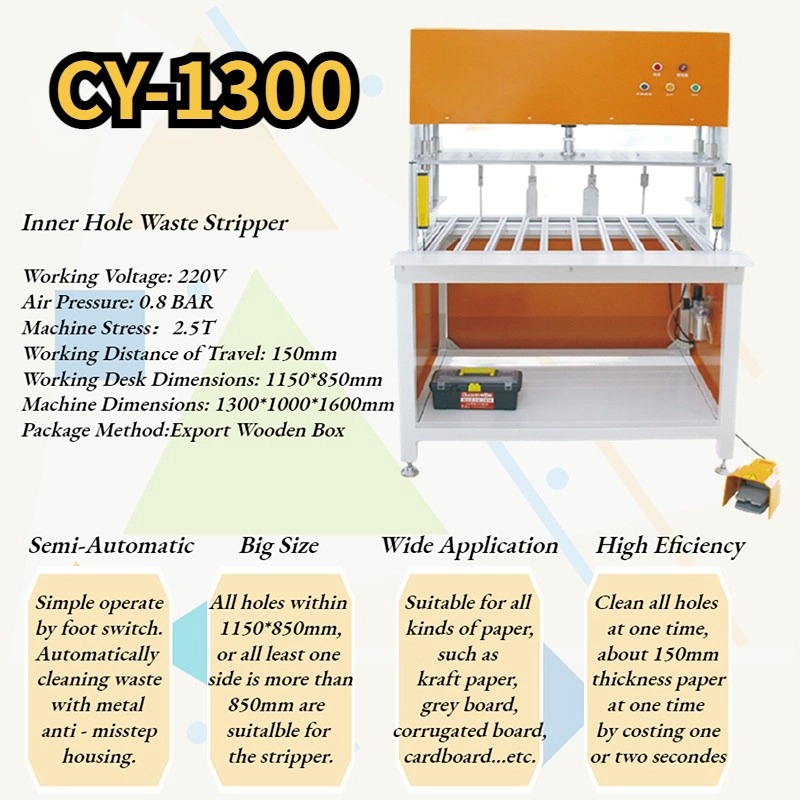

Automatic Box Waste Stripping Machine Air Waste Stripper

Technical Information

|

Name |

Split-hole Waste Carton Stripper |

|

Item No. |

CY-1300 |

|

Voltage |

220V |

|

Atmospheric |

0.8BAR |

|

Pressure |

2.5T |

|

Course |

150MM |

|

Working Size |

1150*850MM

|

|

Contour Size |

1300*1000*1600MM

|

Product Details

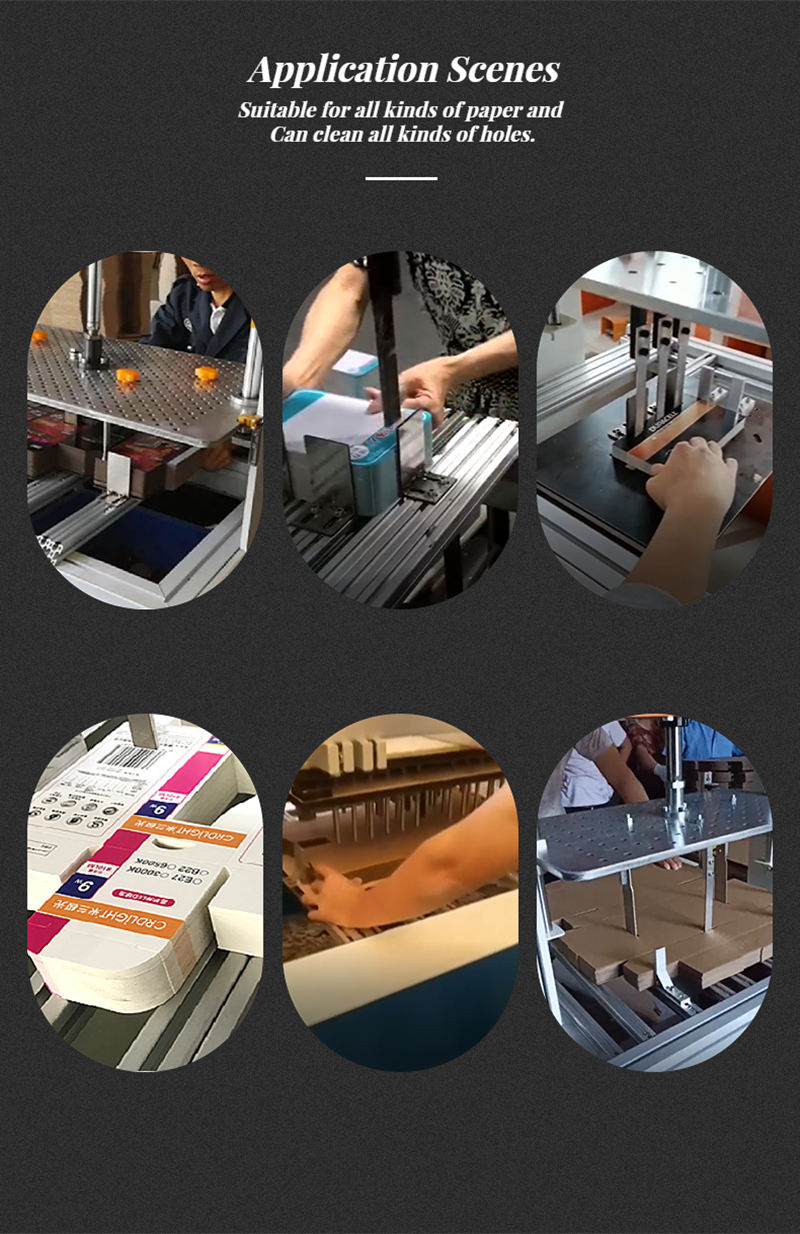

