**Pneumatic Motor:** Original HEINIU from Taiwan

**Power:** 500 Watt

**Air Pressure:** 6.3 bar

**Compressed Air Consumption:** 14 l/s

**Weight:** 3.16 kg

**Chain Cover Width:** 15.5 mm

**Chain Width:** 5 mm

**Dimensions:** 38 cm x 15 cm x 20 cm

**HS Code:** 84418000

### Product Description:

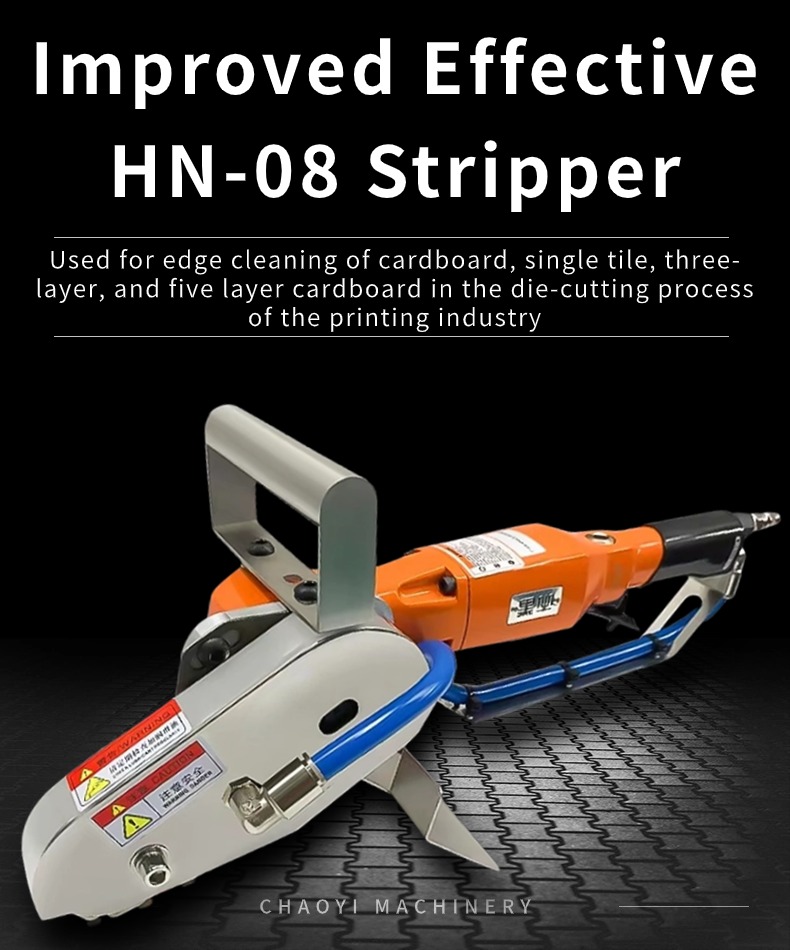

**Introducing the "New Filigree" Model**

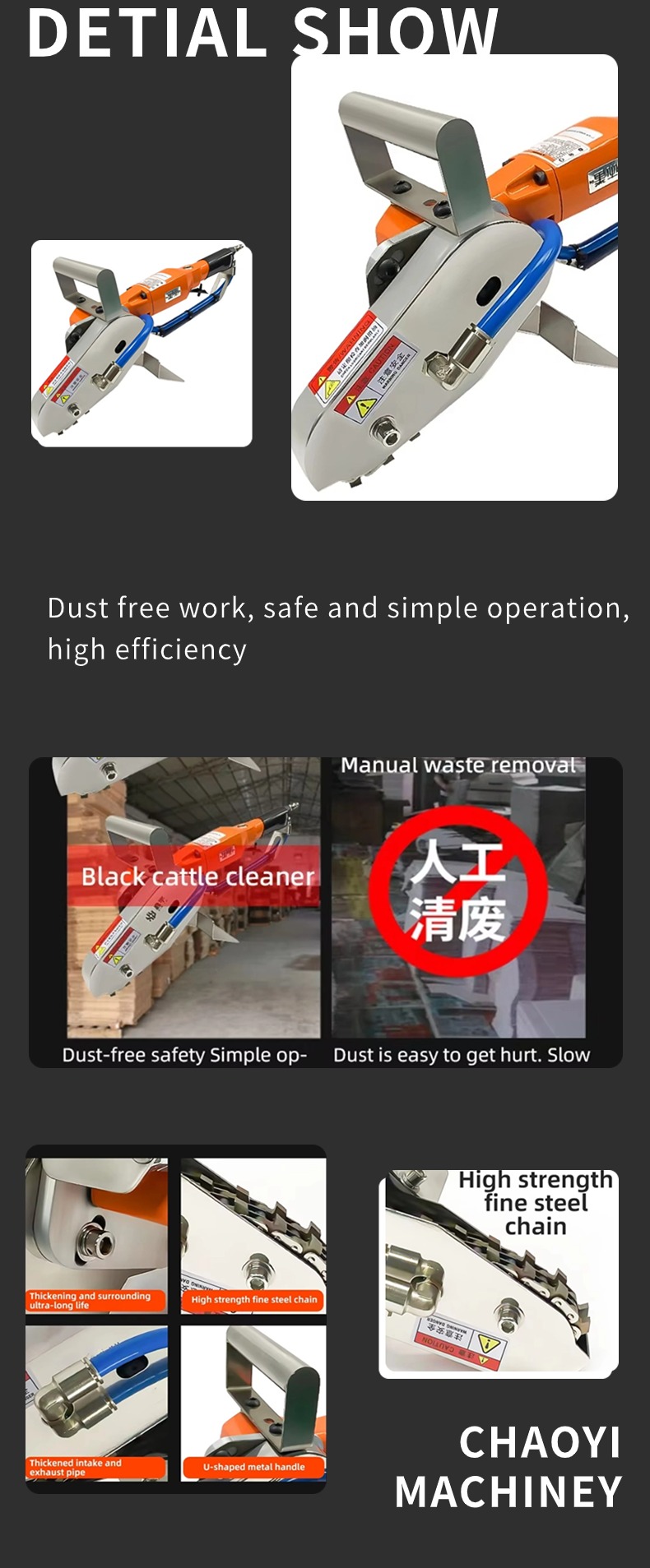

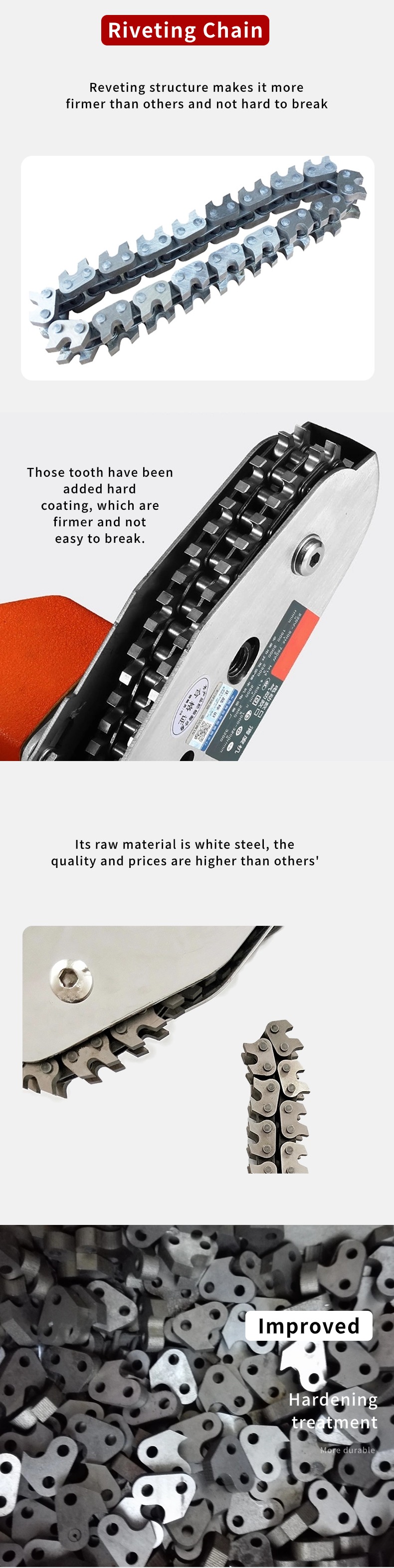

The HN-08 is a precision-designed, compressed air-powered carton waste stripper, specifically engineered to handle intricate, fine, and narrow waste removal tasks. This model is equipped with a hardened, very narrow 5mm wide chain (Chain# 3), which ensures efficient removal of even the most detailed die-cut waste. The protective cover in this version is 15.5mm wide to safely protect the chain.

Powered by the HEINIU pneumatic motor, the HN-08 offers high durability and low maintenance requirements, making it a reliable choice for demanding industrial applications. The motor's proven performance, backed by decades of expertise, guarantees high quality and exceptional reliability, which has earned the trust of numerous customers.

For optimal performance, we highly recommend pairing the HN-08 with a lubrication unit, including a filter with water separator, reduction valve, pressure gauge, air line lubricator, mounting bracket, and screws. This lubrication unit is critical to protect the air-driven motor and ensure its longevity.

