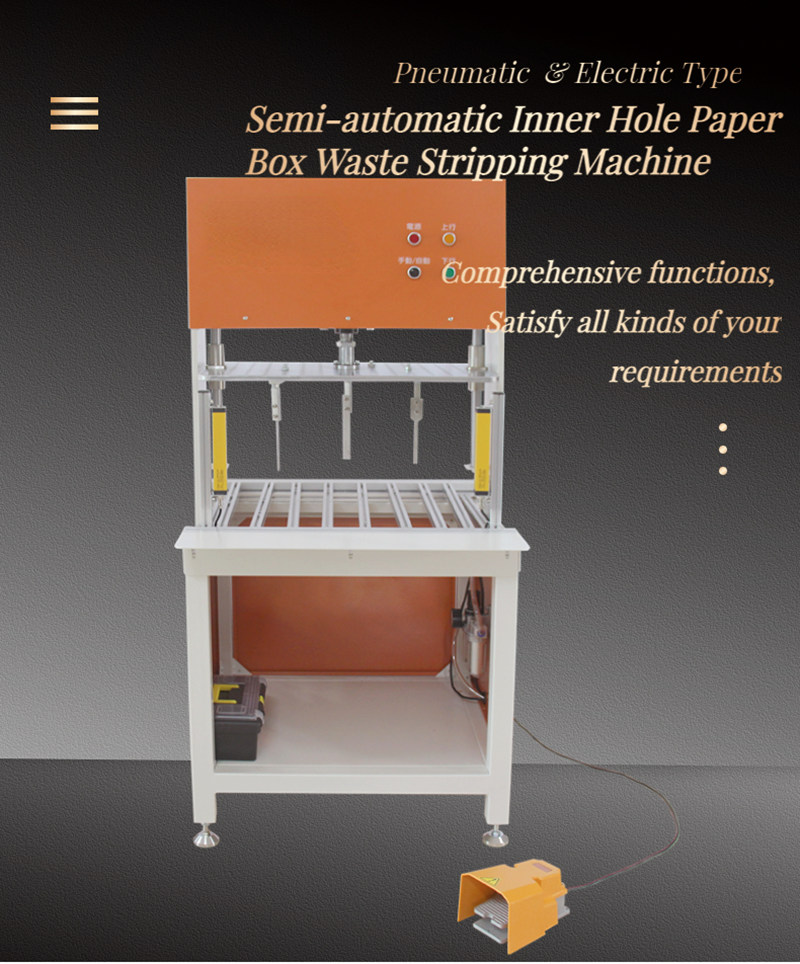

The HS-650 Semi-automatic inner hole waste stripping machine

The HS-650 Semi-automatic inner hole waste stripping machine is an innovative solution designed specifically to address the issue of inner hole waste in the packaging and printing industry.

Type: Inner hole waste stripper

Voltage: 220V

Air Pressure: 0.8 BAR

Machine Stress:1.5T

Working Distance of Travel: 150MM

Working Area Size: 750*550MM

Machine Dimensions: 740*660*1550MM

Net Weight: 160KG

Gross Weight: 213KG

Package Dimension: 1790*870*870mm (1.4 CBM)

