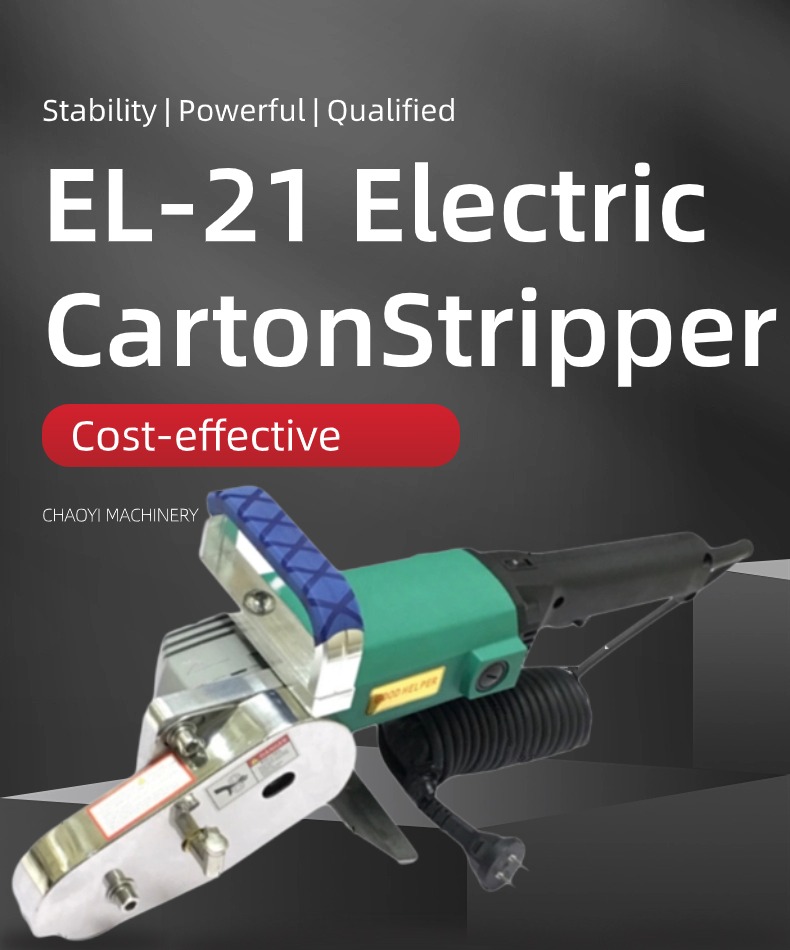

Electric Waste Stripping Machine for Corrugated Cartons

### **Precautions for Using the Electric Waste Stripper Machine EL-21:**

1. **Heat Dissipation:**

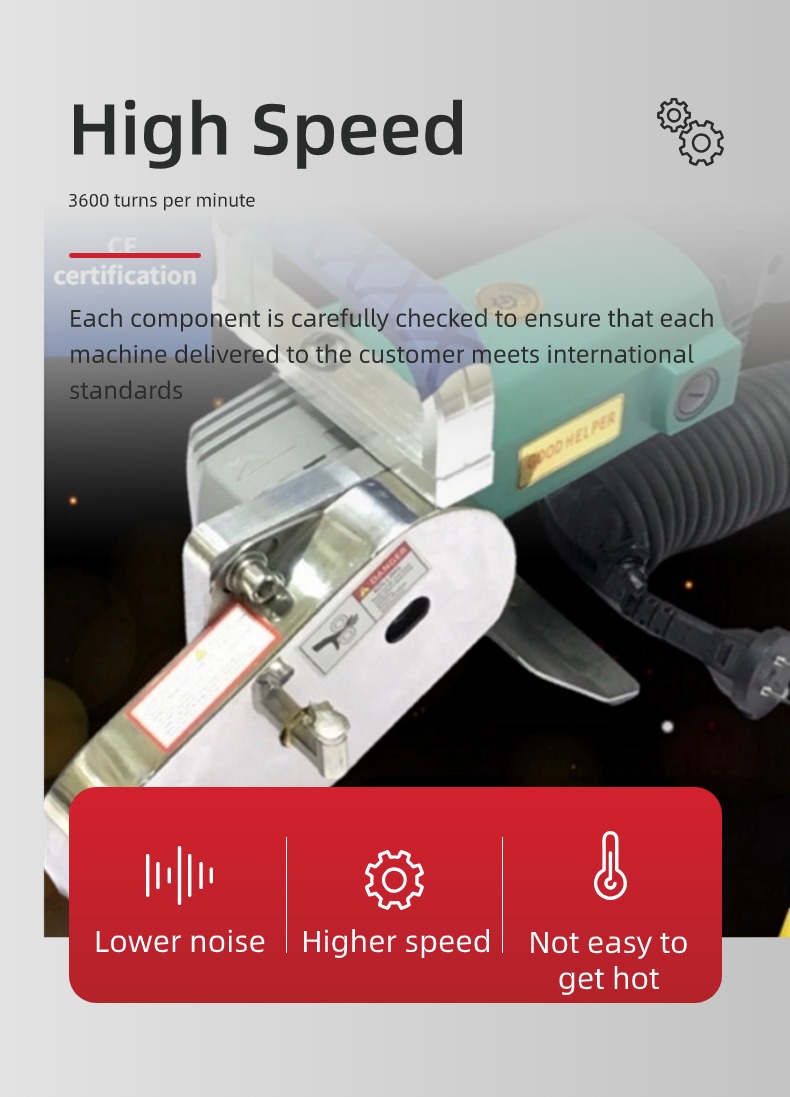

After 15 minutes of continuous operation, let the machine rest for 30 seconds to extend its lifespan.

2. **Gear Speed:**

For the 1400W electric scraper, use gears 1-4 for optimal performance. Avoid using gears 5 and 6.

3. **Machine Cleaning:**

Blow out paper scraps from the machine with an air gun daily to prevent overheating and ensure longevity.

4. **Paper Jam:**

If the machine jams, unplug it, clear the paper, and restart. Avoid starting the machine while paper is stuck to prevent internal damage.

