Inner Hole Waste Removal and Stripping Machine

**Technical Information**

1. **Reduce Manual Waste**:

This machine significantly minimizes the need for manual intervention in waste removal. By automating the process, it reduces human errors and inefficiencies that are often associated with manual stripping, ensuring that waste is consistently removed in a precise, efficient manner.

2. **Minimize Product Damage**:

The machine is designed to prevent damage to the product during the waste removal process. Unlike manual waste stripping, where handling and pressure can sometimes lead to product deformation or tearing, the machine uses specialized components to clean the holes without compromising the integrity of the product. This results in a higher-quality output with fewer defective items.

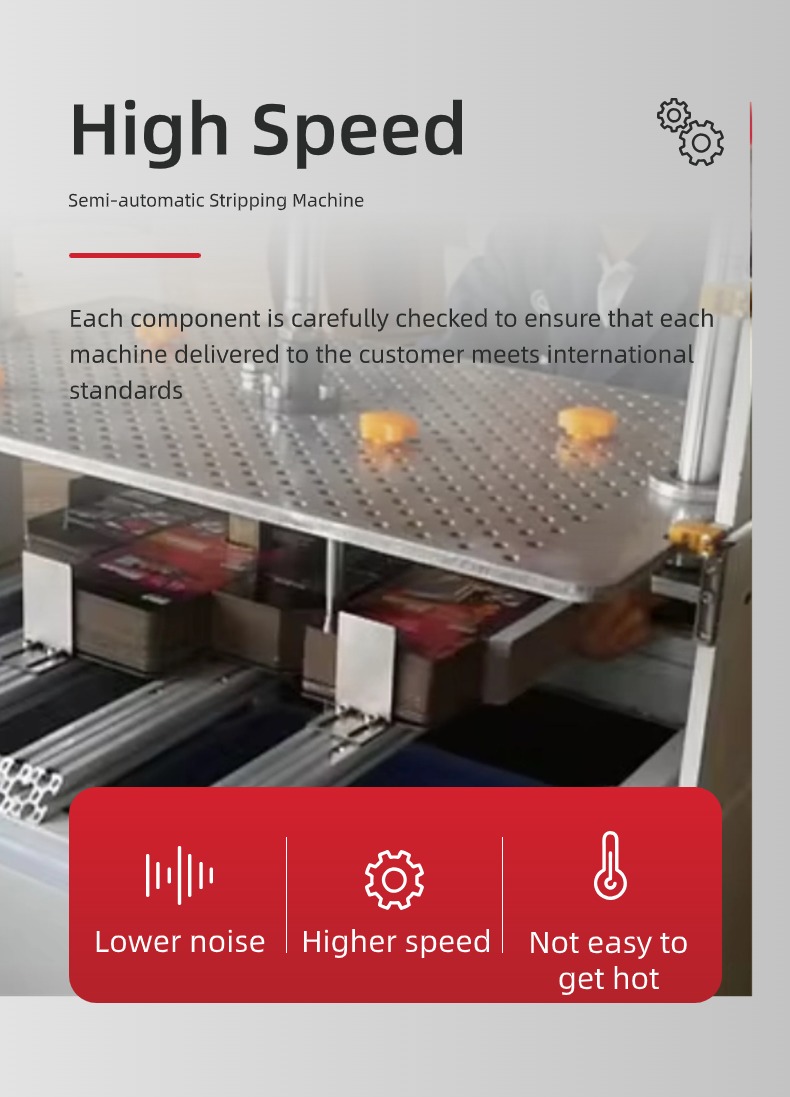

3. **Increase Production Efficiency by 30%-50%**:

The machine’s automated operation significantly boosts production efficiency. It achieves up to a 50% increase in output compared to traditional manual methods, allowing businesses to process a higher volume of products in less time. This not only enhances throughput but also improves the overall workflow on the production line.