---

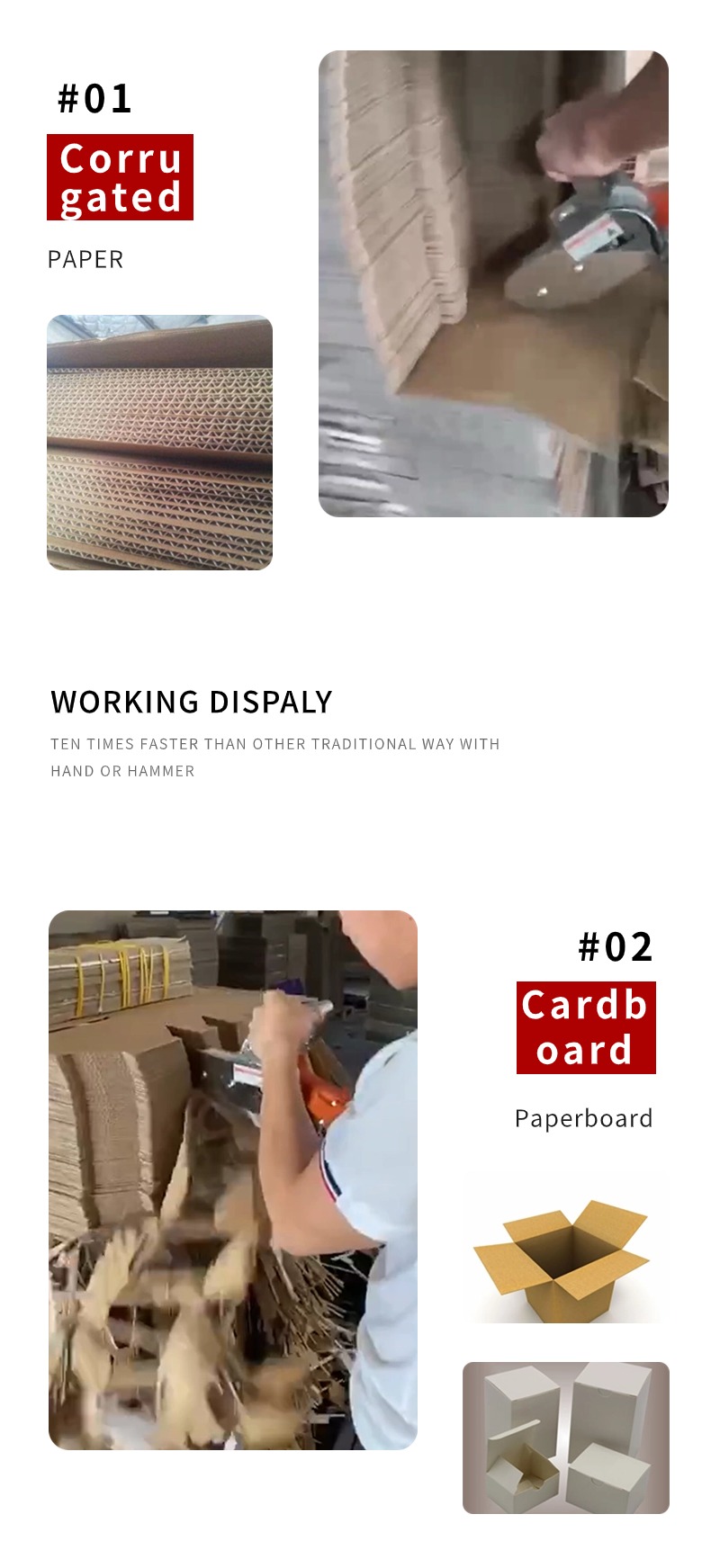

### HN-08 Applications:

The HN-08 is designed for the effective removal of external punching waste from materials such as cardboard, microwave cartons, corrugated cardboard, plastic corrugated cardboard, and similar materials with a weight of approximately 150g/m² or more. The AWEX-8AC carton stripper is the ideal solution wherever narrow and deep die-cutting waste needs to be cleared, making the HN-08 an excellent choice for these specific tasks.

Due to its fine and narrow chain design, the HN-08 is specialized for this kind of application. Converting the narrow chain to a wider version (Chain# 3) on-site is not possible for technical reasons.

For optimal performance, the width of the waste edge should be at least 5mm for cardboard and microwave cartons and at least 20mm for corrugated cardboard.

The device is supplied ready for use, with a quick-connect coupling for hoses with an inner diameter of 9mm. The package includes tools for chain replacement, as well as an operating manual (available in both German and English) and a spare parts list. Please note that, depending on availability, the device may be delivered in yellow, gray, or red paint.

---

### 01 Requirements for Use:

1. **Air Pressure:** 0.6–0.8 MPa

2. **Air Compressor Power:** 4 kW or 5.5 HP or higher

3. **Production Requirements for Supporting Die-Cutting Boards:**

To ensure optimal waste removal, it is essential that the die-cutting board is broken into smaller sections to allow the stripper to work efficiently. For best results, die-cut the external waste edges into small strips of approximately 250mm–450mm in length. The exact length of these pieces depends on the shape of the paper product, the width of the waste edges, and the number of sections required. The fewer sections and the wider the waste strips, the faster the waste can be removed.

