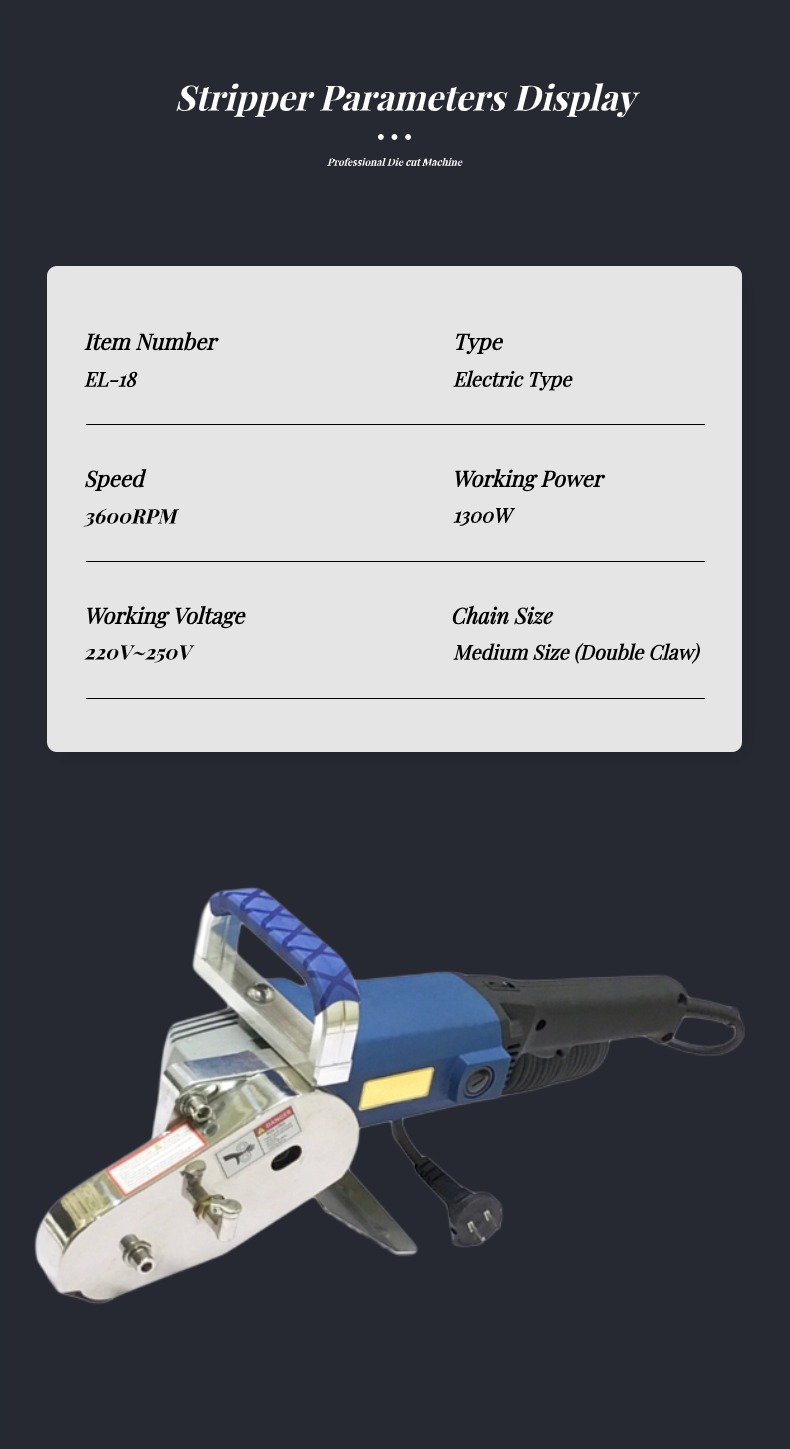

Electric Automatic blanking machine

Technical Characteristics

|

Item Number |

EL-18 |

|

Type |

Electrical stripper |

|

Color |

BLUE |

|

Revolution |

3800 turns /min |

|

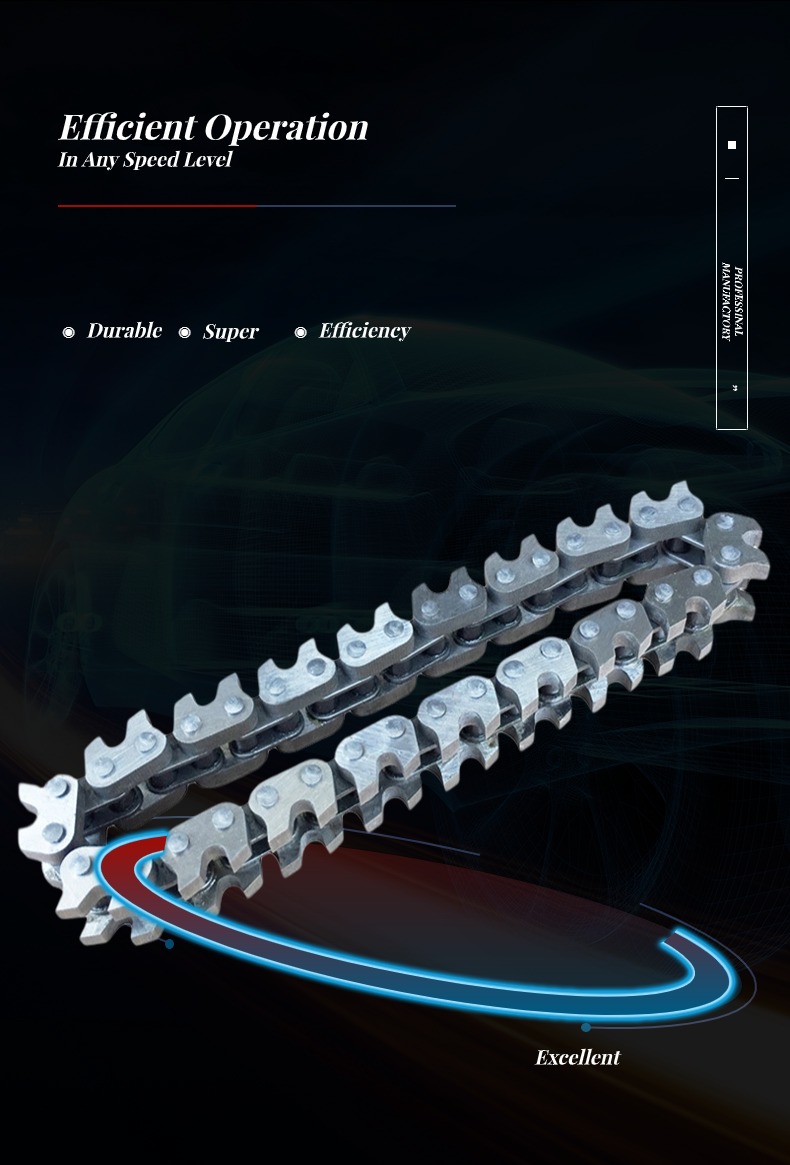

Chain |

#3 with 18 cogs (large size) |

