-40 anti-rust oil on the chain to clean the chain, use a dust blow gun to blow off the paper

dust, and then add a little lubricating oil. Careful maintenance can extend the life of the chain (very important ).

(2) Handling of jammed paper: Disconnect the air circuit (very important). If the chain cannot be turned, loosen the protective

shell screws and take out each screw, turn the rail to remove the jammed paper and install the screws to continue using.

(3) The tension of the chain must be checked frequently, and the tension should be adjusted when necessary. After adjustment, if

the longest section of the chain sags about 1mm in a horizontal state, it indicates that the tension adjustment is basically

correct. A chain that is too loose will damage each other with the collision surface of the safety shield during rotation.

Pneumatic stripping machine for scale and precautions:

1. Firstly, the paper should be piled up in order to eliminate the waste. The four sides are flush, and the four sides need to have a knife edge. The spacing between the knife edge and the knife edge is suitable for the paper to be easily stacked. The knife edge is properly organized to form a gap, so that the waste edge is connected with the product. It is necessary to use z5mm when clearing the edge and make a break.

2. Applicable paper scale: 200g/m-500g/m cardboard, single/double pit paper, double-pitched crepe paper.

Pneumatic waste disposal machine application tips:

1. The user installs the air compressor by himself. In order to make the machine work safely for a long time, please input the pressure of the compressed air of the machine.

0.63Mpa, and through boring disposal, it is recommended that the customer device use the air filter combination (two pieces) to connect to the air compressor output.

2. Always remove paper dust or dust adhering to the gap of the machine to keep the machine working properly.

Pneumatic waste disposal machine application instructions:

1. Pneumatic tools are not maintained in maintenance.

2. Pneumatic stripper is different from other pneumatic tools. After one week of running-in period, and always adhere to the unimpeded sliding of the chain and sprocket, the chain is given every half day. Add a few drops of gear oil to reduce the conflict, and then extend its application time.

3. Firstly, the machine is connected with the gas source to ensure that the air pressure is 6-8 kg, and the air pipe demand is 8*12M/M.

4. Before the air pressure is not opened, can the chain be freely rolled by hand, otherwise it can not be used. After adjusting the direction of the paper-cutting machine, fix the locking screw so that it cannot swing.

5. Every day before and after work, you must drop three to four drops of special oil for pneumatic tools from the air inlet and idle for 2-3 seconds.

FAQ:

Q1 :Are you the trader or manufacturer?

A. we are the manufacturer with export qualification

Q2 Do you make OEM?

A. Yes,here can do

Q3. Where are your factory located in ?

A . we are in Shenzhne ,China

Q4 Where is the nearest airport of factory ?

A.Here nearest airport ,Yantian,shekou in shenzhen.

Q5 Where is the nearest high-speed train station? How long from high speed train to factory ?

A. Shenzhen North, about 1 hours.

Q6 .What is your business process?

A.Talking about clients requirements, confrim machines,make sales contract,pay for deposit, supplier arrange production, finish producing machines,buyer test machines, buyer pay for the balance payment,supplier delivery machine

Q7 How to control machine quality ?

A. 1)CHAOYI company’s life is machine quality,have strict quality control system from production to delivery

2)All material are environmental protection,non-pollution

3)We have professional technicist for supervising to production

4)Have professional department to examine about every production process

Q8 Engineer can go abroad for debugging machine?

A.Our engineers can go abroad for debugging machine,buy need buyer to bear the engineers round trip ticket,room and board ,80usd/day for salary.

SHENZHEN CHAOYI MACHINE CO.,LTD

SHENZHEN CHAOYI MACHINE CO.,LTD