4. **Higher Efficiency with More Holes**:

The machine is highly efficient when dealing with products featuring multiple holes. The more holes there are to clean, the higher the efficiency, as it can handle the removal of multiple waste holes in one cycle. This is a major improvement over manual stripping, where each hole would typically require individual attention, thereby increasing time and labor costs. Additionally, the machine offers customizable molds and needles based on specific production needs, further improving its versatility and efficiency.

5. **Compact and User-Friendly**:

Designed with a compact configuration, the machine is easy to operate and doesn’t require specialized technical skills. Both male and female operators can use it effectively after receiving basic training, making it an ideal solution for businesses with diverse teams. The user-friendly interface and straightforward controls ensure that the machine can be integrated smoothly into any production environment, saving both time and training costs.

Overall, this machine offers a combination of efficiency, precision, and ease of use, providing businesses with a reliable tool to streamline their waste removal processes while improving productivity and product quality.

|

SPECIFICATIONS FOR Inner Hole Waste Stripping Machine |

||

|

Model Number |

CY-720 |

CY-920 |

|

Machine Size |

1000*720*1580mm |

1300*920*1580mm |

|

Working surface size |

1000*720mm |

1300*920mm |

|

Orifice board size |

900*600mm |

1200*800mm |

|

Air pressure |

0.8BAR |

0.8BAR |

|

Pressure |

1.5T |

2T |

|

Route |

150mm |

150mm |

|

