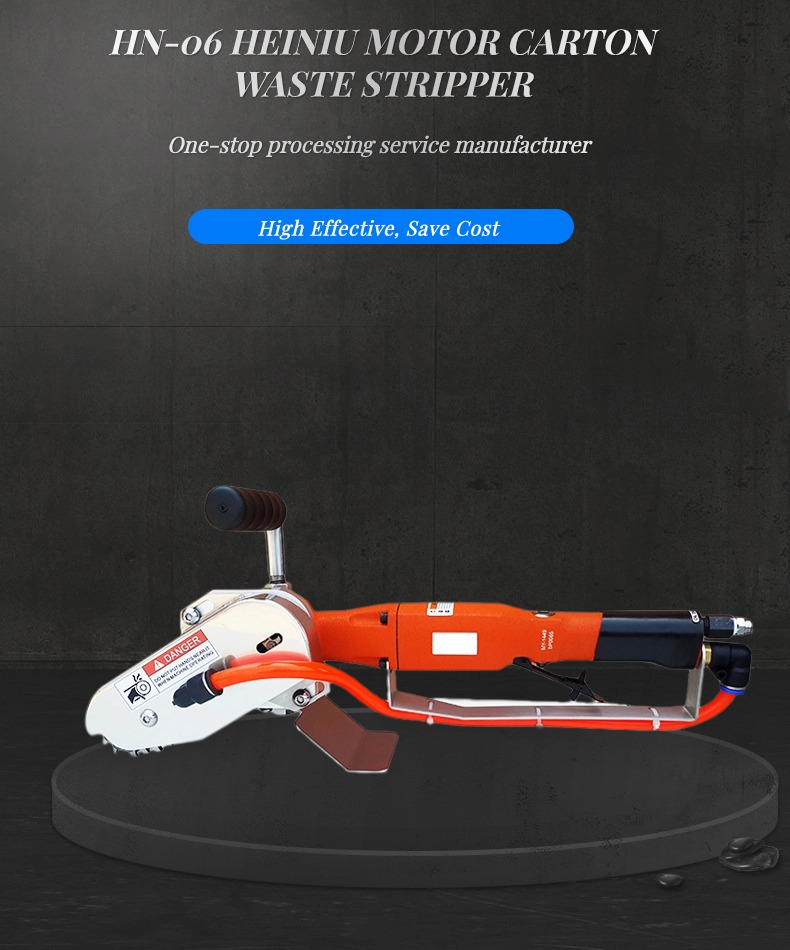

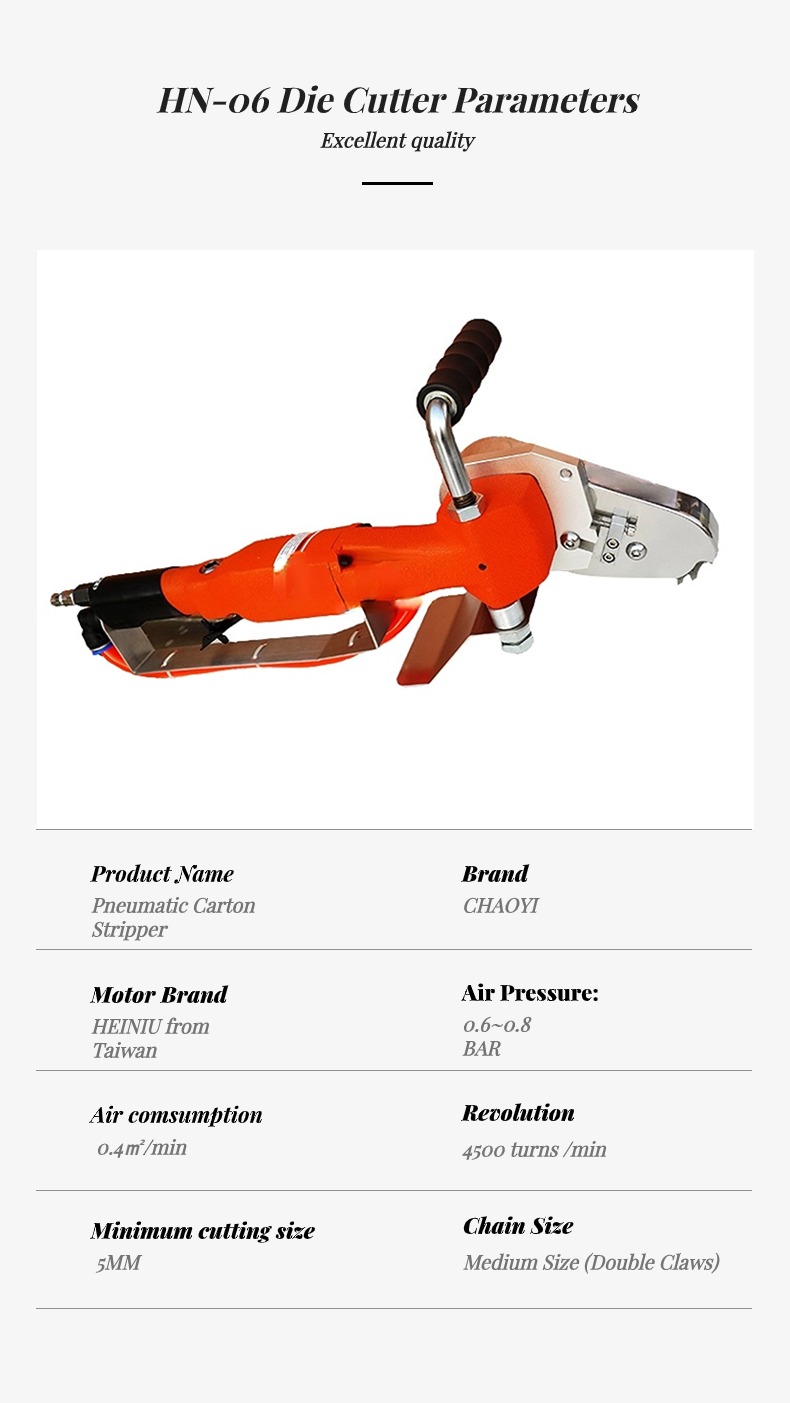

Manufacturer: CHAYI

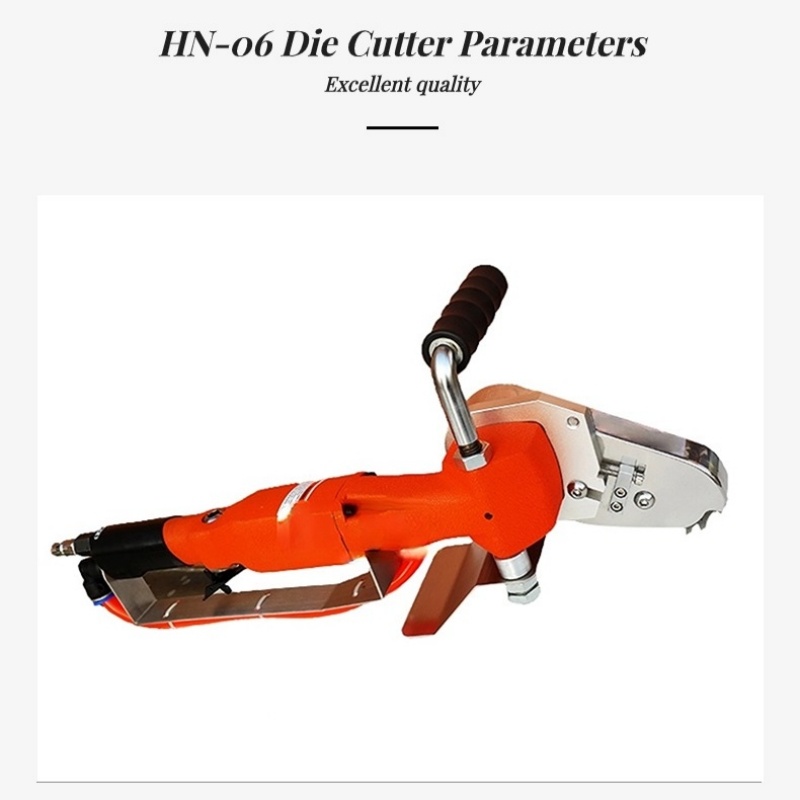

Part Number: HN-06

Weight: 11.62 lbs

Dimensions: 23.25 x 9.25 x 7 inches

Model Number: HN-06

Discontinued: No

Color: Double Claw Chain

Material: Metal

Batteries Included: No

Batteries Required: No

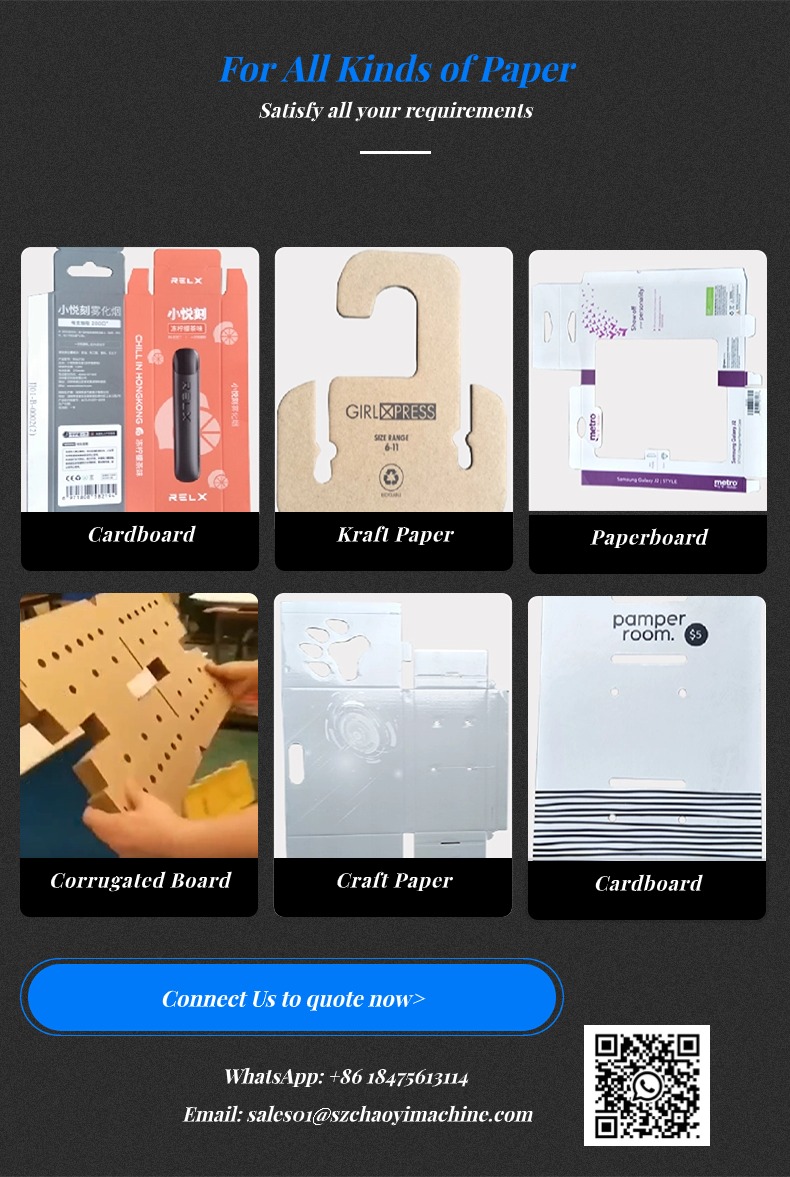

PRIMARY APPLICATION - Designed for use in the printing industry to clear or crush waste edges from cardboard, corrugated board, and standard corrugated paper.

SPECIFICATIONS FOR REFERENCE - Picking Frequency: 4500 RPM, Air Consumption: 0.4 m³/min, Air Pressure: 6-8 kg, Air Tube Size: 8*12 mm, Weight: 3.6 kg.

HIGH PERFORMANCE TOOL - Equipped with a pneumatic motor that offers excellent performance and safety, enhancing efficiency while ensuring user safety!

HIGH QUALITY TOOL - The hard alloy chain hook, treated with nanotechnology, guarantees a long service life and effective operation at high speeds.

THOUGHTFUL STRUCTURAL DESIGN - The tail features an exhaust system to prevent air pollution; the ergonomically designed structure ensures high adaptability for various applications.

The carton stripper offers a safe and cost-effective solution for removing waste paper from die-cut sheets, cardboard, and corrugated board.

This waste stripper features a multi-tooth chain drive powered by a compressor air motor with a speed of 4500 RPM. Instead of cutting the paper, the teeth grip it, allowing the operator to simply hold the device. The waste stripper completes this task up to 10 times faster than manual methods.