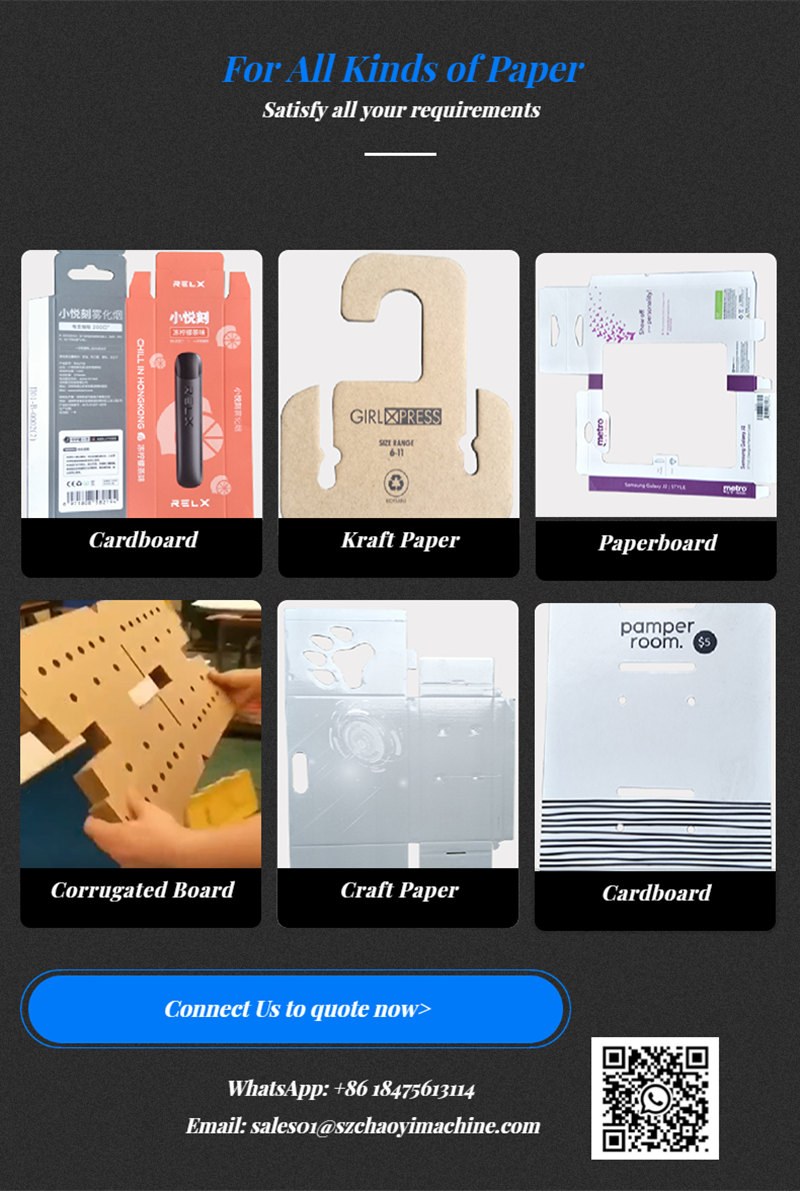

CY-1300 is a Pneumatic stripping machine is used to separate the excess part of paper, corrugated cardboard, foil, plastic, foam, or rubber. The design of the machine allows the attachment of various types and shapes of peeling tools and separation plate. The device has a precise vertical guidance of the stripping plate. The table is equipped with movable stops on the processed material.