|

Working power |

1400W |

|

Power supply |

220v~250v |

|

Net weight |

5.5 KG |

|

Minimum cutting size |

5MM |

|

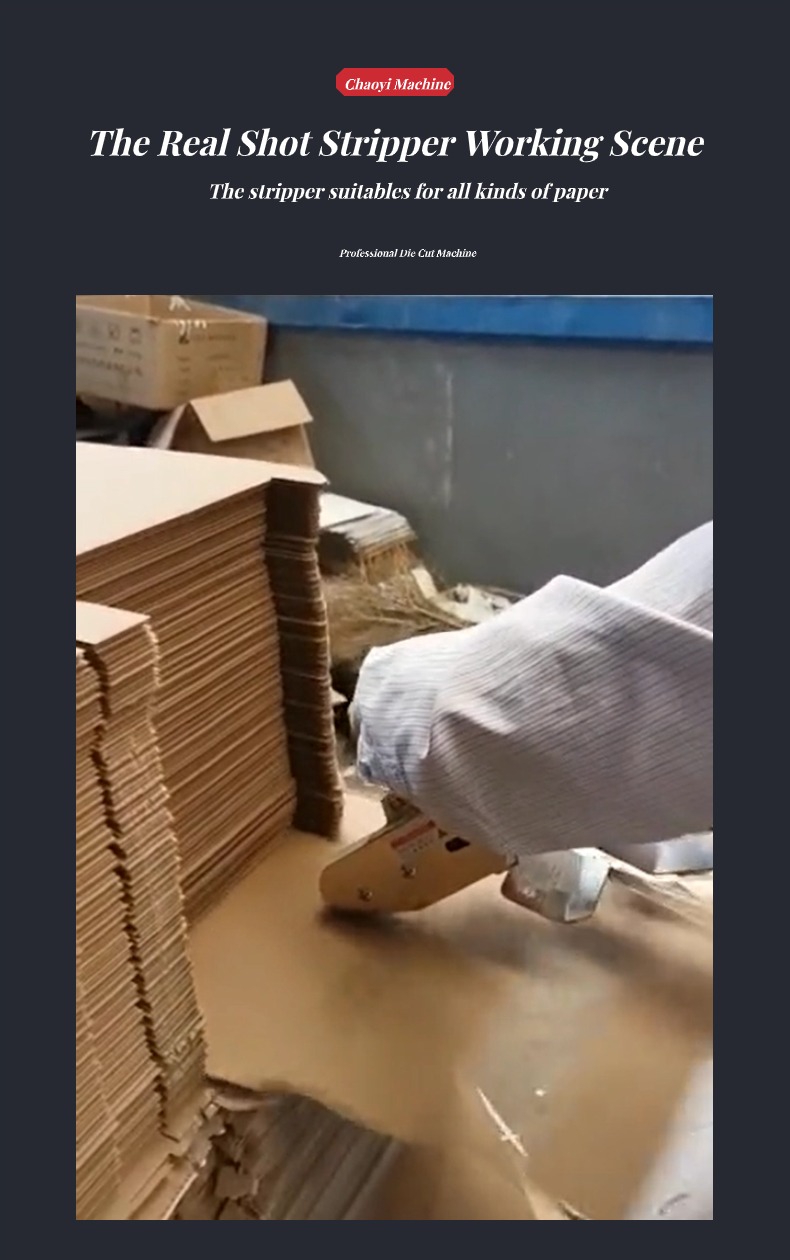

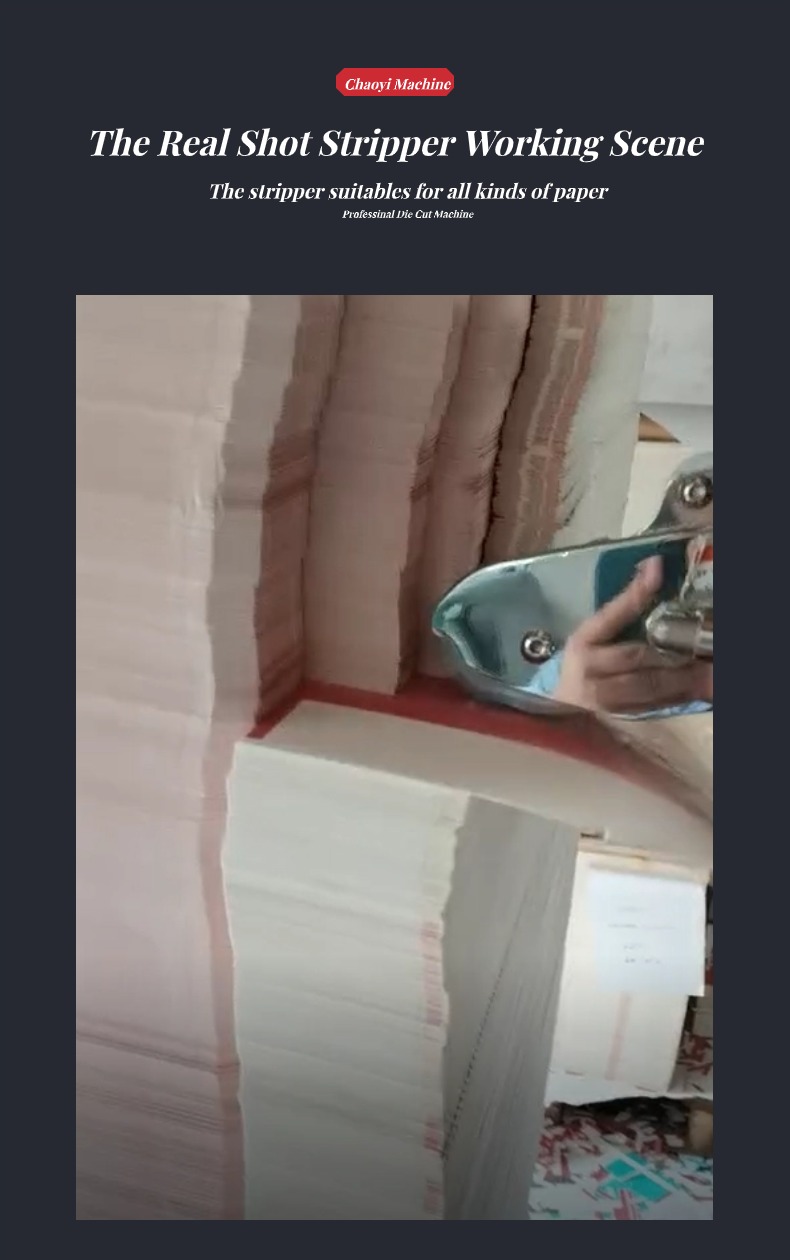

Suitable paper |

all kinds of paper. Efficiency will be higher for kraft paper / corrugating medium paper |