Designed for stripping waste margins from cardboard, thin corrugated paper, and standard corrugated paper in the printing industry, the high-speed gear is driven in cycles by the air motor, utilizing sharp-toothed gears to strip waste margins. The gears are made from high-strength diamond compound and undergo heat treatment, ensuring high hardness, wear resistance, long lifespan, and easy replacement.

This product is a highly efficient manual stripping tool, increasing stripping efficiency by 10 times. While manual stripping can take hours, the machine can complete the task in just 10 to 30 minutes, significantly reducing delivery times.

With a compact design and a weight comparable to a standard grinder, it is user-friendly. Workers can operate the machine after minimal training. The stripping process does not damage the bonding area, enhancing the efficiency of subsequent processes such as gluing and automatic packing.

01 Usage Requirements

Air Pressure: 0.6 to 0.8 MPa

The air compressor should have a capacity of 4 kW, 5.5 HP, or higher.

Production Requirements for Die-Cutting Boards (Very Important!)

To optimize performance with the waste stripper, the die-cutting boards should be divided into several sections as per the specifications. This allows the stripper to efficiently remove smaller pieces of waste. Ideally, the external waste edges should be die-cut into strips measuring between 250 mm and 450 mm in length. The exact length of these strips will depend on the shape of the paper product, the width of the waste edges, and the number of sections. Fewer, wider strips will facilitate faster waste removal.

02 Maintenance Guidelines

It is advisable to inspect and maintain the cleaning tools approximately every two months. Check that bearings, gears, chains, and other moving parts are well-lubricated and clean. Inject bone grease into the oil hole of the motor head to ensure the internal gears are fully lubricated. For tools used frequently, routine checks and lubrication every two weeks are recommended.

Regularly clean the air motor blades based on usage conditions. To clean, loosen the air inlet pipe, inject a small amount of low-viscosity lubricant, reconnect the air pipe, and run the motor for 30 seconds. Then, loosen the air pipe to drain the dirty oil, followed by adding a small amount of lubricating oil. You can also inject other moisturizing agents through the exhaust port.

If the tool is not used for an extended period, it is advisable to add a small amount of lubricating oil through the air inlet and run the tool for a few seconds before storage to keep the internal components lubricated and prevent rust.

Precautions

After daily use, spray WD-40 anti-rust oil on the chain to clean it, use a dust blower to remove paper dust, and then apply a small amount of lubricating oil. Proper maintenance is crucial for extending the chain’s lifespan (very important).

Dealing with Jammed Paper: Disconnect the air supply (very important). If the chain is stuck, loosen the screws on the protective cover, remove each screw, and turn the rail to clear the jammed paper before reassembling the screws to continue operation.

Regularly check the chain tension and adjust as necessary. After adjustment, if the longest section of the chain sags about 1 mm when horizontal, the tension is likely correct. A chain that is too loose may collide with the safety shield during operation, causing damage.

FAQ:

Q1: Are you a trader or a manufacturer?

A: We are a manufacturer with export qualifications.

Q2: Do you offer OEM services?

A: Yes, we can provide OEM services.

Q3: Where is your factory located?

A: Our factory is located in Shenzhen, China.

Q4: What is the nearest airport to your factory?

A: The nearest airports are Yantian and Shekou, both in Shenzhen.

Q5: Where is the closest high-speed train station, and how long does it take to get to the factory?

A: The nearest high-speed train station is Shenzhen North, and it takes about 1 hour to reach the factory.

Q6: What is your business process?

A: Our process involves discussing client requirements, confirming the machines, drafting a sales contract, paying a deposit, arranging production, completing the machines, allowing the buyer to test them, receiving the balance payment, and finally delivering the machines.

Q7: How do you ensure machine quality?

A:

At CHAOYI, machine quality is our priority, and we have a strict quality control system from production to delivery.

All materials used are environmentally friendly and non-polluting.

We employ professional technicians to supervise production.

A dedicated department examines every stage of the production process.

Q8: Can your engineers travel abroad for machine debugging?

A: Yes, our engineers can travel abroad for machine debugging, but the buyer is responsible for the engineers’ round-trip airfare, accommodation, meals, and a salary of $80 per day.

SHENZHEN CHAOYI MACHINE CO.,LTD

SHENZHEN CHAOYI MACHINE CO.,LTD