Electric waste stripper high power electric waste remover

Technical Details

|

Item Number |

EL-13 |

|

Type |

Electrical stripper |

|

Color |

BLUE |

|

Revolution |

3800 turns /min |

|

Chain |

#2 with 18 cogs (large size) |

|

Working power |

1400W |

|

Power supply |

220v~250v |

|

Net weight |

5.5 KG |

|

Minimum cutting size |

5MM |

|

Suitable paper |

all kinds of paper. Efficiency will be higher for kraft paper / corrugating medium paper |

|

Gross Weight |

6.5KG |

|

Package Dimensions |

490*170*240mm |

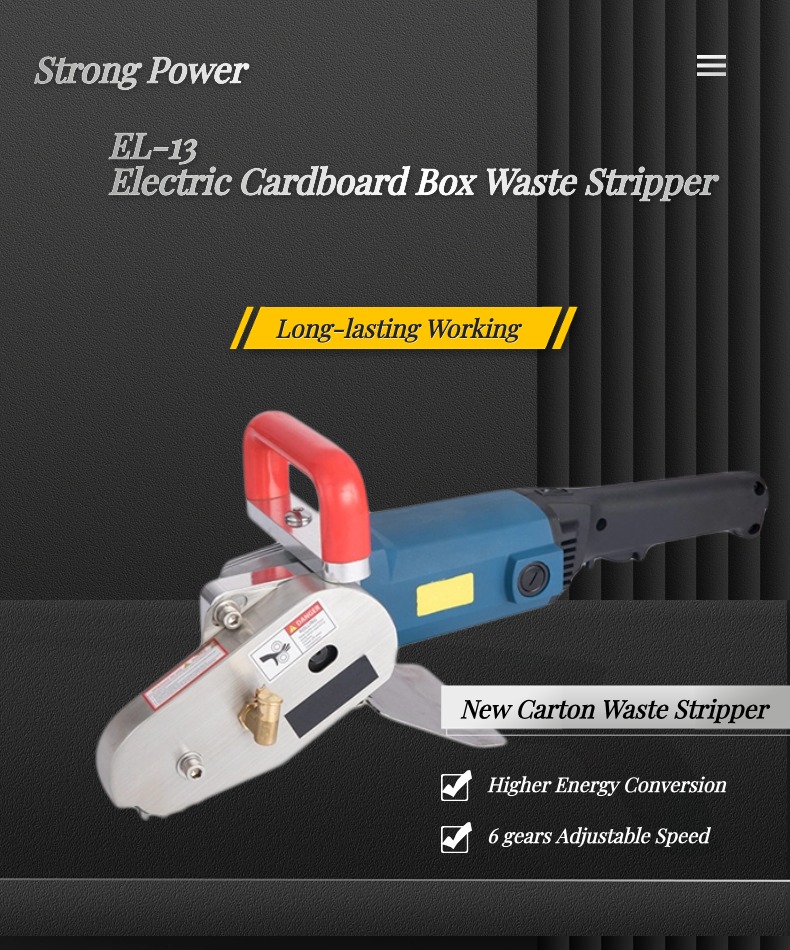

