CY-800 Semi-automatic Diecut inner hole waste stripping tool

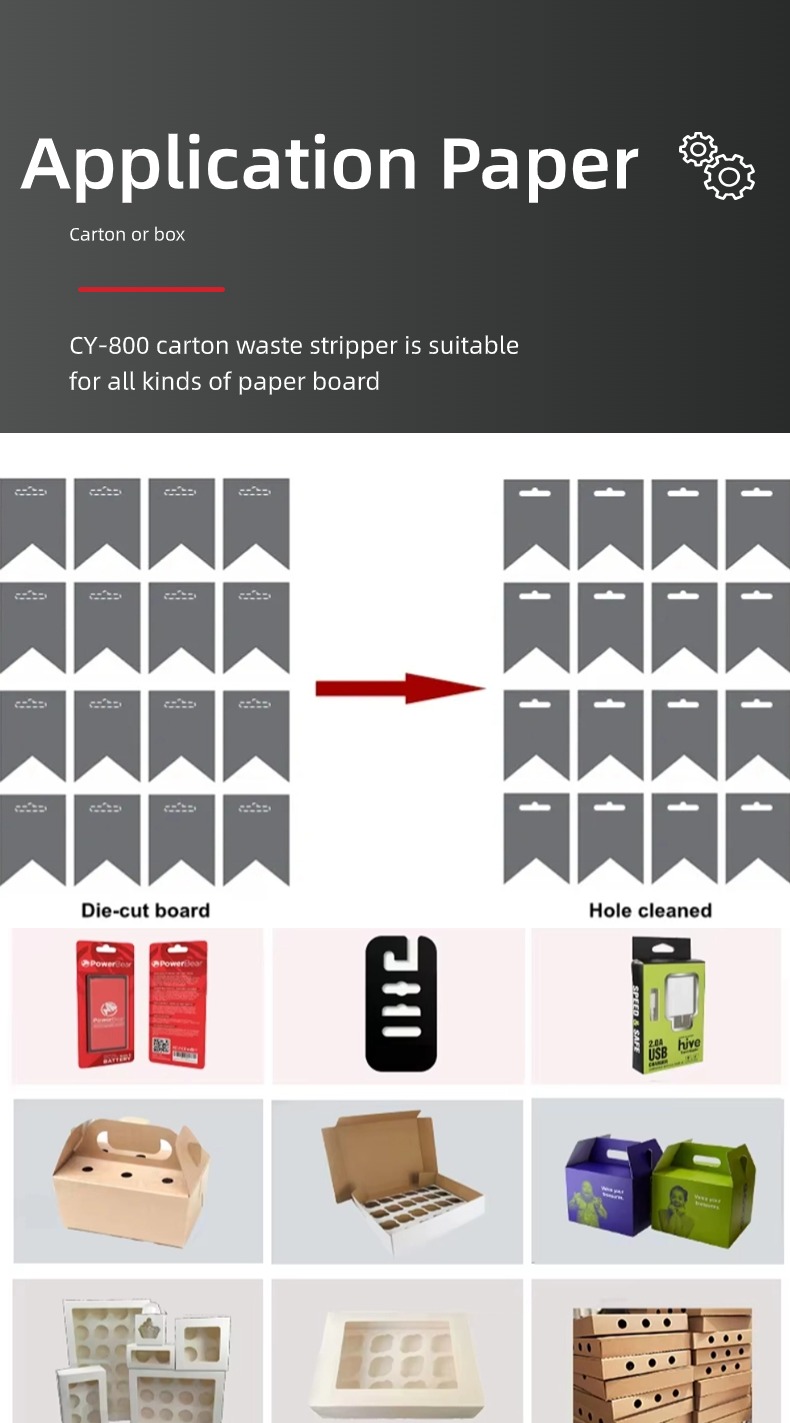

This machine is primarily designed for color printing and packaging companies to remove waste paper from various types of color boxes and cartons after die-cutting the inner holes (such as round, square, elongated, airplane-shaped, and custom shapes). It is suitable for hangtags, cartons, and color boxes, allowing for the clearing of one or multiple holes.

Features

High precision and user-friendly operation.

Customizable molds allow for adjustable punching dies, enabling the installation of multiple molds simultaneously to efficiently clear dozens of waste holes. Multiple holes can be processed at once, enhancing work efficiency.

The punching die applies pressure to the product without compromising its integrity.

A built-in cleaning box can be included.