|

Gross Weight |

6.5KG |

|

Package Dimensions |

490*170*240mm |

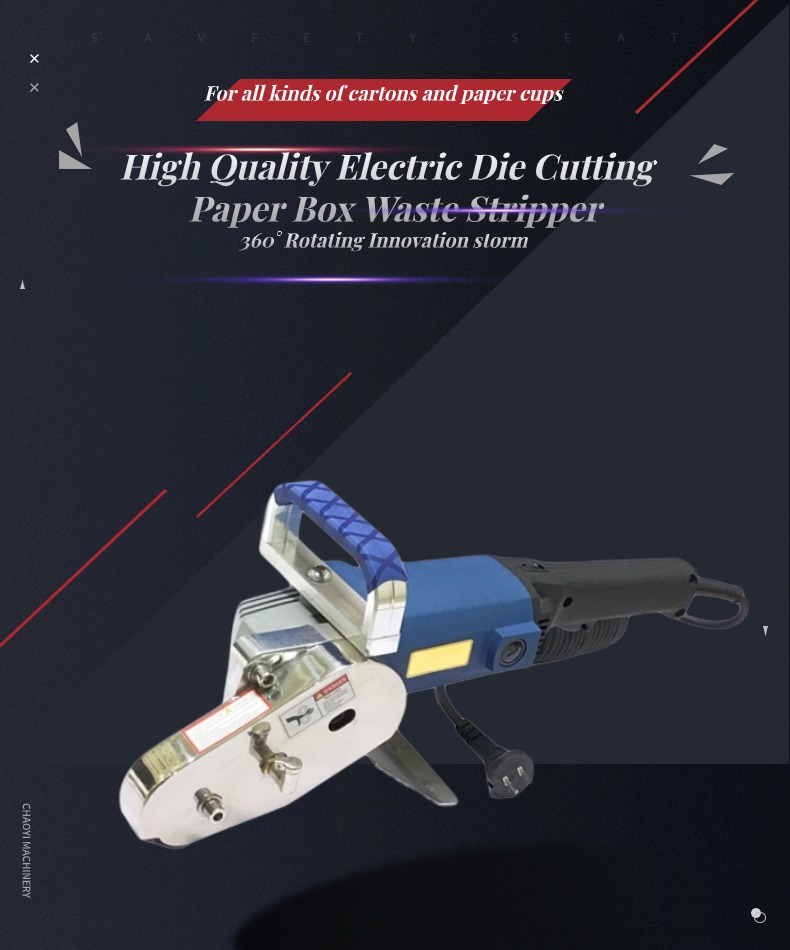

**EL-18 High-Speed Electric Waste Stripper for Paper Carton Board**

The **EL-18 High-Speed Electric Waste Stripper** is engineered to efficiently remove waste margins from various types of paperboard, including cardboard, thin corrugated paper, and standard corrugated paper. It is specifically designed for use in the printing industry where precise and quick waste removal is crucial for maintaining production flow and ensuring the quality of finished products.