EL-13 High-Speed Electric Waste Stripper for Paper Carton Board

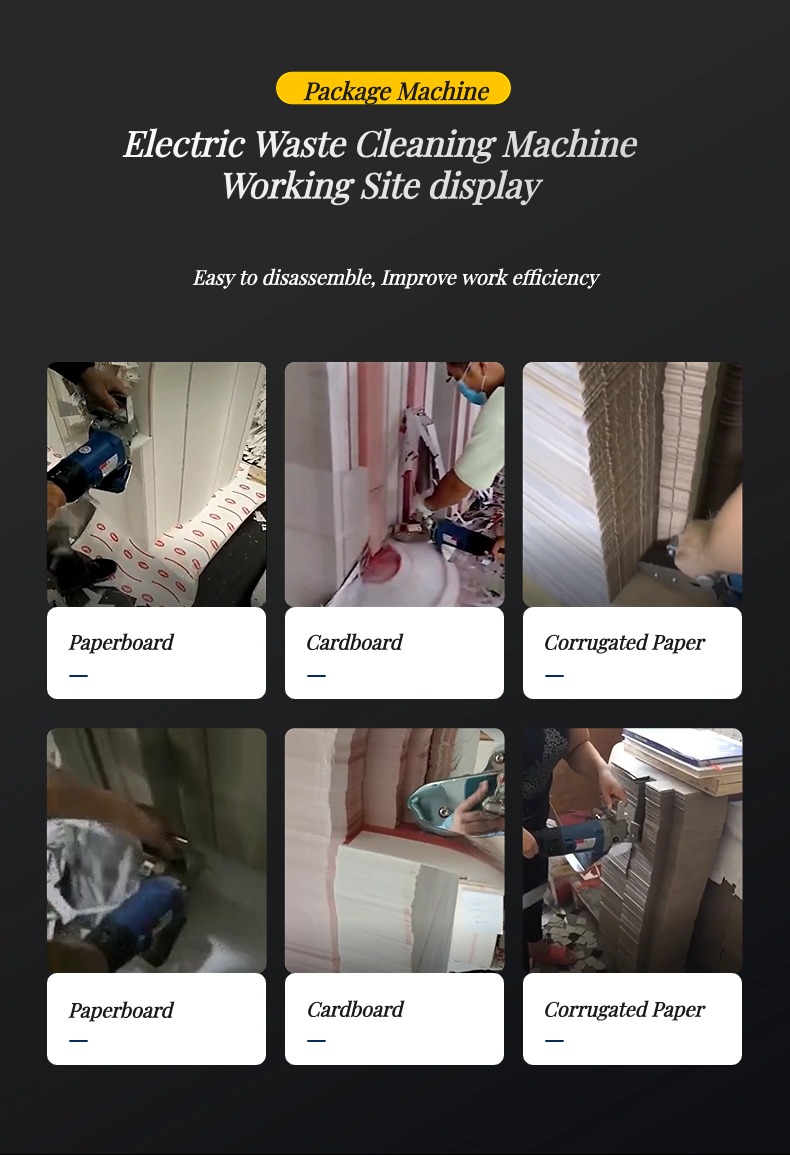

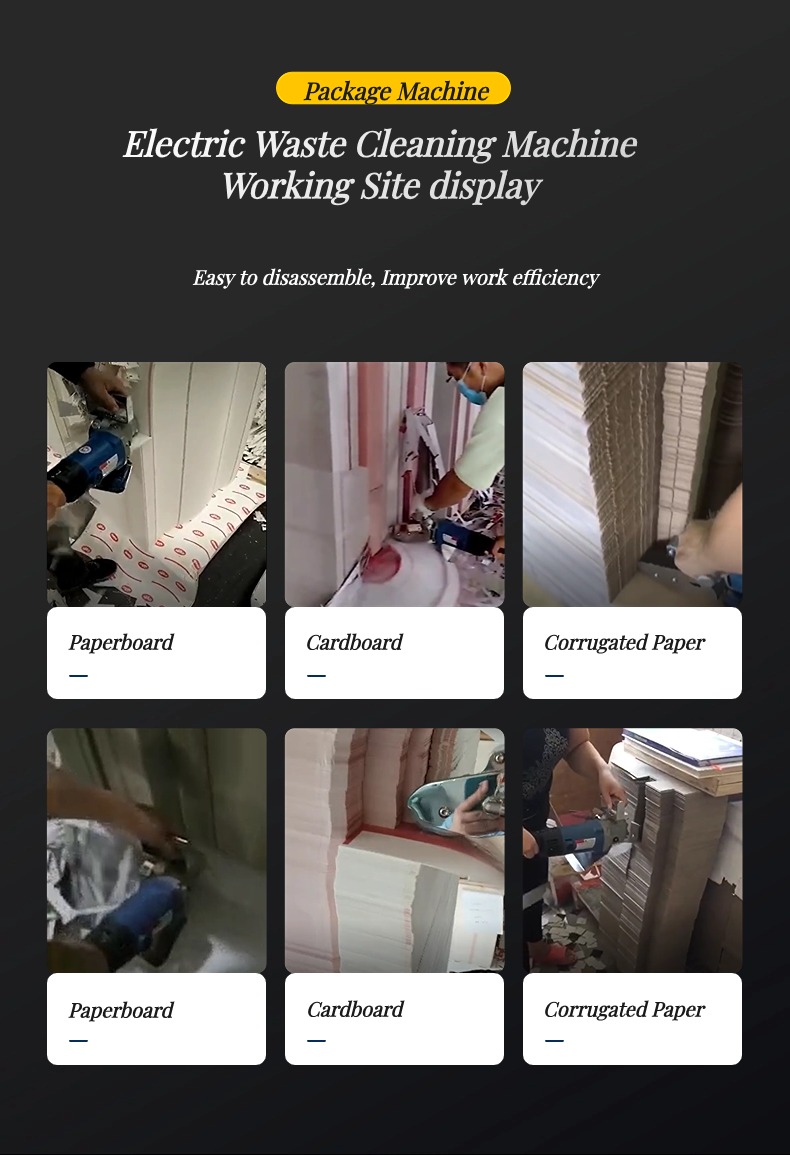

Designed for the efficient removal of waste margins from cardboard, thin corrugated paper, and common corrugated paper in the printing industry.

While manual stripping typically takes hours, the stripping machine can complete the task in 10 to 30 minutes, improving stripping efficiency by nearly 10 times and significantly shortening the delivery cycle.