Net Weight |

500kg |

600kg |

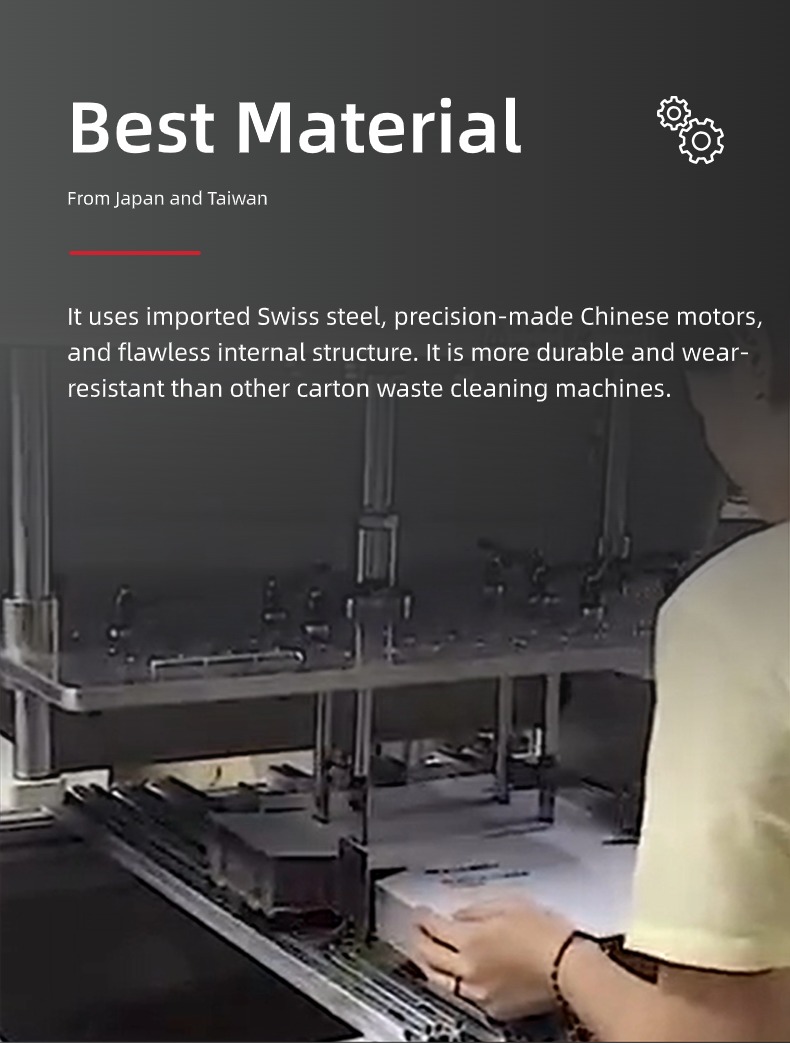

**Pneumatic Inner Hole Waste Stripping Machine: Efficient Waste Removal for Color Printing and Packaging**

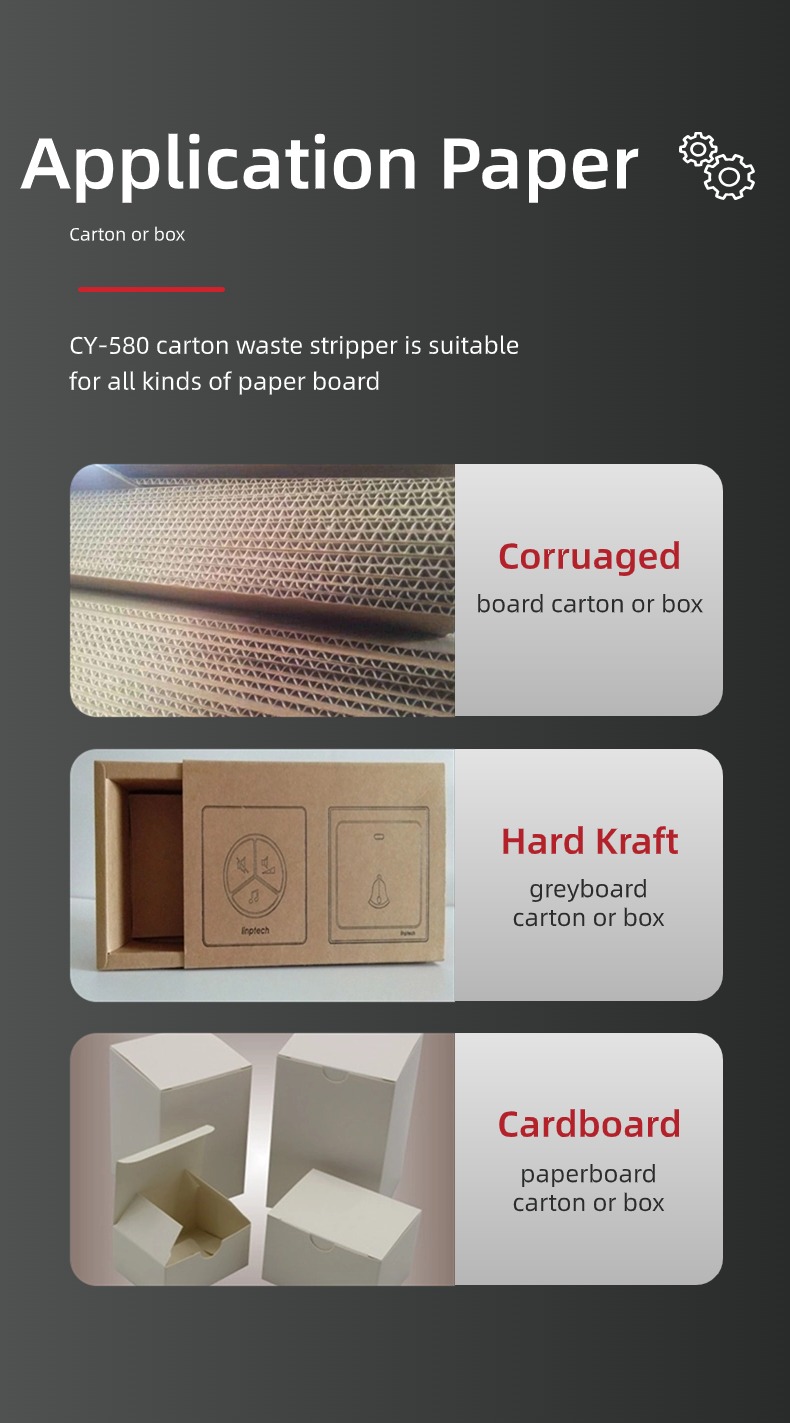

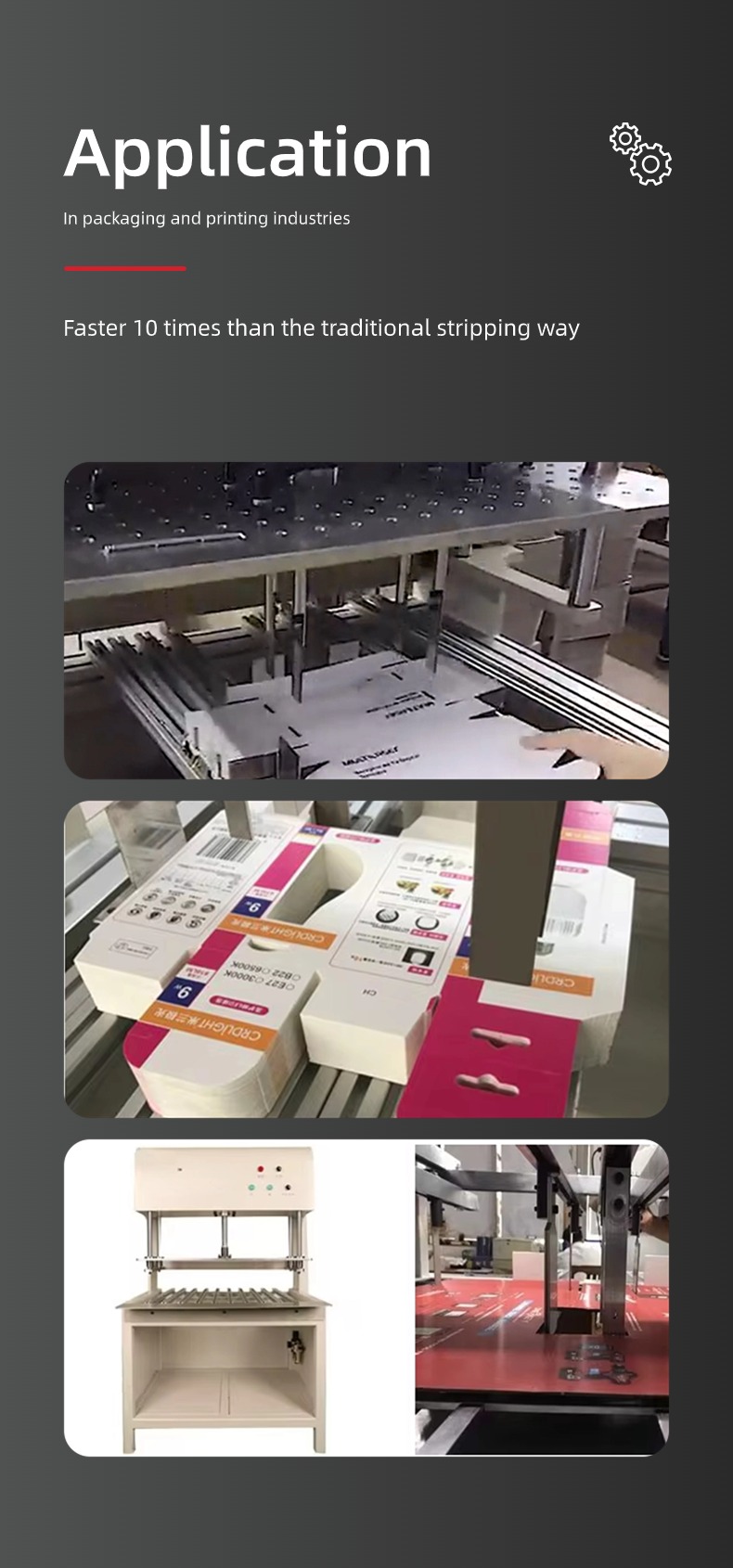

The **Pneumatic Inner Hole Waste Stripping Machine** is designed primarily for the color printing and packaging industry, where it plays a vital role in cleaning up the residual waste after the die-cutting process. This machine efficiently removes waste paper from various hole shapes left behind in products like color boxes, cartons, hangtags, and more. Whether the holes are round, square, rectangular, airplane-shaped, or irregular, this machine ensures thorough waste removal, making it an indispensable tool for businesses in the packaging industry.