**Efficiency and Time Savings:**

Manual stripping of waste edges can be a labor-intensive process, often taking several hours to complete. In contrast, the EL-18 electric waste stripper can perform the same task in just 10 to 30 minutes, dramatically improving the stripping efficiency by nearly 10 times. This time-saving capability not only increases overall productivity but also significantly shortens the delivery cycle, allowing businesses to meet tighter deadlines and improve customer satisfaction.

**Safe and Clean Operation:**

Unlike traditional methods, the EL-18 ensures that no damage is done to the bonding areas of the paperboard during the stripping process. This feature helps maintain the integrity of the material while enhancing efficiency and minimizing material waste. The precise operation prevents any unwanted tearing or damage that could compromise the quality of the final product.

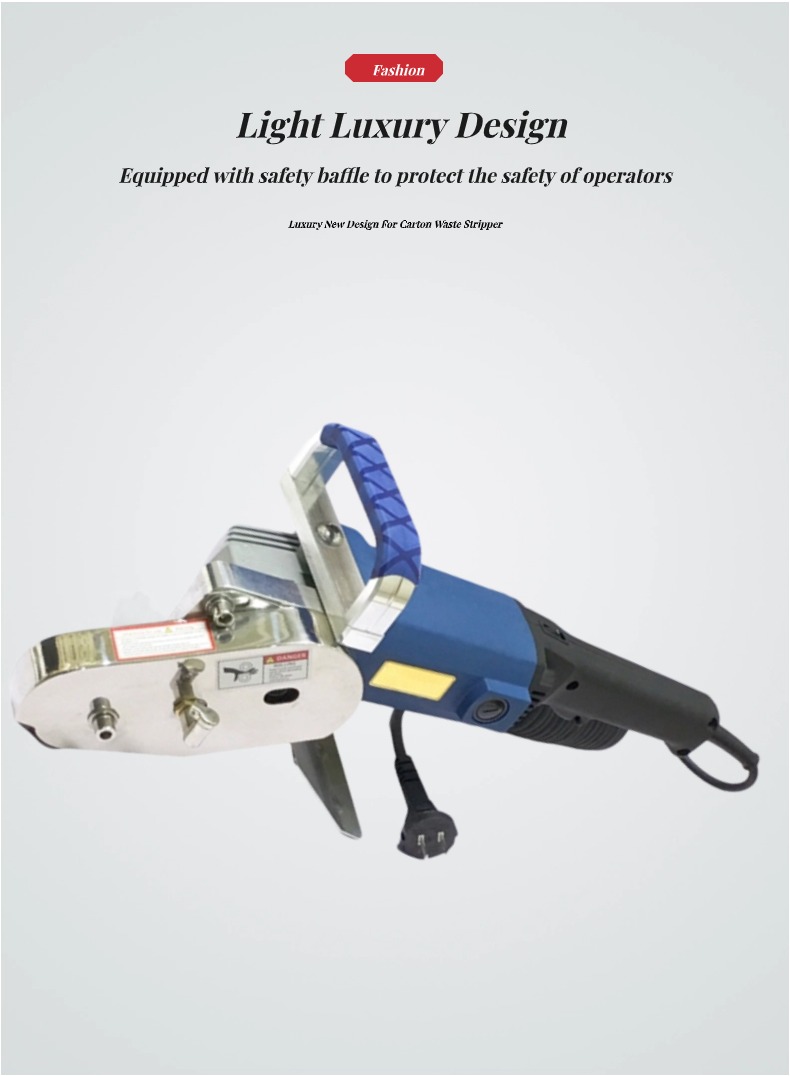

**User-Friendly and Ergonomic Design:**

The EL-18 features a compact, lightweight design similar to that of a portable polishing machine, making it easy to handle and operate. Despite its power and efficiency, the machine is designed for ease of use. After a brief training session, operators of varying skill levels—whether male or female—can quickly adapt to and operate the machine safely. This user-friendly design reduces the learning curve and increases overall workplace efficiency.

**Safety and Injury Prevention:**

The EL-18 helps reduce the occurrence of common industrial injuries associated with manual waste removal, such as wrist strain, back and shoulder pain, and repetitive motion injuries. By automating the waste removal process, the machine minimizes the physical demands on workers, contributing to a safer and more comfortable working environment.