Ensures no damage to the bonding area during stripping, thereby enhancing efficiency.

Compact configuration, with a weight similar to that of a portable polishing machine, making it easy to use. After simple training, both men and women can operate the machine.

Reduces the occurrence of industrial injuries, such as wrist, back, shoulder injuries, and repetitive motion-related injuries.

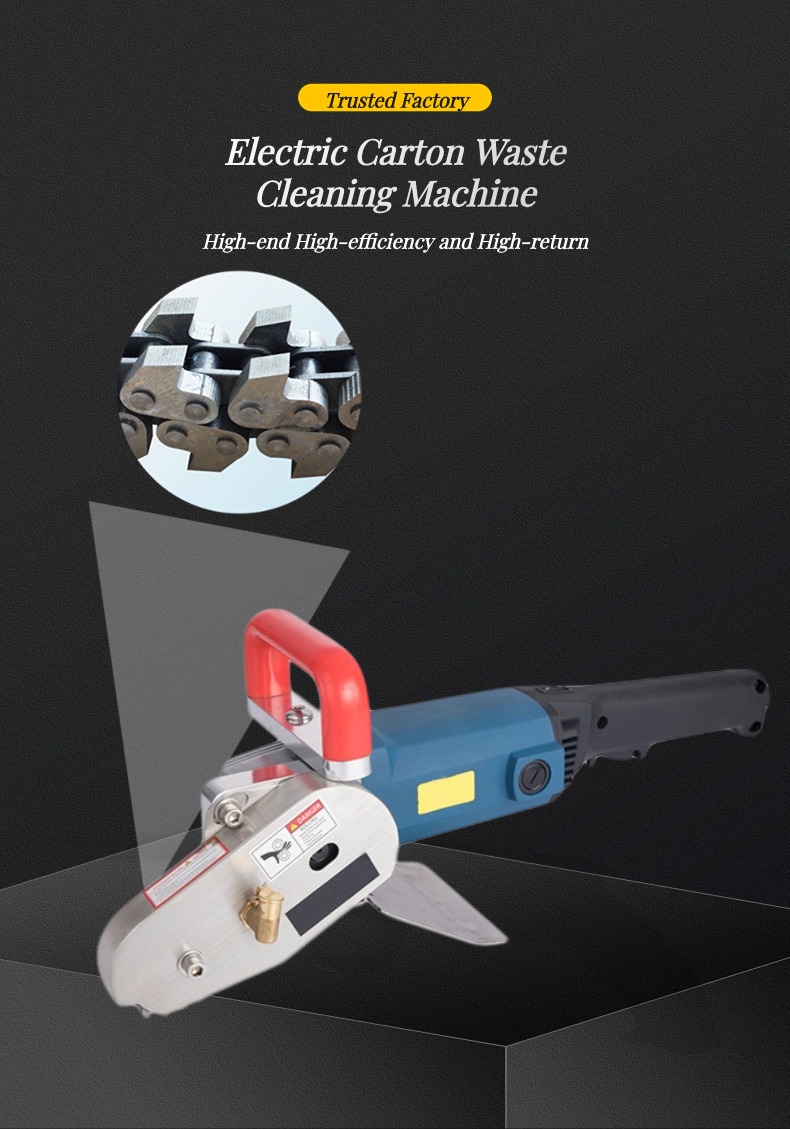

The tooth chain is made of high-strength alloy steel following a heat treatment process, resulting in high hardness, wear resistance, long lifespan, and easy replacement.