**Key Features:**

1. **High Precision and Easy Operation**:

The machine is engineered to deliver high accuracy during the waste removal process. It operates smoothly, ensuring that the integrity of the product remains intact while removing the waste efficiently. The user-friendly design ensures that operators can quickly learn to operate the machine, reducing training time and minimizing errors.

2. **Customizable Molds for Enhanced Flexibility**:

One of the standout features of this machine is its ability to handle various mold sizes and configurations. The mold can be adjusted, and multiple punching dies can be added or removed depending on the production requirements. This flexibility allows the machine to process multiple holes simultaneously, which significantly increases work efficiency. This feature is especially beneficial for high-volume production environments, where speed and accuracy are essential.

3. **Gentle, Non-Destructive Punching**:

The punching die generates just the right amount of pressure on the material to remove the waste without causing any damage to the product itself. This ensures that the final product remains intact and free from any deformation, which could otherwise lead to quality issues or product rejection.

4. **Built-In Cleaning Box for Waste Collection**:

The machine comes equipped with an integrated cleaning box that collects all the waste materials produced during the stripping process. This feature reduces mess, streamlines waste management, and makes disposal easier. The built-in box ensures that the production environment remains clean and organized.

**Product Description:**

The **CY-720 Pneumatic Stripping Machine** is a powerful and versatile solution designed to handle a variety of materials, including paper, corrugated cardboard, plastic, foam, and rubber. The machine is equipped with an adjustable stripping plate that moves with precise vertical guidance to ensure accurate waste removal. It can be customized with different stripping tools and separation plates to accommodate a wide range of products and production needs.

As a **semi-automatic waste and inner hole removal machine**, the CY-720 is particularly effective in cleaning waste from inner holes (such as round, square, and irregular holes) after the die-cutting process. This is especially useful for cleaning waste from color boxes and cartons used in the packaging and printing industries. The machine’s precision ensures that even delicate or intricate designs are handled without damage.

The machine’s adjustable locking plate can accommodate multiple molds at once, enabling the removal of waste from dozens of holes simultaneously. This significantly reduces labor costs, as the machine can handle large volumes of work in a fraction of the time it would take to perform manually. The result is a dramatic increase in work efficiency and overall production speed.

**Benefits of the CY-720 Pneumatic Stripping Machine:**

- **Labor and Cost Savings**:

By reducing the need for manual waste removal, this machine drastically lowers labor costs. It also minimizes product loss, as the precise punching action ensures that the final product remains intact and free from damage.

- **Increased Production Efficiency**:

The CY-720 increases production efficiency by 30% to 50% compared to traditional manual methods. The machine is capable of handling large batches quickly, making it ideal for high-volume production lines.

- **Cleaner Production Process**:

Unlike traditional methods, where waste removal can be messy and inconsistent, the CY-720 offers a much cleaner and more efficient process. The built-in cleaning box and precise waste removal features ensure that waste is disposed of neatly, helping maintain a clean production environment.

- **Highly Adaptable for Various Hole Types**:

The machine is versatile and can handle products with a variety of hole shapes and sizes. Whether dealing with simple round holes or complex irregular shapes, the CY-720 offers reliable waste removal, providing excellent value for diverse production needs.