Package:Export wooden box

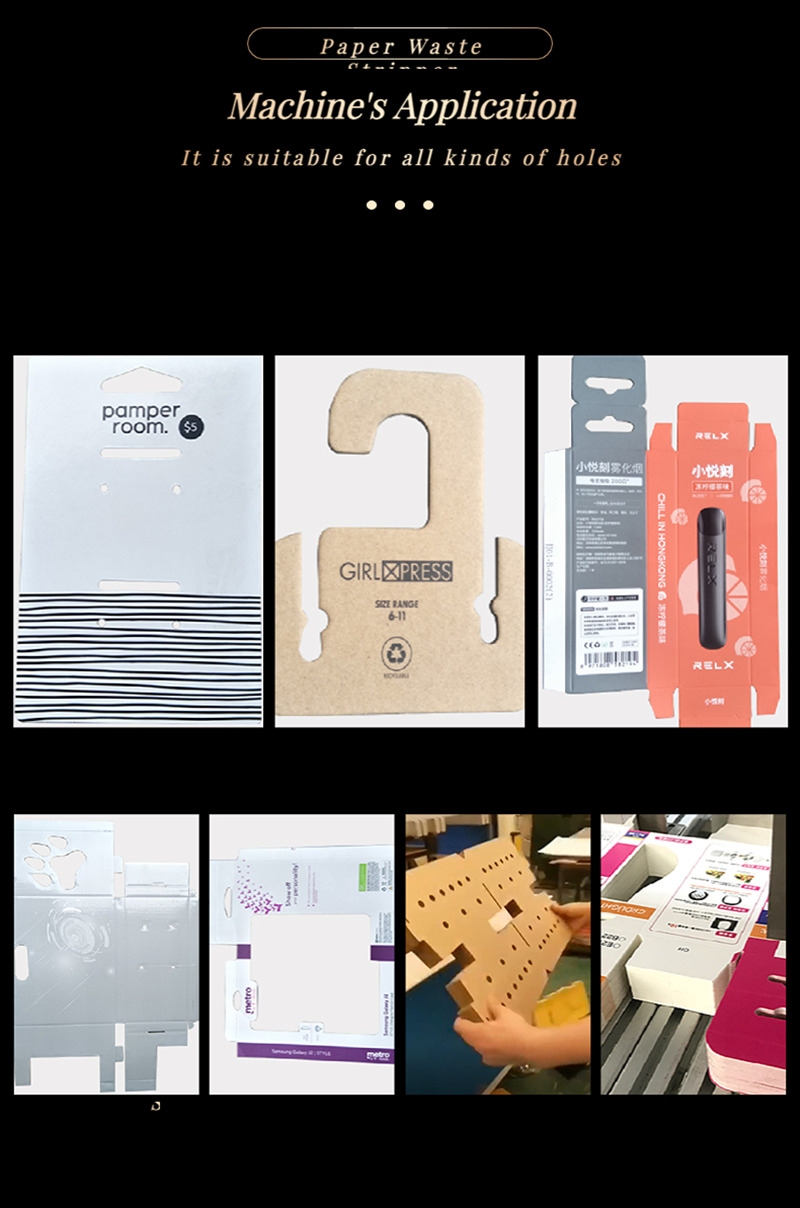

This state-of-the-art machine is specifically designed to remove inner hole waste from various materials such as paperboard, corrugated boxes, cartons, and other materials commonly used in the industry. With its exceptional capabilities and unmatched precision, the HS-650 Semi-automatic inner hole waste stripping machine represents a crucial piece of equipment for any operation handling large quantities of paper or cardboard.