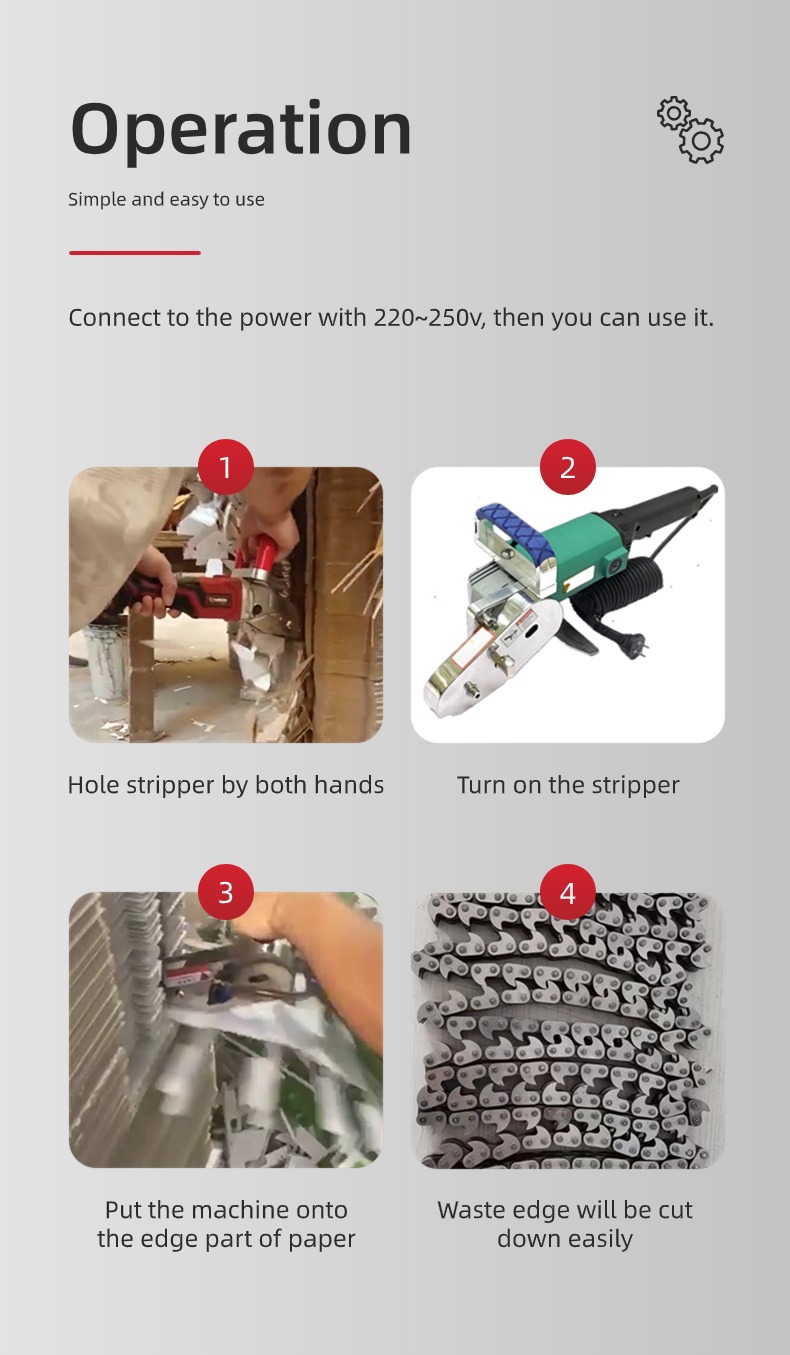

5. **Voltage Requirements:**

Use 220V two-phase electricity with a 2.6m standard cable.

6. **Waste Removal Process:**

Use both hands to lightly press and remove the waste. Do not use a hammer.

7. **Safety Precautions:**

- Operate with both hands to avoid injury from the chain.

- Do not lift the base plate or use hard objects near the chain to prevent damage.

8. **Rest Time:**

After 15 minutes of use, let the machine rest for 30 seconds.

9. **Lubrication:**