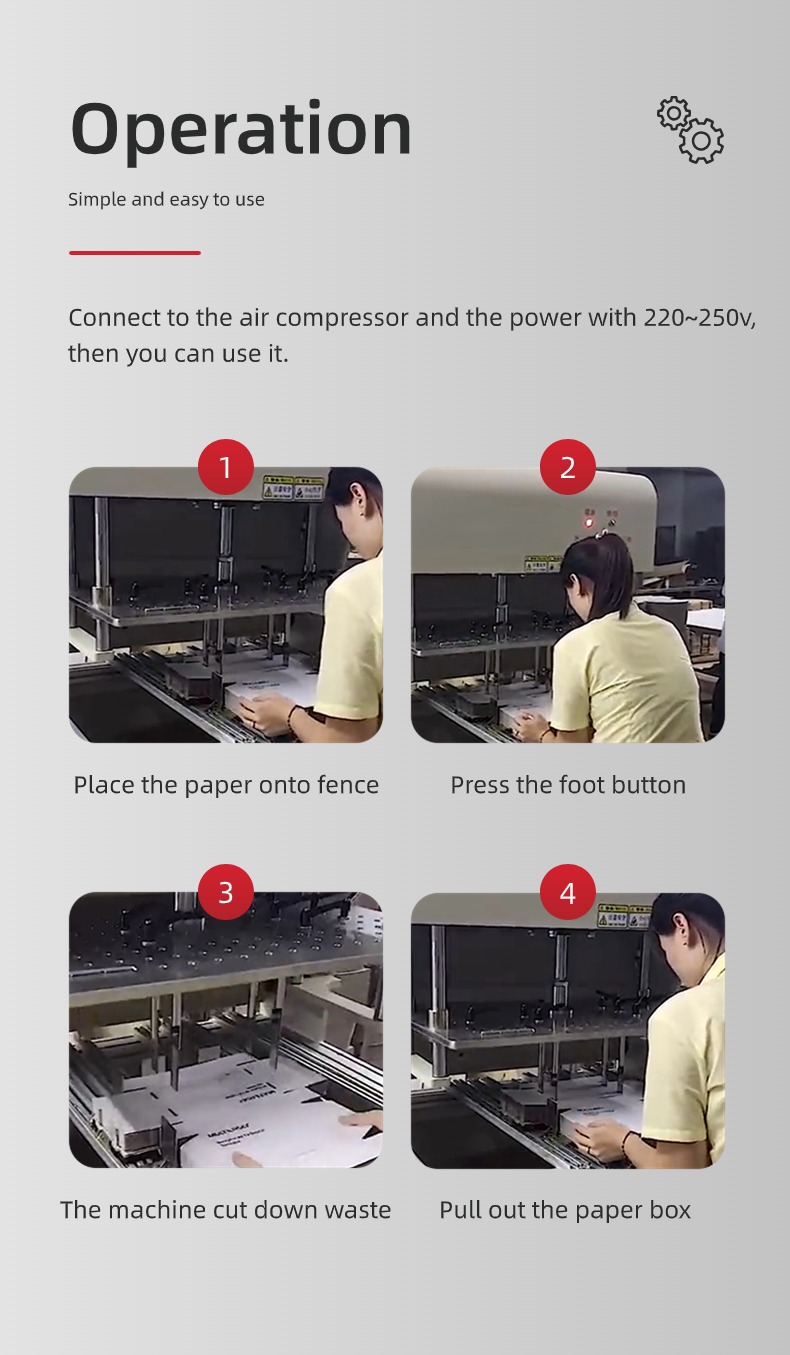

**User-Friendly Design and Safety Features:**

The CY-720 is designed for ease of use, ensuring that both male and female operators can operate the machine with minimal training. The simple controls and intuitive setup make it accessible even for workers with little technical experience.

- **Foot Pedal Activation**:

Activation is done via a foot pedal, with built-in safety light barriers that ensure safe operation. This feature prevents accidental activation, protecting operators and ensuring safe machine use.

- **Efficient Operation with Control Panel**:

All machine functions can be controlled via an easy-to-use control panel. A visual indicator on the panel displays the status of the machine, allowing operators to monitor its performance in real time.

- **Quick Setup and Adaptability**:

The CY-720 is designed for quick adjustments, making it easy to switch between different production requirements. Whether the operator needs to clean a batch with more holes or switch to a different product type, the machine can be quickly adapted without significant downtime.

- **Safety Optical Barrier**:

An optical barrier prevents unauthorized machine activation, ensuring that operators can work safely without risk of injury.

- **Convenient Waste Disposal**:

The waste material generated during the stripping process is conveniently collected in a waste container, making disposal simple and reducing downtime caused by cleaning.