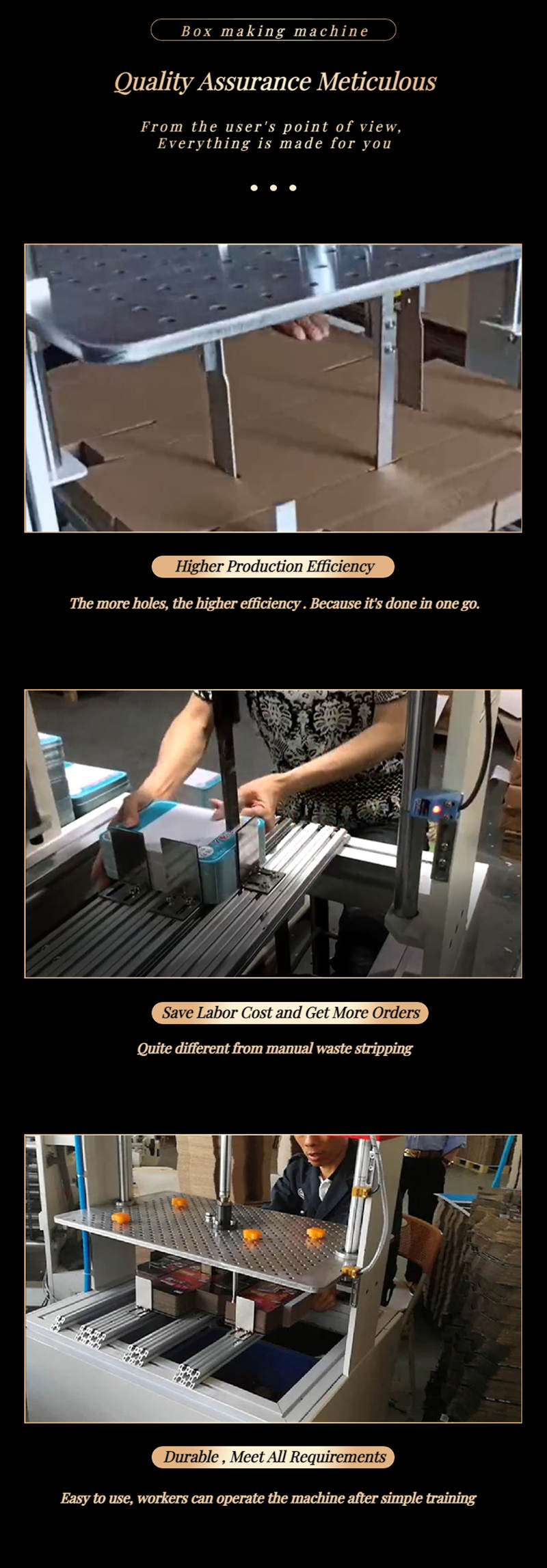

The HS-650 Semi-automatic inner hole waste stripping machine has been engineered with the highest standards of quality and precision. It is equipped with advanced features that make it a reliable and efficient solution for removing inner hole waste. The machine is semi-automatic, which means that it is capable of handling large volumes of material without requiring constant intervention from operators.

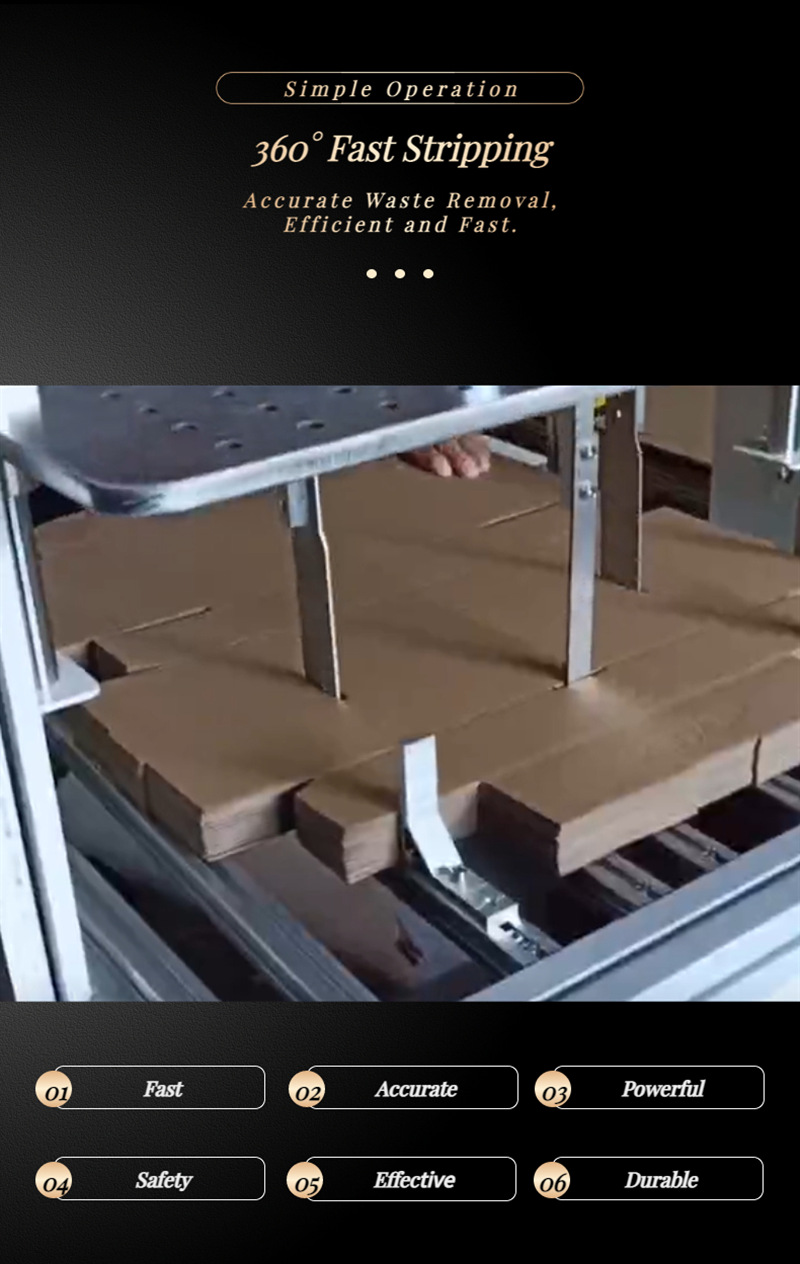

The machine is also highly adaptable and can be customised to suit the specific needs of each and every operation.One of the most significant advantages of the HS-650 Semi-automatic inner hole waste stripping machine is its ability to handle a wide variety of materials.

The machine can effectively remove inner hole waste from materials with different thicknesses, densities, and textures. This feature means that the machine can be used to handle a wide variety of products, making it an extremely versatile solution for any operation.Another significant advantage of the HS-650 Semi-automatic inner hole waste stripping machine is the high level of precision, accuracy and quality it delivers.

