High-Speed Inner Hole Waste Removal Machine for Paper Products

This machine is mainly used for color printing and packaging enterprises of various color boxes and cartons after die-cutting the residual inner hole (round hole, square hole, long hole, airplane hole, shaped hole ...) The removal of waste paper. Applicable to hangtags, cartons, color boxes .... One or more holes can be cleared.

Advantages of Haoris hole cleaning machine and inner hole waste removal machine

Feature

1、High accuracy and easy operation.

2、The mold can be customized, the punching die can be increased and reduced, dozens of molds can be installed at the same time to achieve a cleanup of dozens of waste holes. Multiple holes can be cleared at the same time to improve work efficiency.

3、The punching die produces pressure on the product without destroying the integrity of the product.

4、Cleaning box can be built in.

|

Model

|

CY-730

|

CY-480

|

CY-680

|

CY-1200

|

|

Maximum paper size(mm)

|

780x700

|

520x500

|

1280x800

|

1720x1360

|

|

Minimum paper size(mm)

|

30x30

|

30x30

|

30x30

|

30x30

|

|

Maximum waste removal width(mm)

|

730 x 580

|

480x380

|

1200 x 680

|

1680x1200

|

|

Maximum stacking height(mm)

|

80

|

80

|

80

|

80

|

|

Workbench height(mm)

|

800

|

800

|

800

|

800

|

|

Minimum clear bore aperture(mm)

|

2

|

2

|

2

|

3

|

|

Maximum pressure(kg)

|

730

|

470

|

730

|

1800

|

|

External dimensions(mm)

|

700x900x1600

|

640x500x1600

|

1400x800x1650

|

1360x1860x1830

|

|

Machine net weight(kg)

|

220

|

120

|

300

|

400

|

|

Supply Voltage(v)

|

220

|

220

|

220

|

220

|

|

Frequency(HZ)

|

40-60

|

40-60

|

40-60

|

40-60

|

|

Maximum power consumption(w)

|

3

|

3

|

3

|

3

|

|

Gas consumption(L/min)

|

3-5

|

3-5

|

3-5

|

3-5

|

|

Compressed air(bar)