**Conclusion:**

The **CY-720 Pneumatic Inner Hole Waste Stripping Machine** is a high-performance, user-friendly solution for the packaging and printing industries. By automating the waste removal process, it reduces labor costs, increases production efficiency, and improves product quality. Whether you are working with color boxes, hangtags, or cartons, this machine provides the precision and flexibility needed to streamline your production line and maintain high standards of cleanliness and quality.

CY-720 Photos Show

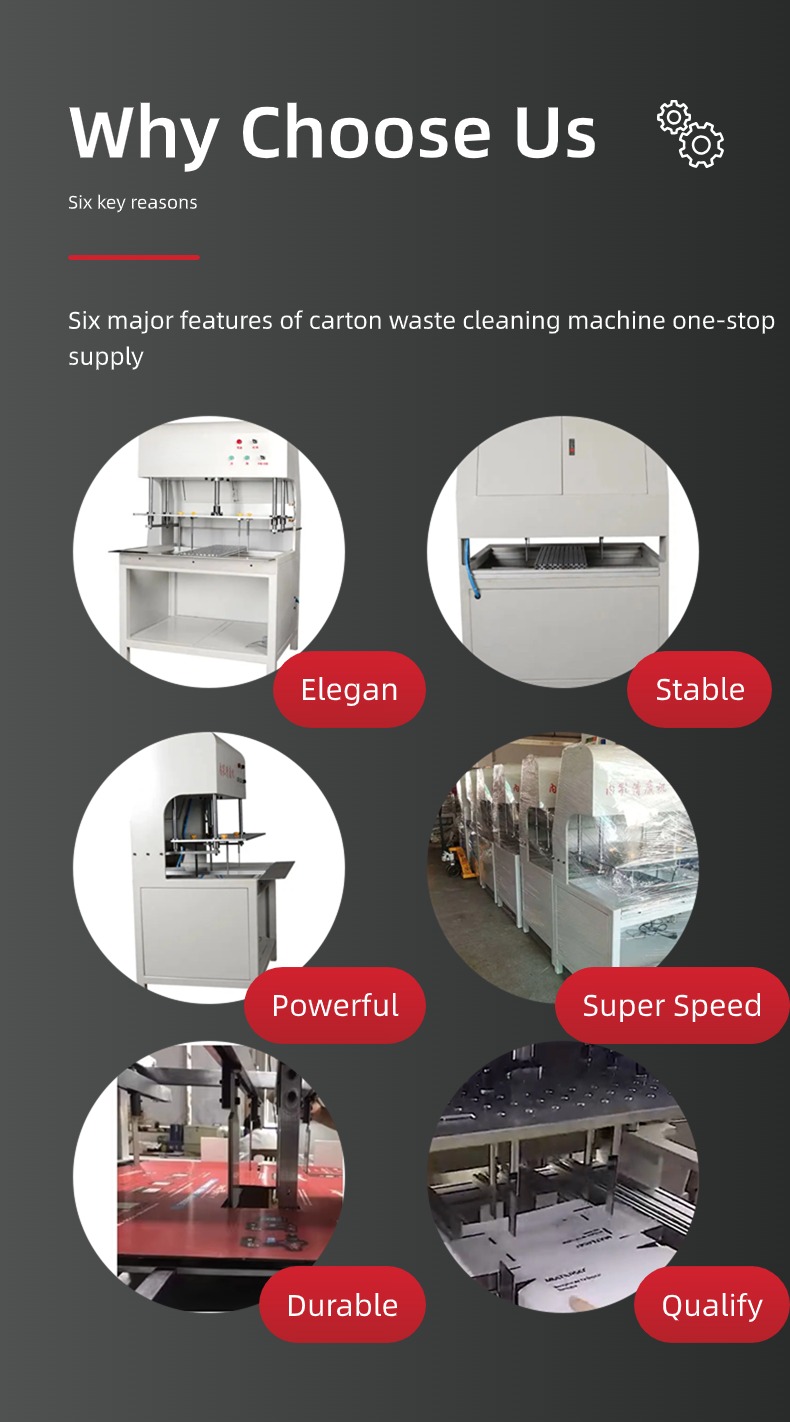

Why choose us?