At the same time, it is also a semi-automatic waste removal and inner hole removal machine, which is a special waste removal tool for color box tag aircraft holes.

It is mainly used for the cleaning of waste paper in the inner hole after die-cutting of various color boxes and cartons of color printing and packaging enterprises (such as plane holes, round holes, square holes, long strip holes, heterosexual holes, etc.).

Many key parts are designed and processed to ensure the accuracy of mechanical work and easy operation. The adjustable locking plate can install dozens of molds at the same time to clear dozens of waste holes at a time, which greatly saves labor and improves work efficiency.

The efficiency and benefits bring to you by the semi-automatic waste cleaning machine are as follows:

Reduce manual waste removal and save labor for you;

Reduce the loss of products caused by manual waste removal and improve product quality;

The actual production efficiency of the machine is increased by 30%-50%;

For products with more holes, the efficiency of the machine's waste removal is more advantageous. The machine is completely cleaned at one time regardless of the number of holes, which is different from the traditional manual waste removal machine. With traditional manual waste removal machines, the more holes there are, the longer the manual waste removal time and the lower the efficiency.

The semi-automatic waste removal inner hole machine has a compact structure, simple operation and very convenient use. Male and female employees can take up their posts after simple training.

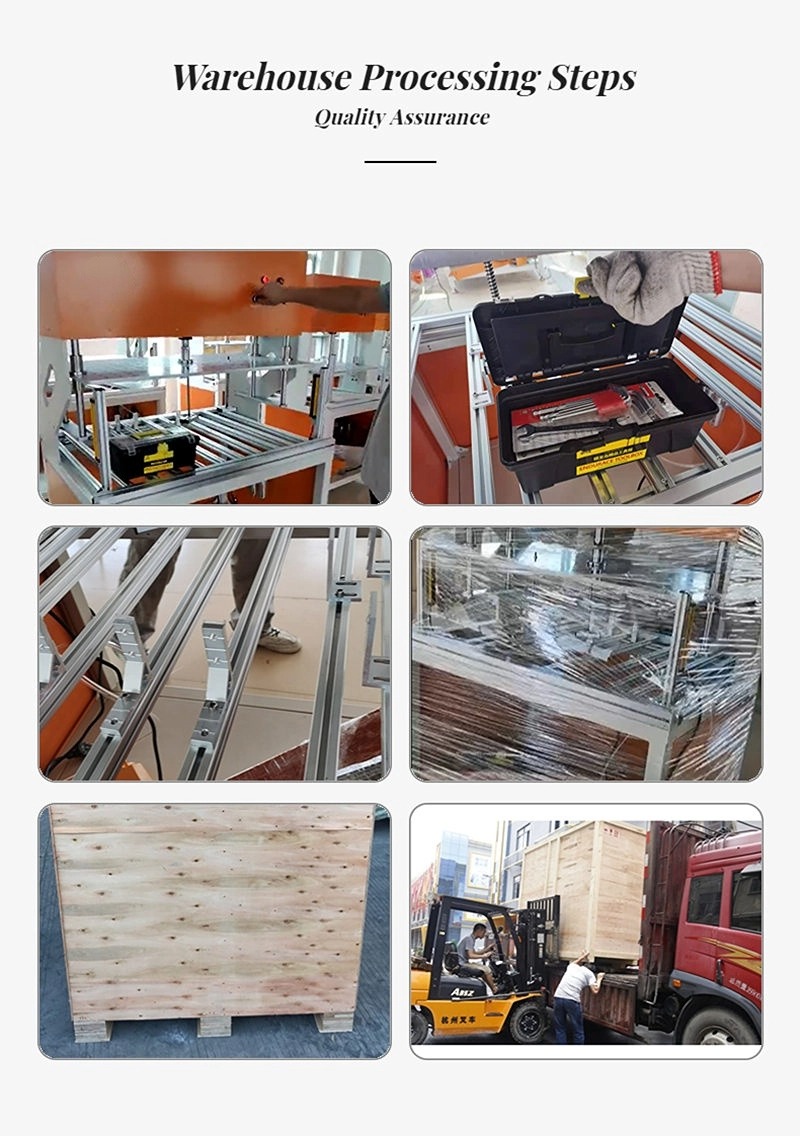

The machine is easy to debug, safe and convenient

1, Cycle start by foot pedal + active safety light barriers

2, Simple operation, all functions are controlled by the control panel

3, Light beacon to indicate the status of the device

4, Manual loading of the processed material

5, Quick adjustment to new production

6, Easy disposal of waste into a waste container

7, The possibility of using universal or single-purpose peeling tools and boards

8, Soft holding of the material before the movement of the press - fixation of the material without the need for manual holding

9, Ideal also for smaller jobs thank to quick changeover time

10, Safety optical barrier preventing unauthorized starting of the machine by the operator

11, Service input from the rear of the machine

CY-1300 Photos Show

Why choose us?