|

5-8

|

5-8

|

5-8

|

5-8

|

|

Size after packing

|

(L)800x(W)1000x(H)1750mm

|

(L)750x(W)600x(H)1750mm

|

(L)1500x(W)900x(H)1800mm

|

(L)1460x(W)1960x(H)1980m

|

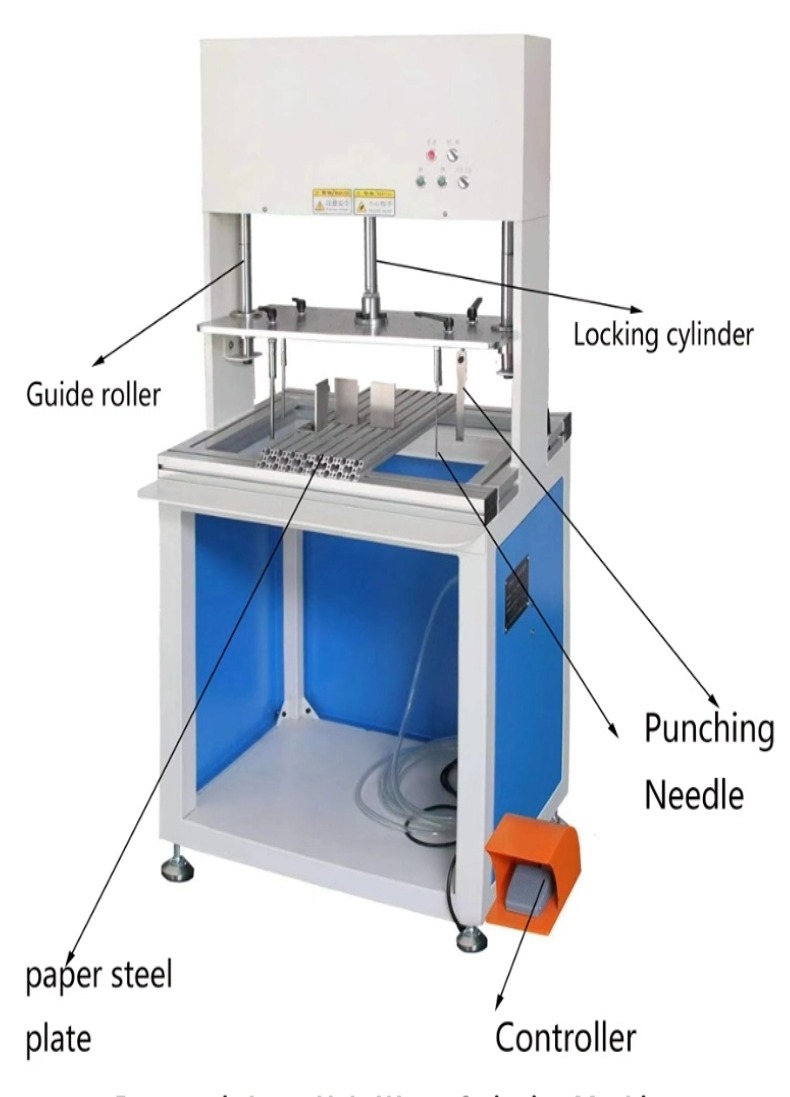

Pneumatic Inner Hole Waste Stripping

Machine**Pneumatic internal waste removal machine**

The pneumatic inner hole waste remover is specially designed for color printing and packaging companies. It can efficiently remove the residual waste paper after die-cutting of various color boxes and cartons. It can handle a variety of hole shapes such as round, square, long, airplane, and customized. It is suitable for applications such as tags, cartons, and color boxes. It can clean one or more holes at the same time.

**Main Features**

1. **High Precision and User-Friendly Operation**: The machine is precisely designed to ensure efficient waste removal while being easy to operate for users of all skill levels.

2. **Customizable molds**: The machine supports customized molds, and punching molds can be added or reduced as needed. Dozens of molds can be installed at the same time, and multiple waste holes can be cleaned at one time, greatly improving work efficiency.

3. **Gently Apply Pressure**: The punching die applies pressure to the product without compromising its structural integrity, ensuring the quality of the box remains intact during the waste removal process.

4. **Built-in cleaning box**: An optional built-in cleaning box further simplifies the waste removal process, making it more efficient and organized.

**Advantages of Pneumatic Internal Hole Waste Remover:**

- **Increased Productivity**: By cleaning multiple holes simultaneously, the machine significantly increases overall productivity in the packaging process.

- **Labor cost savings**: The semi-automatic design means only one operator is needed to manage the machine, reducing the number of workers required for waste removal tasks and lowering labor costs.

- **Enhanced Safety and Ergonomics**: The machine’s design minimizes physical strain on the operator, reducing the risk of work-related injuries and improving workplace safety.

- **Versatility**: The machine adapts to various types of packaging materials and hole shapes, making it a valuable asset to any color printing and packaging business.

In summary, the pneumatic internal hole waste discharger is an essential tool for the color printing and packaging industry to improve efficiency and productivity. Its advanced functions and user-friendly design make it a reliable choice for companies seeking to optimize the waste discharge process.

CY-680 Photos Show

Why choose us?

Infrared Safety Detection Sensor

The sensor prevents the machine from pressing down if the hand is not removed from the working desk, ensuring production safety.

Large Size Double Magnetic Ring Cylinder

The adoption of the 125-type cylinder ensures stable machine operation and smoother waste paper removal.

Foot Switch

The high-grade foot switch enables automatic waste cleaning, featuring a metal anti-misstep housing.

Additional Working Desk

Expanding the material preparation table provides space to set aside the product, increasing the product drag and drop length for more convenient waste clearance.

CY-680 Advantages

Minimize manual waste removal.

Reduce labor costs associated with product damage.

Achieve 40%-60% higher production efficiency.

Higher efficiency for products with multiple holes, as it can be completed in one go, unlike manual waste stripping. Special molds and needles are available upon request.

Compact design, user-friendly operation, suitable for both male and female operators after basic training.