**Durability and Low Maintenance:**

The machine’s tooth chain is made from high-strength alloy steel and undergoes a specialized heat treatment process. This treatment results in a chain that is not only highly durable but also resistant to wear and tear, ensuring a long service life. The design allows for easy replacement of the chain, reducing downtime and maintenance costs.

**Advantages of the EL-18 Electric Waste Stripper Over Pneumatic Models:**

- **Convenience:** Unlike pneumatic models, which require a fixed air compressor for operation, the EL-18 is fully electric and can be easily relocated to different workstations. It operates with a simple connection to a standard 220V~250V power supply, eliminating the need for additional equipment and making it suitable for a variety of work environments.

- **Low Maintenance:** The electric motor is less vulnerable to water vapor or moisture ingress compared to pneumatic systems, which can often require frequent maintenance due to air compressor issues. As a result, the EL-18 demands minimal maintenance, reducing operational costs and downtime.

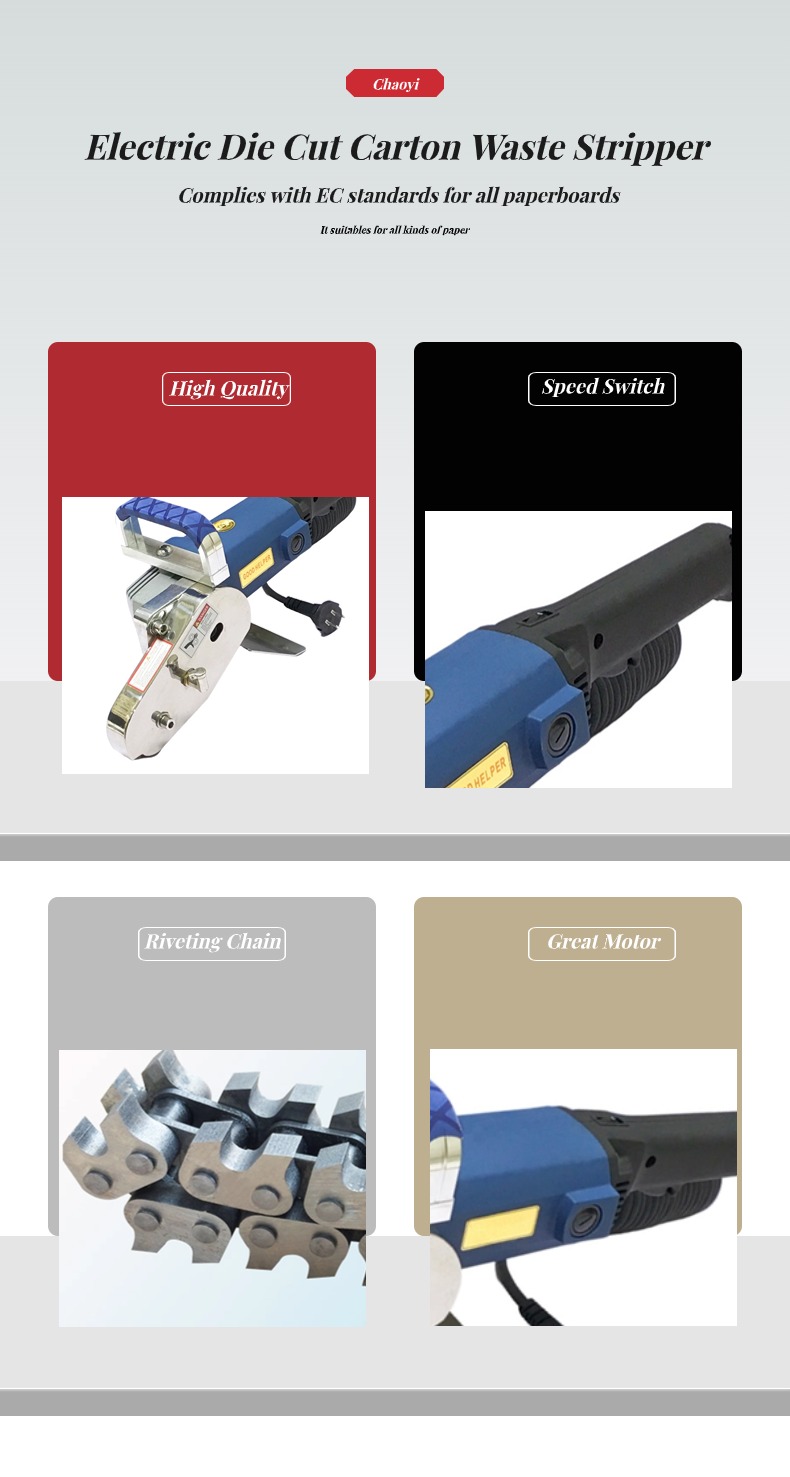

- **Adjustable Speed Settings:** The EL-18 offers six adjustable gears for speed control, providing flexibility for different types of waste removal tasks. Operators can easily adjust the speed to suit specific materials and production requirements, ensuring optimal performance and efficiency for each job.