1, Infrared Safety Detection Sensor

If the hand is not taken out of the woking desk, the sensor will prevent the machine from pressing down, which will keep safety of production.

2, The Large Size double Magnetic Ring Cylinder

125 type cylinder is adopted to make the machine work more stable and remove waste paper smoother.

3, Foot Switch

High - grade foot switch automatically cleaning waste, with metal anti - misstep housing.

4, Extra Working Desk

Widen the material preparation table can be used to put aside the product. It can increase the product drag and drop length, which will be more convenient to clear the waste.

CY-1300 Advantage

1, Reduce artificial waste.

2, Reduce manpower waste when damage to the product.

3, 40%-60% higher production efficiency.

4, The more holes, the higher efficiency cost it's done in one go. Quite different from manual waste stripping . Special mould and needles are available upon demands.

5, Compact configuration,easy to use, men and women can operate the machine after simple training.

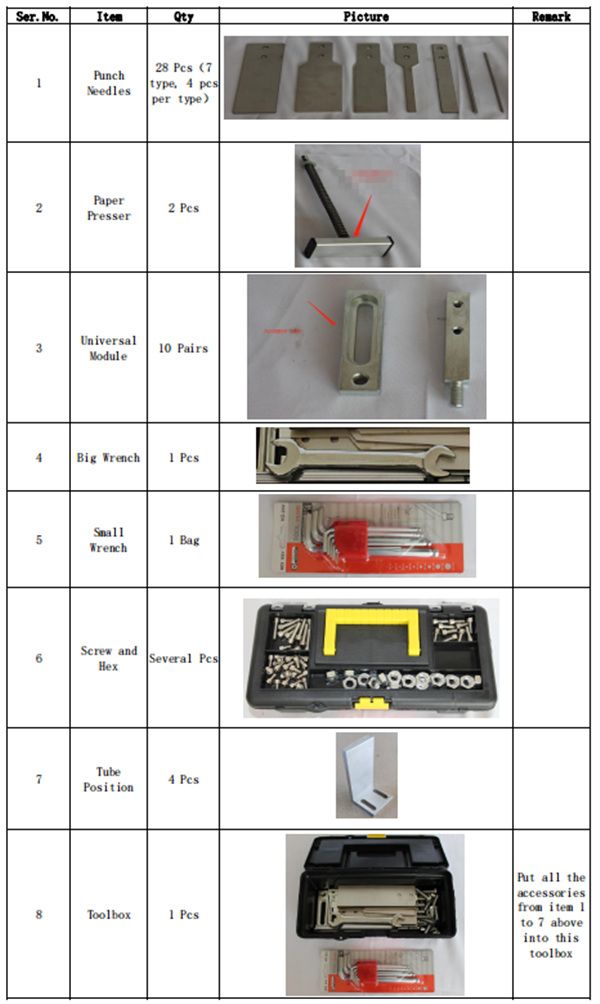

Accessory List

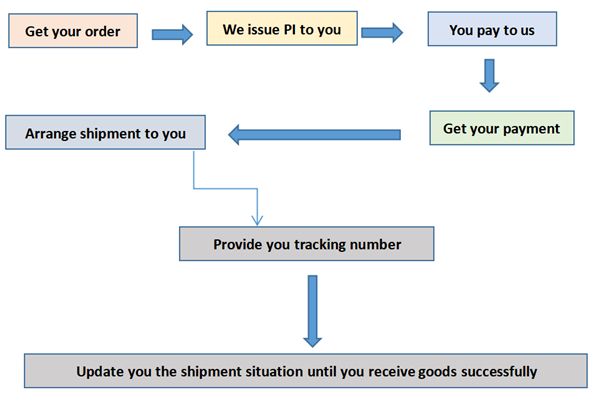

Order Steps

SHENZHEN CHAOYI MACHINE CO.,LTD

SHENZHEN CHAOYI MACHINE CO.,LTD