Apply engine oil to the chain-gear connection regularly and run the machine idle for 1 minute.

10. **Motor Maintenance:**

Replace the carbon brush when motor power decreases.

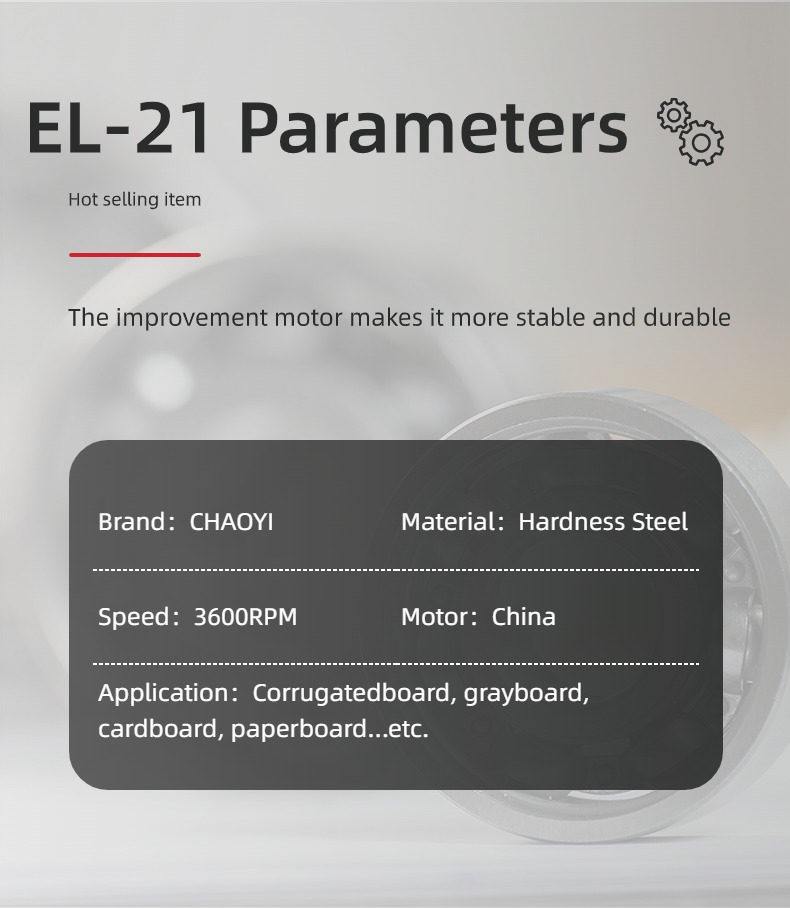

### **About the Die Cutting Waste Stripper EL-21:**

Die cutting waste strippers are essential tools for efficiently removing excess material from die-cut products. They enhance production by ensuring clean, precise waste removal, which improves the quality and appearance of the final product.