Advantages of EL-13 Electric Waste Stripper Compared to Pneumatic Strippers

Convenience: Easily change positions without the need for fixed air compressor positioning. It can be used anywhere with a simple connection to a 220V~250V power supply.

Low maintenance: As it is powered and not susceptible to water vapor ingress, maintenance requirements are minimal.

Adjustable speed: The machine offers 6 gears for speed adjustment, making it easy and simple to operate at the desired speed.

How to Use It

Turn on the switch to start the machine and adjust the speed as needed.

Neatly stack the cardboard papers requiring waste removal, ensuring that all four sides are flat.

The four sides of the cardboard must have cutting edges, and the distance between the cutting edges should match the cardboard stacking position. Arrange an appropriate gap on the cutting edges to ensure that the waste part connects with the products. The waste corner to be stripped must be ≥ 8mm to facilitate easy breakpoint creation.

After use, turn off the switch.

The electrical waste stripper is a precision tool, and its maintenance is more important than repairs. Detailed instructions for use will be provided upon delivery.

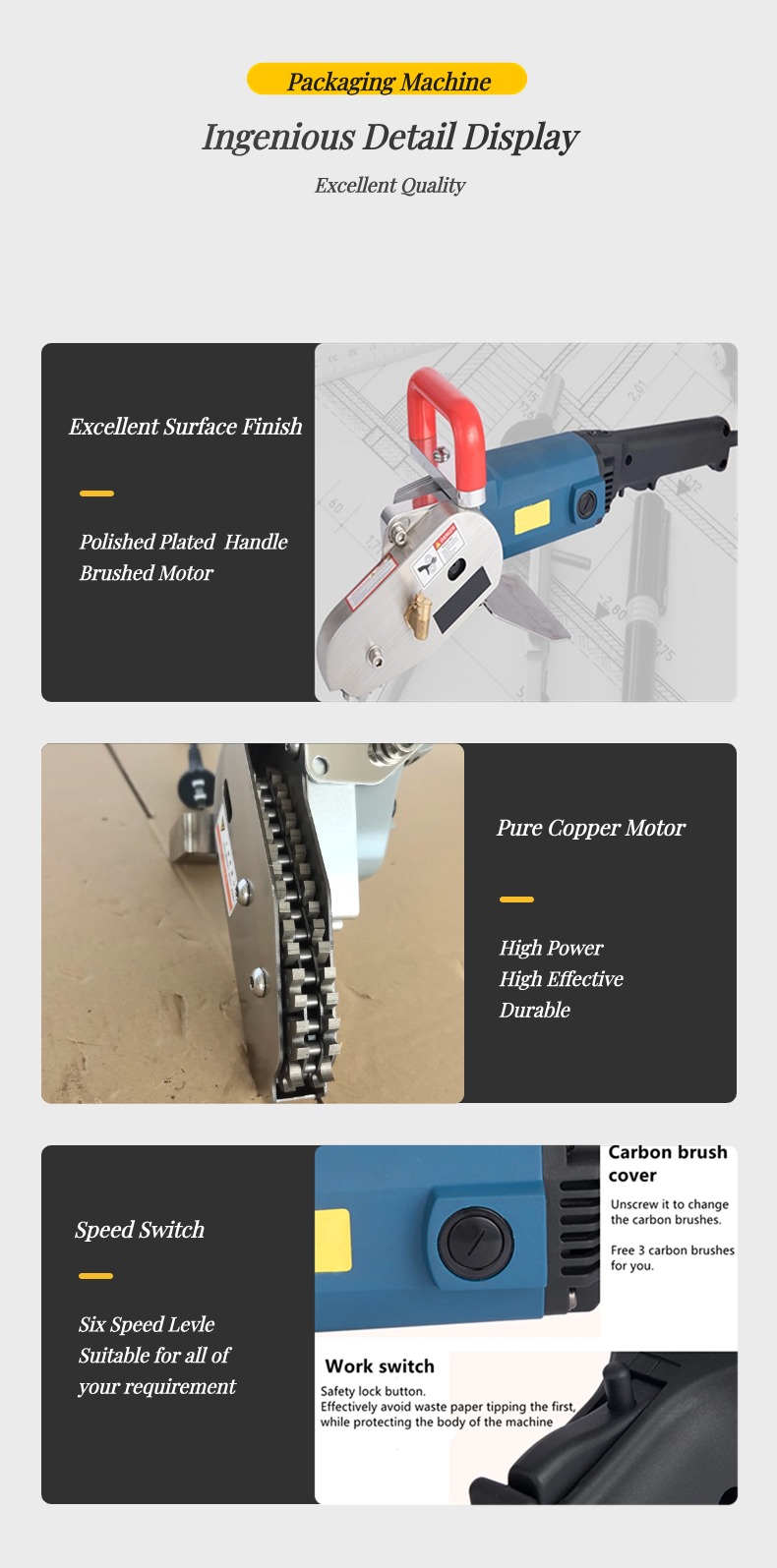

EL-13 ELECTRICAL WASTE STRIPPER PICTURES DISPLAY

EL-13 High Power Electric Waste Remover:

The EL-13 electric carton waste remover is a state-of-the-art upgrade from the standard carton waste stripper, delivering a robust power output of 1400W and offering six adjustable speeds for versatile operation.

Operating at 220V, this machine is equipped with a 2.6m extended power line and a two-pin plug, ensuring effortless setup and convenience.