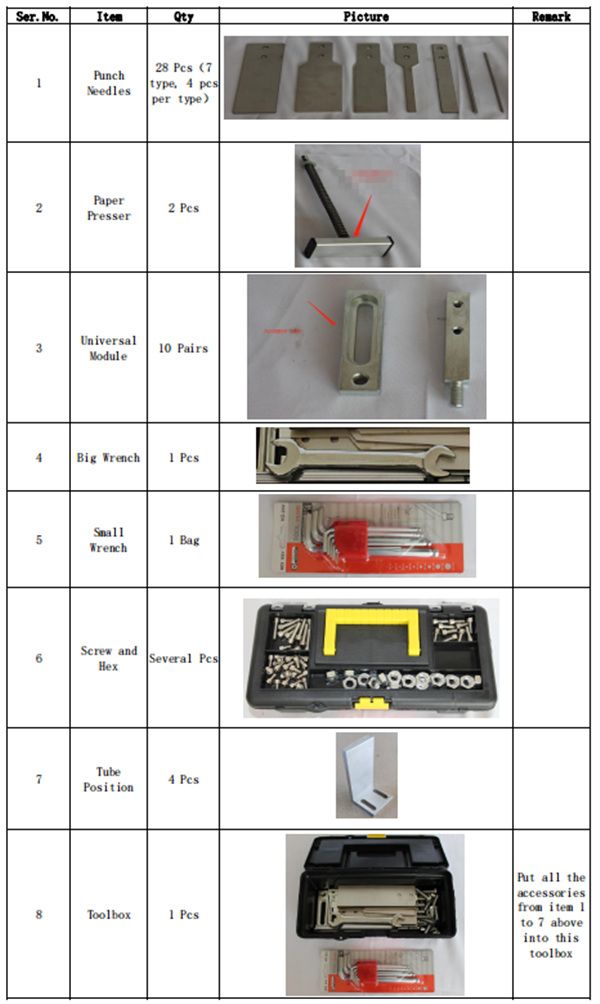

Accessory List

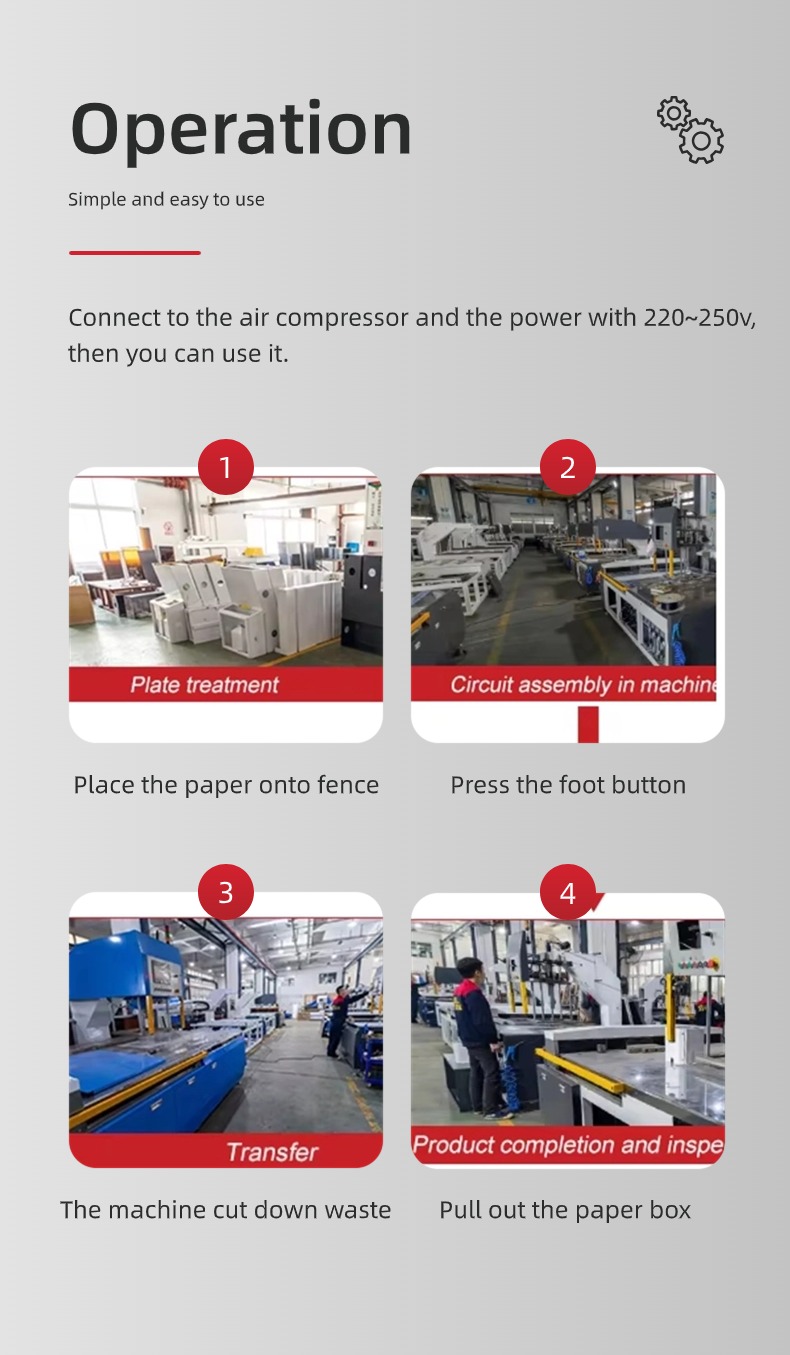

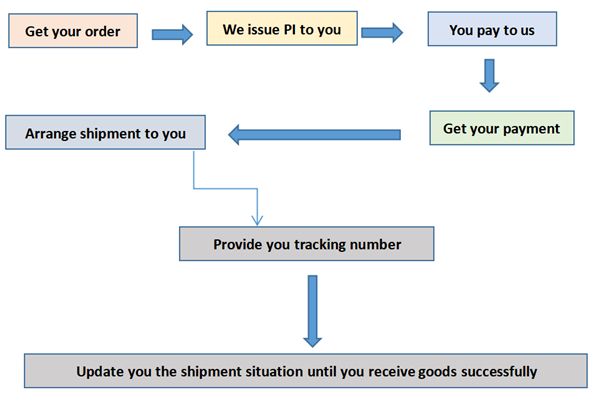

Order Steps

SHENZHEN CHAOYI MACHINE CO.,LTD

SHENZHEN CHAOYI MACHINE CO.,LTD