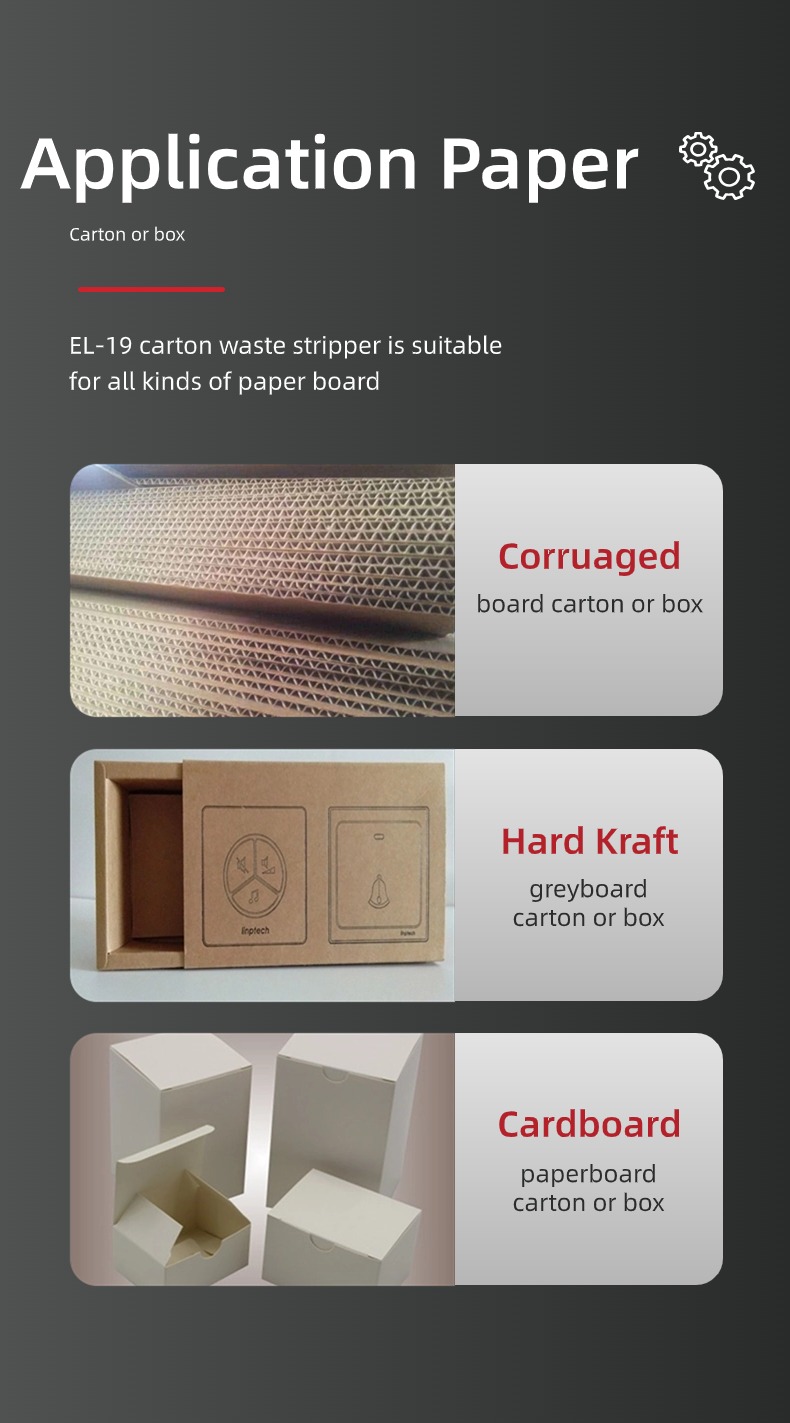

#### **Types & Applications:**

Available in various models (manual to fully automated), these strippers are widely used in industries like paper, electronics, and automotive, where precision is key.