---

### 02 Maintenance Guidelines:

1. **Routine Inspection and Lubrication:**

It is recommended to inspect and maintain the tool every two months. Check the bearings, gears, chains, and other transmission parts to ensure they are clean and well-lubricated. Apply bone grease to the motor head’s oil injection hole to ensure the internal gears are fully lubricated. For high-frequency use, we suggest checking and lubricating the tool every two weeks.

2. **Air Motor Blade Cleaning:**

Regularly clean the air motor blades based on usage conditions. The cleaning process involves loosening the air inlet pipe, injecting a small amount of low-viscosity lubricant, reconnecting the air pipe, and running the motor for about 30 seconds. Then, loosen the air pipe to drain out the dirty oil. Afterward, drip fresh lubricating oil into the motor or inject a bone moisture agent through the exhaust port.

3. **Long-Term Storage:**

If the tool is not used for a long period, it is advisable to inject a small amount of lubricating oil into the air inlet and let the tool run briefly before storing it. This ensures that the internal components stay lubricated and free from rust.

---

### Precautions:

1. **Chain Maintenance:**

After daily use, spray WD-40 anti-rust oil on the chain to clean it. Use a dust blow gun to remove paper dust, and then add a small amount of lubricating oil. Proper care and maintenance of the chain are crucial for extending its lifespan.

2. **Handling Jammed Paper:**

In the event of paper jamming, always disconnect the air circuit first (this is very important). If the chain cannot move, loosen the protective shell screws, remove each screw, and turn the rail to clear the jammed paper. Reassemble the parts and continue operation.