EL-18 Display Picture

EL-18 High Power Electric Waste Remover:

Operating at 220V, this machine comes with a 2.6m extended power line and a two-pin plug for easy setup. When using the carton waste stripper, ensure that the cutter die is configured to effectively separate the waste edges, ensuring optimal waste cleaning performance.Here’s an expanded version of the **EL-18 High Power Electric Waste Remover**:

---

### **EL-18 High Power Electric Waste Remover**

The **EL-18 Electric Carton Waste Remover** is a cutting-edge, energy-efficient solution designed to significantly enhance the process of waste edge removal in carton manufacturing and printing facilities. With a powerful 1400W motor and six adjustable speed settings, this machine offers versatility and precision, ensuring optimal performance for a wide range of materials.

**Key Features & Performance:**

The **EL-18** is engineered to operate with a 220V power supply and comes equipped with a 2.6-meter power cord and a standard two-pin plug for easy setup and mobility. This ensures that the machine can be conveniently used in various locations without the need for complicated electrical installations or air compressors. It’s an ideal solution for businesses looking to streamline their waste removal process without the added complexity of pneumatic systems.

**Powerful and Efficient Motor:**

At the core of the **EL-18** is a high-performance **pure copper motor** that offers excellent stability, durability, and enhanced efficiency. The motor’s advanced design, featuring reinforced coils, ensures smooth and consistent operation, even under heavy use. This results in a significant reduction in downtime and maintenance requirements, helping you keep your production line running smoothly.

**Safety and Protection:**

The **EL-18 Electric Waste Remover** is designed with safety as a top priority. Its **main control board** is equipped with multiple protection features, including **over-current**, **over-voltage**, and **over-temperature** mechanisms. These safety features prevent the machine from operating under unsafe conditions, thereby reducing the risk of damage to both the equipment and the operator. This makes the **EL-18** a reliable and safe tool for high-volume production environments.

**Durable and Long-Lasting Construction:**

Constructed from **high-quality ABS plastic** and **stainless steel alloy**, the **EL-18** is both lightweight and durable. The combination of these materials ensures that the machine can withstand the rigors of industrial environments while meeting strict **safety production standards**. It’s built to last, providing you with years of reliable service and minimal downtime.

---

### **Operation Manual for the Electric Waste Remover:**

To ensure safe and efficient use of the **EL-18 Electric Waste Remover**, please follow the instructions below:

1. **Proper Operation:**

Always operate the machine with both hands to maintain control and ensure a safe working environment. Ensure that the power plug and connection are clean and in good condition before use.

2. **Rest Period:**

After operating the machine for 30 minutes, allow it to rest for **1 minute**. This short rest period allows the machine to cool down and promotes effective heat dissipation, extending its lifespan and enhancing operator safety.

3. **Daily Maintenance:**

Before starting each workday, make sure to lubricate the **chain** and **gears** to ensure smooth operation. Additionally, wipe down the machine’s surface to remove any dust or debris that may have accumulated overnight.

4. **Airflow and Cooling Maintenance:**

Ensure that there is no paper, debris, or other obstructions blocking the **air suction** and **exhaust** holes on the body and motor. Maintaining clear airflow channels is crucial for proper cooling and optimal performance.

5. **Cutter Die Configuration:**

Check that the **cutter die** is properly aligned and configured to effectively separate the waste edges from the material. Proper configuration is essential to ensure clean, efficient waste removal and to prevent damage to the paperboard.

By following these operational guidelines, you can maximize the performance, safety, and longevity of your **EL-18 Electric Waste Remover**, ensuring that it continues to deliver high-quality results with minimal downtime.