Infrared Safety Detection Sensor

The sensor prevents the machine from pressing down if the hand is not removed from the working desk, ensuring production safety.

Large Size Double Magnetic Ring Cylinder

The adoption of the 125-type cylinder ensures stable machine operation and smoother waste paper removal.

Foot Switch

The high-grade foot switch enables automatic waste cleaning, featuring a metal anti-misstep housing.

Additional Working Desk

Expanding the material preparation table provides space to set aside the product, increasing the product drag and drop length for more convenient waste clearance.

CY-720 Advantages

Minimize manual waste removal.

Reduce labor costs associated with product damage.

Achieve 40%-60% higher production efficiency.

Higher efficiency for products with multiple holes, as it can be completed in one go, unlike manual waste stripping. Special molds and needles are available upon request.

Compact design, user-friendly operation, suitable for both male and female operators after basic training.

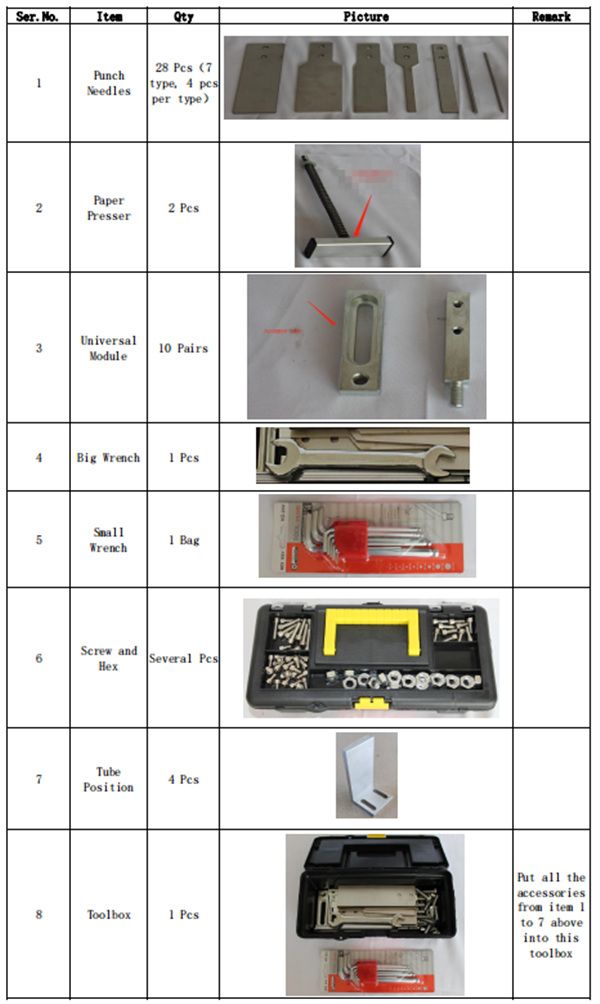

Accessory List

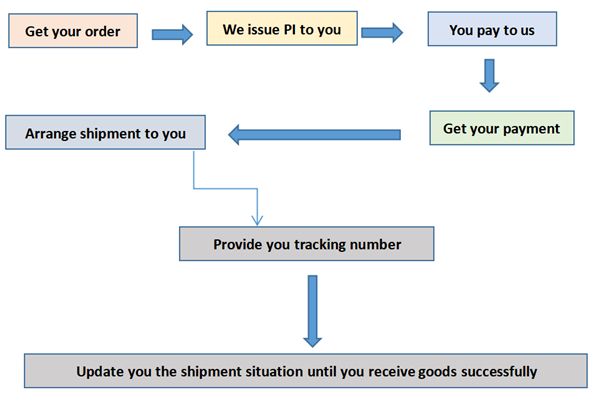

Order Steps

SHENZHEN CHAOYI MACHINE CO.,LTD

SHENZHEN CHAOYI MACHINE CO.,LTD