3. **Chain Tension:**

Regularly check the tension of the chain and adjust it as needed. After adjustment, the longest section of the chain should have a sag of about 1mm when placed in a horizontal position. If the chain is too loose, it may cause damage due to contact with the safety shield during operation.

---

By above guidelines, you can ensure that the HN-08 operates efficiently and lasts for a long time, providing consistent and reliable performance for your waste removal needs.

HN-08 Pictures Show

**Frequently Asked Questions (FAQ):**

**Q1: Are you a trader or a manufacturer?**

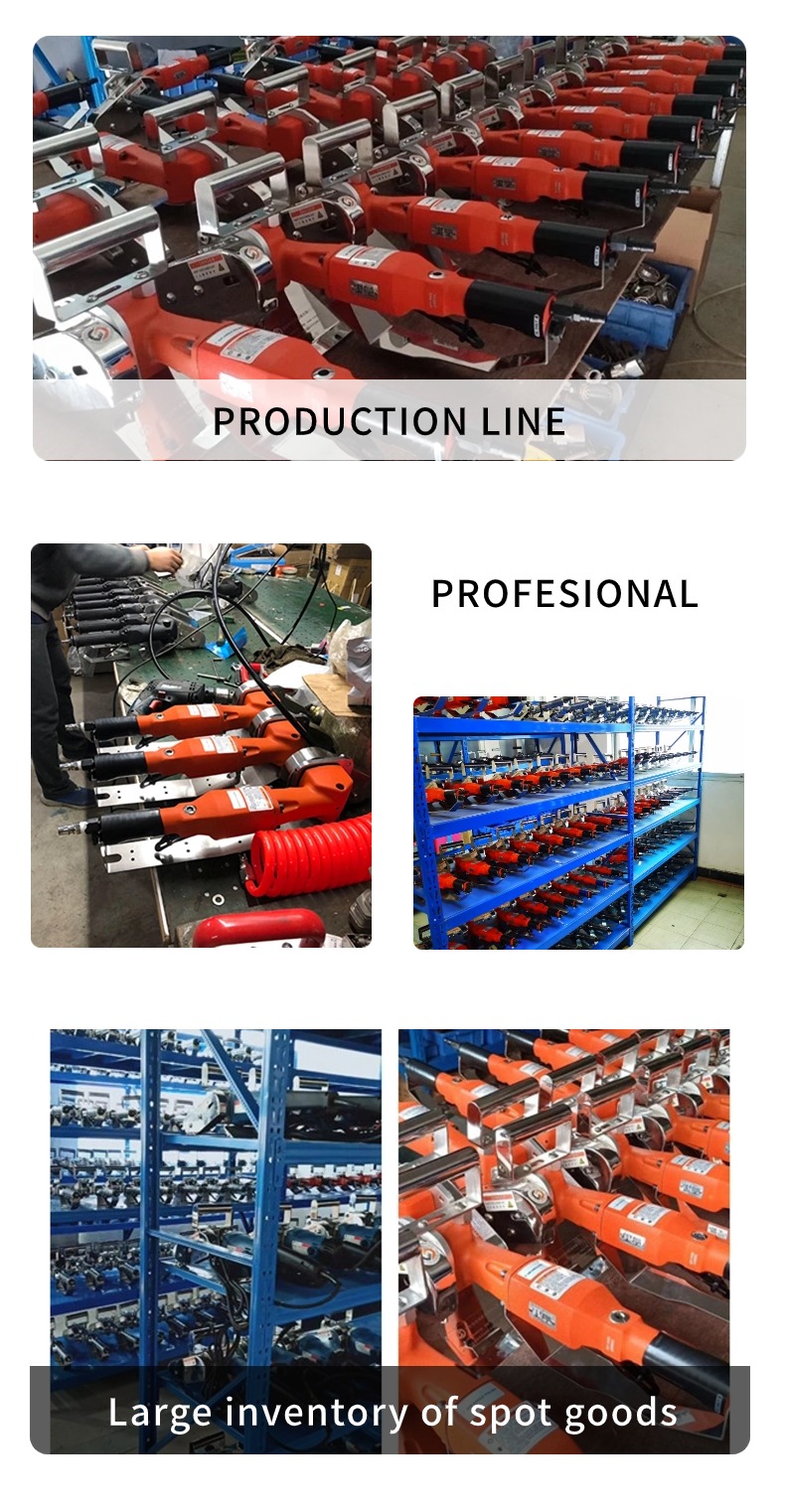

**A:** We are a direct manufacturer with official export qualifications. This means we control the entire production process from start to finish, ensuring high-quality products at competitive prices. We also offer direct customer service, which allows us to tailor solutions to your specific needs.

**Q2: Do you provide OEM services?**

**A:** Yes, we offer OEM (Original Equipment Manufacturer) services. We can customize our machines based on your requirements, including branding, packaging, and technical specifications. Whether you need specific modifications or have a unique product design in mind, we are capable of fulfilling your OEM needs.

**Q3: Where is your factory located?**

**A:** Our factory is located in Shenzhen, China. Shenzhen is one of the major manufacturing hubs in China, known for its advanced industrial infrastructure and strategic location, which makes it an ideal place for international trade.

**Q4: What is the nearest airport to your factory?**

**A:** The nearest airports to our factory are Yantian and Shekou in Shenzhen. Both airports are conveniently located, with easy access to the city center and other key areas in the region. Depending on your travel needs, these airports provide great connectivity for international and domestic flights.

**Q5: What is the nearest high-speed train station, and how long does it take to get to your factory from there?**

**A:** The nearest high-speed rail station is **Shenzhen North Station**, which is approximately 1 hour away from our factory by car or public transportation. Shenzhen North is a key hub for high-speed rail travel, with fast connections to major cities across China.

**Q6: What is your business process?**

**A:** Our business process is straightforward and customer-focused:

1. **Discuss Client Requirements:** We start by understanding your specific needs and discussing the product features that would best suit your application.