#### **Features:**

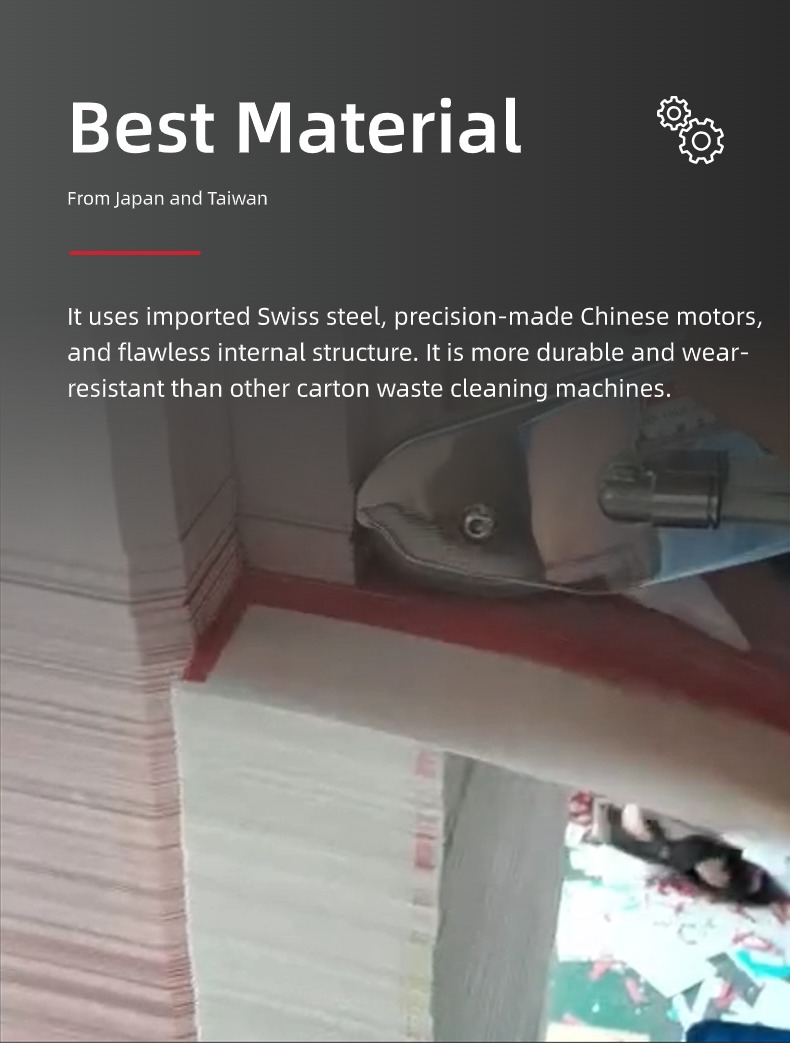

Modern die cutting waste strippers are made from durable materials and include advanced features such as photoelectric technology for monitoring and automatic lubrication systems.

#### **Advantages:**

- **Enhanced Efficiency:** Automates waste removal, reducing manual labor and human error.

- **Reliable Operation:** Gear or chain-driven systems ensure consistency.

#### **Choosing the Right Machine:**

Select a stripper based on production scale, power requirements, and capacity. Machines can process up to 80 pieces per minute, depending on the model.

#### **Operational Considerations:**

Consider power supply, machine weight, and efficiency when integrating the stripper into your production line.

### **Electric vs. Pneumatic Die Cutting Waste Strippers:**

- **Power Source:**

Electric strippers are powered by electricity, offering reliable, continuous operation without needing external equipment. Pneumatic strippers rely on compressed air and require an air compressor.

- **Control & Precision:**

Electric models provide adjustable settings for depth and speed, offering more precision. Pneumatic models offer less control due to air pressure variability.

- **Portability:**

Electric strippers are lightweight and portable, ideal for mobility. Pneumatic models are less portable due to the need for an air compressor and hoses.

In summary, electric waste strippers are ideal for precise, portable operation, while pneumatic models are better for high-power applications that can rely on compressed air. Choose based on your specific production needs.

EL-21 Strippers

SHENZHEN CHAOYI MACHINE CO.,LTD

SHENZHEN CHAOYI MACHINE CO.,LTD