This electric carton waste stripper effectively resolves the challenge of removing waste edges in printing processing facilities without the need for an air compressor, providing a more efficient and streamlined workflow.

The Chaoyi brand electric waste remover is distinguished by its pure copper motor, enhanced coil, and exceptional motor stability, ensuring reliable and consistent performance.

Additionally, the main control board of the Chaoyi electric waste remover is fortified with over-current, over-voltage, and over-temperature protection mechanisms, guaranteeing safe and secure operation.

Constructed from high-quality ABS and stainless steel alloy materials, this machine adheres to stringent safety production standards, ensuring durability and reliability in industrial settings.

Operation Manual of Electric Waste Remover:

Please operate the machine with both hands to ensure a clean and orderly connection plug and usage environment.

When using the electric carton waste stripper, operate for 30 minutes, then allow for a 1-minute rest period to take advantage of the machine’s effective heat dissipation and provide the operator with corresponding rest time.

Prior to each day’s operation, lubricate the chain and gears, and clean the machine’s surface.

Ensure that there is no paper or debris obstructing the air suction and exhaust holes on the body and motor to maintain unobstructed airflow and heat dissipation channels.

When using the carton waste stripper, ensure that the cutter die is configured to effectively separate the waste edges, ensuring optimal waste cleaning performance.

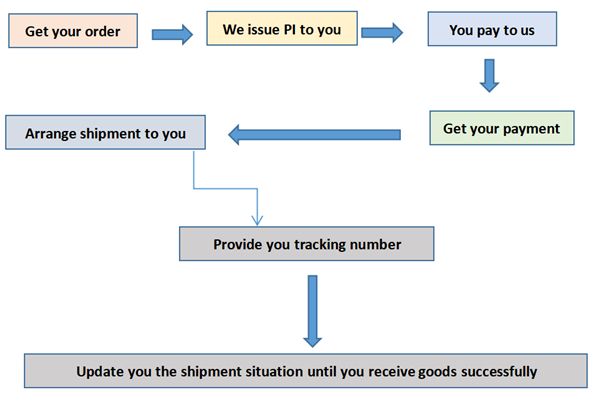

ORDER PROCESS

SHENZHEN CHAOYI MACHINE CO.,LTD

SHENZHEN CHAOYI MACHINE CO.,LTD