Pneumatic Inner Hole Waste Stripping Machine

This machine is primarily utilized by color printing and packaging companies for the removal of waste paper from various color boxes and cartons after die-cutting the inner holes (including round, square, elongated, airplane-shaped, and custom shapes). It is suitable for hangtags, cartons, and color boxes, allowing for the clearing of one or multiple holes simultaneously.

The semi-automatic stripping hole cleaning machine features several key components designed for optimal performance and ease of use. Its adjustable locking plate can accommodate multiple molds at once, enabling the efficient cleanup of numerous waste holes, significantly reducing labor requirements and enhancing work efficiency.

Product Description

The CY-800 is a pneumatic stripping machine designed to eliminate excess material from various substrates, including paper, corrugated cardboard, foil, plastic, foam, and rubber. It is versatile, accommodating different types and shapes of stripping tools and separation plates, with precise vertical guidance for the stripping plate. The table includes movable stops to help position the material being processed.

Moreover, it serves as a semi-automatic waste and inner hole removal machine, specifically engineered to clear waste from color box tag aircraft holes. This machine is primarily used in color printing and packaging enterprises to clean waste paper from inner holes after die-cutting various color boxes and cartons, including plane holes, round holes, square holes, elongated holes, and irregular shapes.

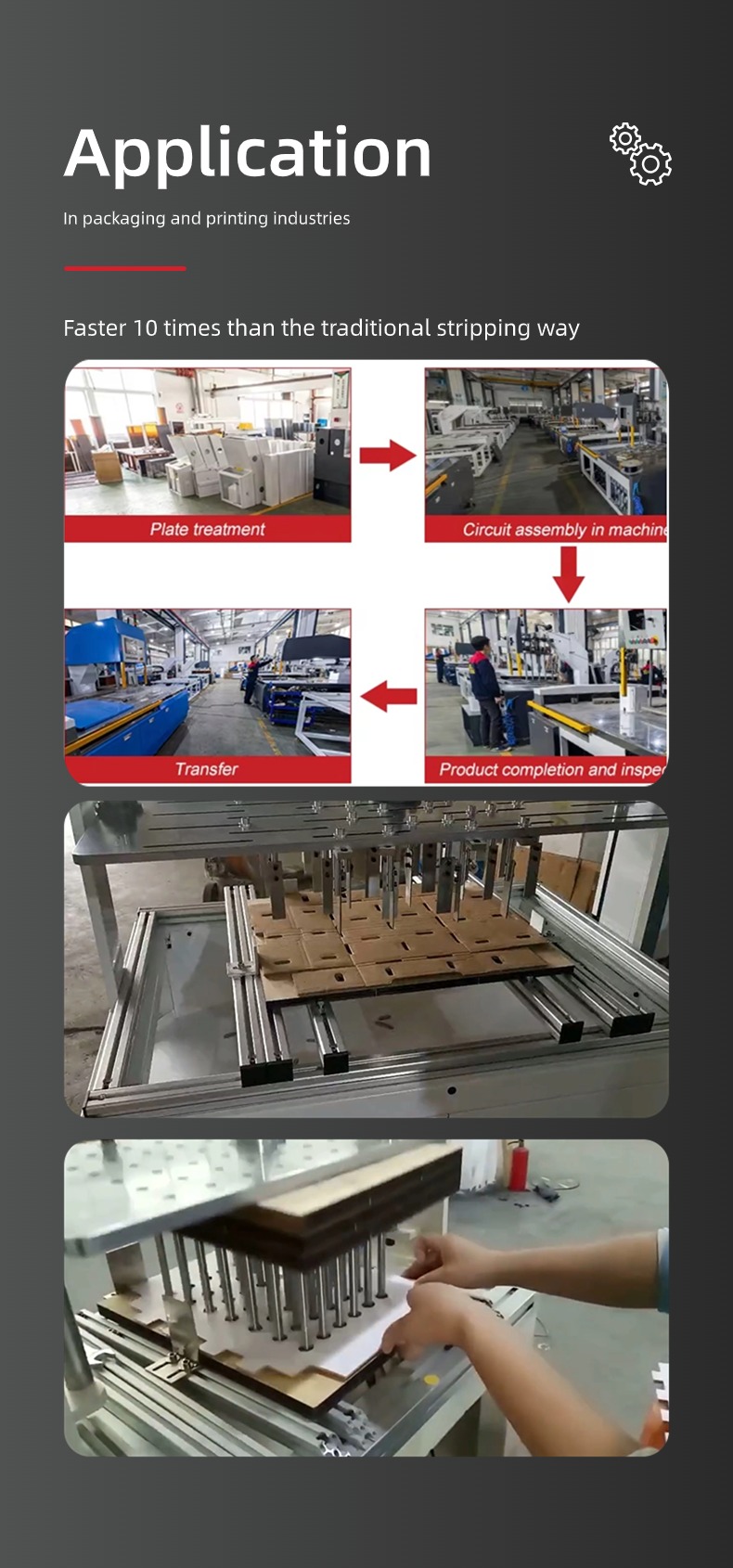

The machine’s essential components are meticulously designed and manufactured to ensure mechanical precision and ease of use. The adjustable locking plate can hold multiple molds at once, allowing for the simultaneous clearance of numerous waste holes, which significantly reduces labor requirements and enhances work efficiency.

The semi-automatic waste cleaning machine provides several advantages:

Decreases manual waste removal and labor costs

Reduces product losses and improves product quality

Boosts actual production efficiency by 30% to 50%

Facilitates efficient waste removal for products with multiple holes, unlike traditional manual methods

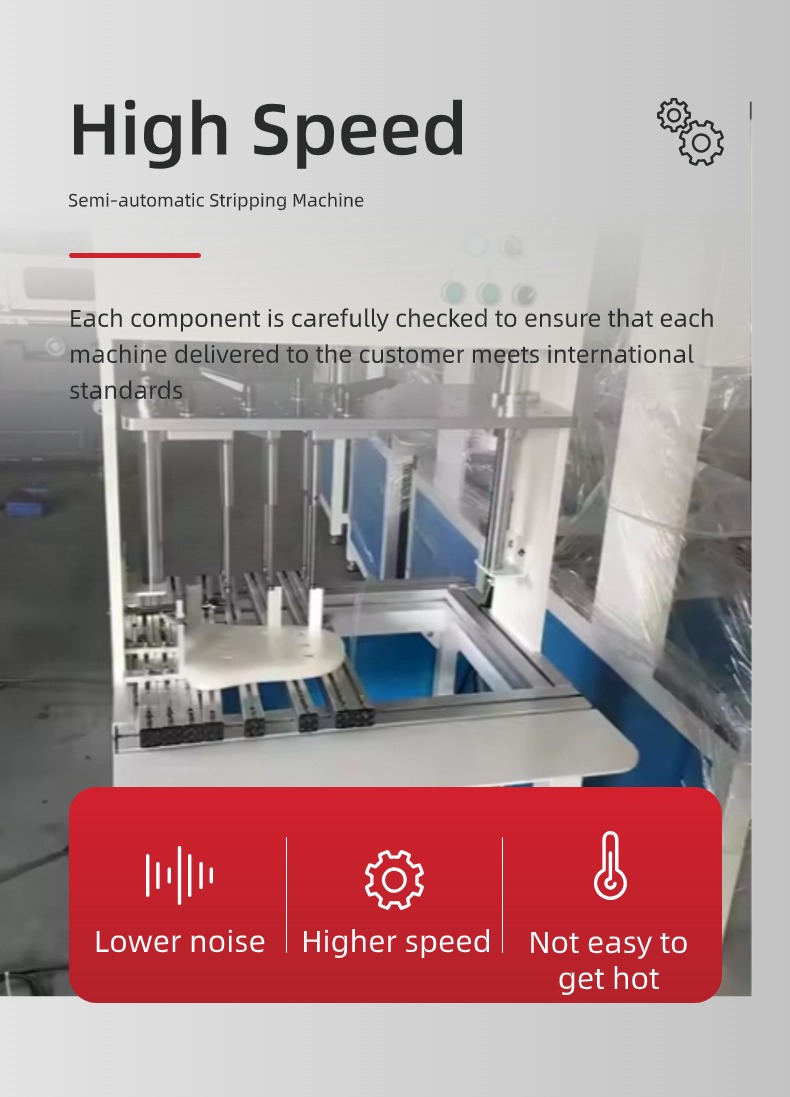

The semi-automatic inner hole waste removal machine features a compact design, straightforward operation, and a user-friendly interface, requiring only basic training for operators of any gender.

The machine is easy to set up, safe, and user-friendly.

Activation is controlled by a foot pedal, complemented by active safety light barriers.