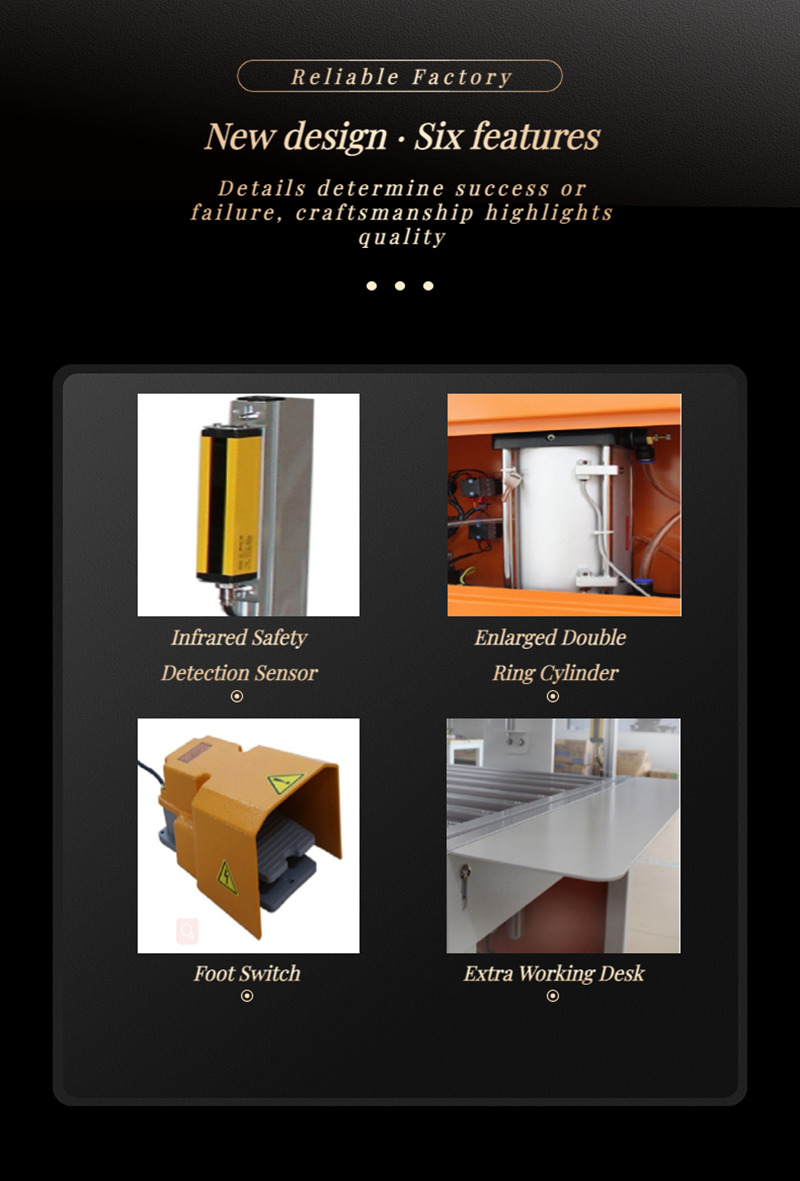

The machine is equipped with advanced sensors that enable it to detect inner holes with exceptional accuracy. This detection technology ensures that only the precisely marked inner holes are removed, leaving the final product with an unparalleled level of quality.In addition to its advanced technological features, the HS-650 Semi-automatic inner hole waste stripping machine is also highly reliable and durable.

Constructed from high-quality materials and engineered to withstand even the most demanding operating conditions, the machine is capable of delivering years of high-performance operation without any significant maintenance or repairs required.The HS-650 Semi-automatic inner hole waste stripping machine is designed to be easy to operate, with an intuitive interface that simplifies the process of removing inner hole waste from materials.

The machine is also lightweight and compact, making it easy to move around and set up in various locations wherever it is required.Overall, the HS-650 Semi-automatic inner hole waste stripping machine represents a significant advancement in the packaging and printing industry.

With its advanced features and exceptional capabilities, this machine is poised to revolutionise the industry and help businesses to achieve new levels of efficiency and productivity. Whether you are a small business or a large, industrial-scale operation, the HS-650 Semi-automatic inner hole waste stripping machine is an excellent investment that will pay off in the long term by ensuring quality and cost-effectiveness.

SHENZHEN CHAOYI MACHINE CO.,LTD

SHENZHEN CHAOYI MACHINE CO.,LTD