---

The **EL-18 High Power Electric Waste Remover** is a game-changer for businesses in the printing and carton manufacturing industries. With its energy-efficient motor, robust construction, and user-friendly design, it offers unmatched performance and safety while minimizing operational costs and downtime. Whether you're handling thin corrugated paper or standard cardboard, this versatile machine ensures that waste removal is faster, cleaner, and more cost-effective than ever before.

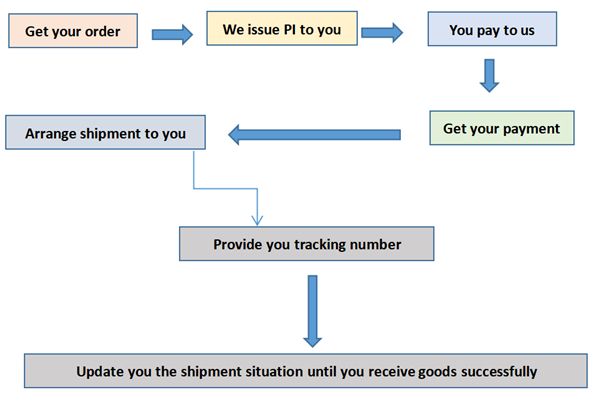

ORDER PROCESS

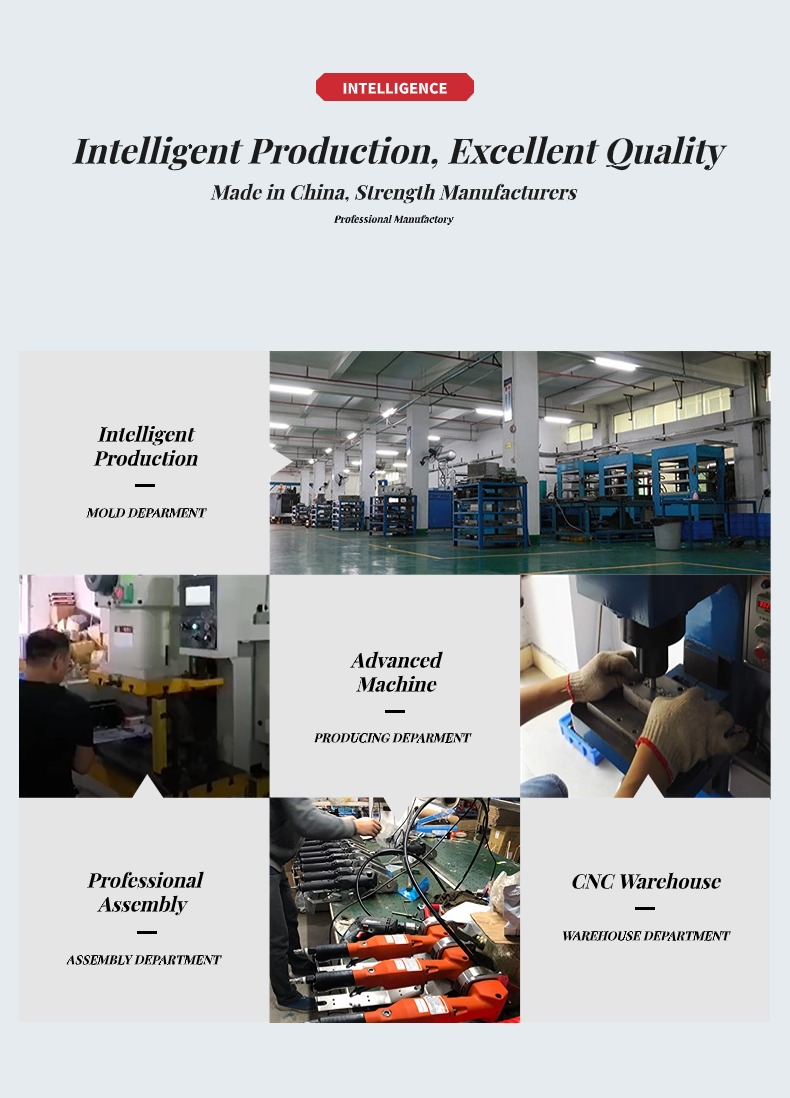

SHENZHEN CHAOYI MACHINE CO.,LTD

SHENZHEN CHAOYI MACHINE CO.,LTD