The operation is user-friendly, with all functions managed through the control panel.

A visual indicator shows the status of the device.

Processed materials are loaded manually.

Quick adjustments can be made to accommodate new production needs.

Waste can be conveniently disposed of into a designated container.

The machine can utilize either universal or specialized stripping tools and plates.

Materials are held gently before the press movement, eliminating the need for manual support.

Ideal for smaller tasks due to its rapid changeover time.

A safety optical barrier prevents unauthorized activation of the machine by the operator.

Service access is available from the rear of the machine.

CY-800 Photos Show

Why choose us?

Infrared Safety Detection Sensor

The sensor prevents the machine from pressing down if the hand is not removed from the working desk, ensuring production safety.

Large Size Double Magnetic Ring Cylinder

The adoption of the 125-type cylinder ensures stable machine operation and smoother waste paper removal.

Foot Switch

The high-grade foot switch enables automatic waste cleaning, featuring a metal anti-misstep housing.

Additional Working Desk

Expanding the material preparation table provides space to set aside the product, increasing the product drag and drop length for more convenient waste clearance.

CY-800 Advantages

Minimize manual waste removal.

Reduce labor costs associated with product damage.

Achieve 40%-60% higher production efficiency.

Higher efficiency for products with multiple holes, as it can be completed in one go, unlike manual waste stripping. Special molds and needles are available upon request.

Compact design, user-friendly operation, suitable for both male and female operators after basic training.

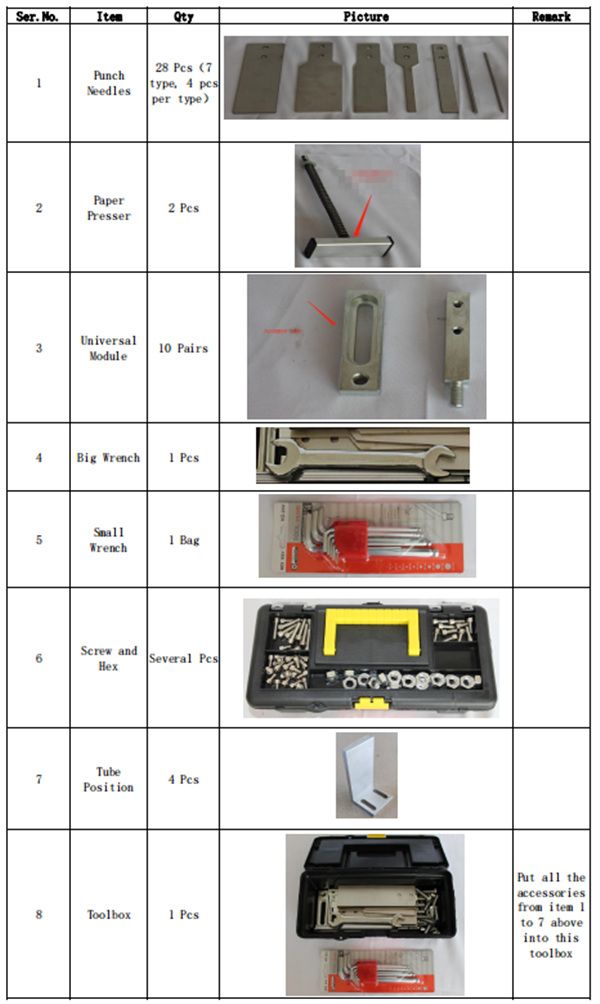

Accessory List

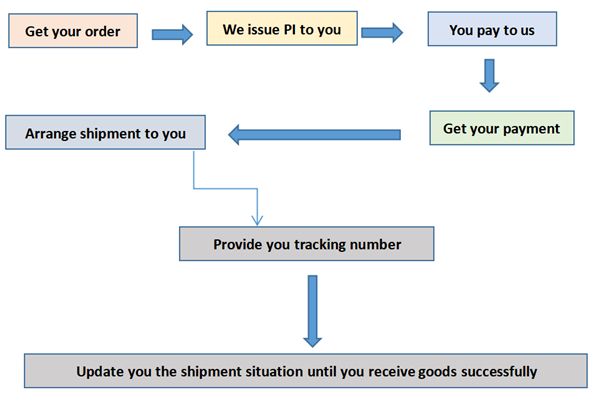

Order Steps

SHENZHEN CHAOYI MACHINE CO.,LTD

SHENZHEN CHAOYI MACHINE CO.,LTD