2. **Confirm Machine Specifications:** We then confirm the machine specifications, ensuring they align with your operational requirements.

3. **Make Sales Contract:** Once the specifications are confirmed, we draft a sales contract outlining the terms and conditions.

4. **Deposit Payment:** The client makes a deposit to begin the manufacturing process.

5. **Production:** After receiving the deposit, we schedule and begin production.

6. **Quality Check & Testing:** Once the machines are finished, we conduct a thorough testing phase to ensure they meet quality standards.

7. **Balance Payment:** Upon successful machine testing, the client pays the remaining balance.

8. **Delivery:** Finally, we arrange for shipping and delivery to the client’s destination.

**Q7: How do you control the quality of your machines?**

**A:** At CHAOYI, machine quality is the cornerstone of our business. We have implemented a rigorous quality control system that spans the entire production process, from raw material sourcing to final delivery:

1. **Strict Quality Control System:** Our quality control system is implemented at every stage of production to ensure that each machine meets our high standards.

2. **Environmental Protection:** All materials used in the production of our machines are environmentally friendly and non-polluting, ensuring that our machines are not only high-quality but also safe for the environment.

3. **Experienced Technicians:** We have a team of highly skilled technicians who supervise production and ensure that each machine is built according to specifications.

4. **Professional Inspection Team:** A dedicated quality control team thoroughly inspects every step of the production process, from component assembly to final testing, to ensure that the final product meets the highest standards of quality.

**Q8: Can your engineers travel abroad to debug machines?**

**A:** Yes, our engineers are available to travel abroad to assist with machine installation, debugging, and training. However, the client will need to cover the following costs:

- **Round-Trip Airfare:** The cost of the engineer's round-trip flight.

- **Accommodation & Meals:** The cost of lodging and meals for the engineer during the stay.

- **Daily Salary:** A daily salary of $80 USD per day for the engineer's services.

Our engineers are highly trained and experienced, and they can provide on-site support to ensure the machine is set up and operating as expected.

SHENZHEN CHAOYI MACHINE CO.,LTD

SHENZHEN CHAOYI MACHINE CO.,LTD