Semi-automatic Paper Box Inner Hole Waste Cleaner

Technical Information

|

Name |

Split-hole Waste Carton Stripper |

|

Item No. |

CY-50001 |

|

Voltage |

220V |

|

Atmospheric |

0.8BAR |

|

Pressure |

1.5T |

|

Course |

150MM |

|

Working Size |

500*480mm |

|

Application |

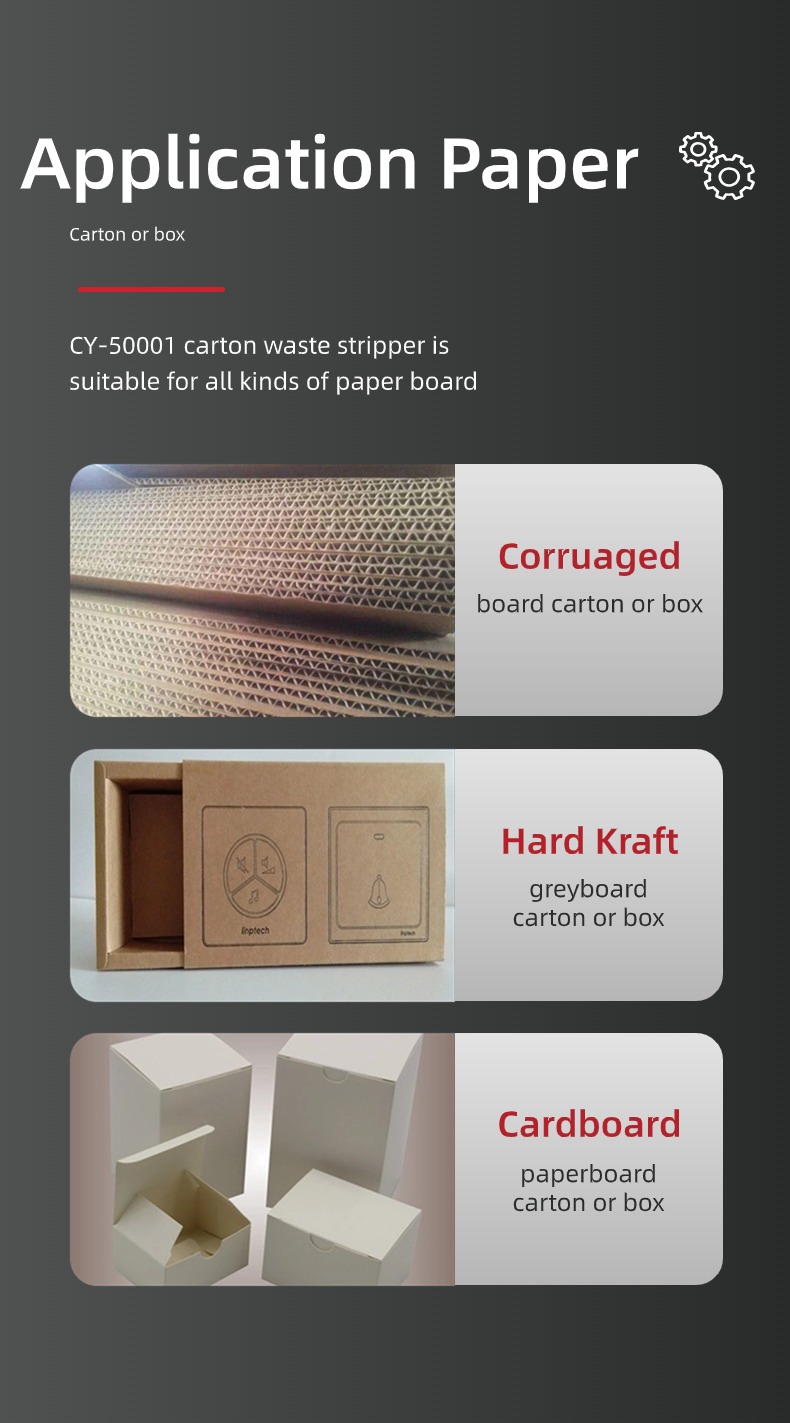

suitable for all kinds of paper |

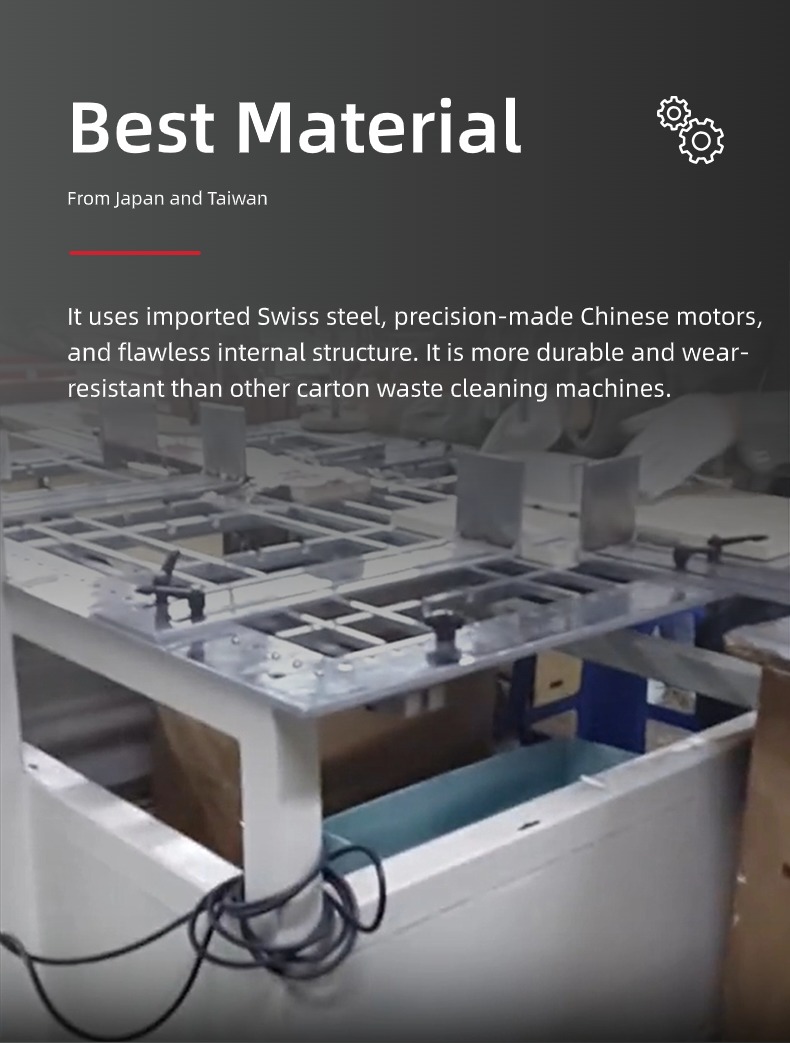

**Pneumatic Inner Hole Waste Stripping Machine**

This machine is designed for the removal of inner hole waste (round holes, square holes, long holes, airplane holes, etc.) from color boxes and cartons after die-cutting. It is widely used in color printing and packaging industries for cleaning waste from tags, cartons, and color boxes. Multiple holes can be cleared simultaneously for higher efficiency.

**Key Features:**

1. **High Accuracy & Easy Operation:** Precise performance with user-friendly controls.

2. **Customizable Molds:** Molds can be added or reduced, allowing simultaneous cleaning of multiple waste holes.

3. **Non-destructive Punching:** The machine applies pressure without damaging the product integrity.

4. **Built-in Cleaning Box:** Convenient waste collection and disposal.

**Product Description:**

The **CY-50001 Pneumatic Stripping Machine** is designed to remove excess material from paper, corrugated cardboard, plastic, foam, and rubber. It accommodates a variety of stripping tools and separation plates, with precise vertical guidance for the stripping plate. The machine’s adjustable locking plate can hold multiple molds, clearing numerous waste holes in a single cycle, reducing labor and improving efficiency.

This semi-automatic waste removal machine is ideal for removing waste from color box inner holes (aircraft holes, round holes, square holes, etc.) after die-cutting. It significantly reduces manual labor, lowers production costs, and increases efficiency by 30%-50%.

**Benefits:**

- Saves labor costs by automating waste removal.

- Reduces product damage and improves quality.

- Enhances production efficiency, especially for products with multiple holes.

- Simple, safe, and easy to operate with minimal training required.

**Additional Features:**

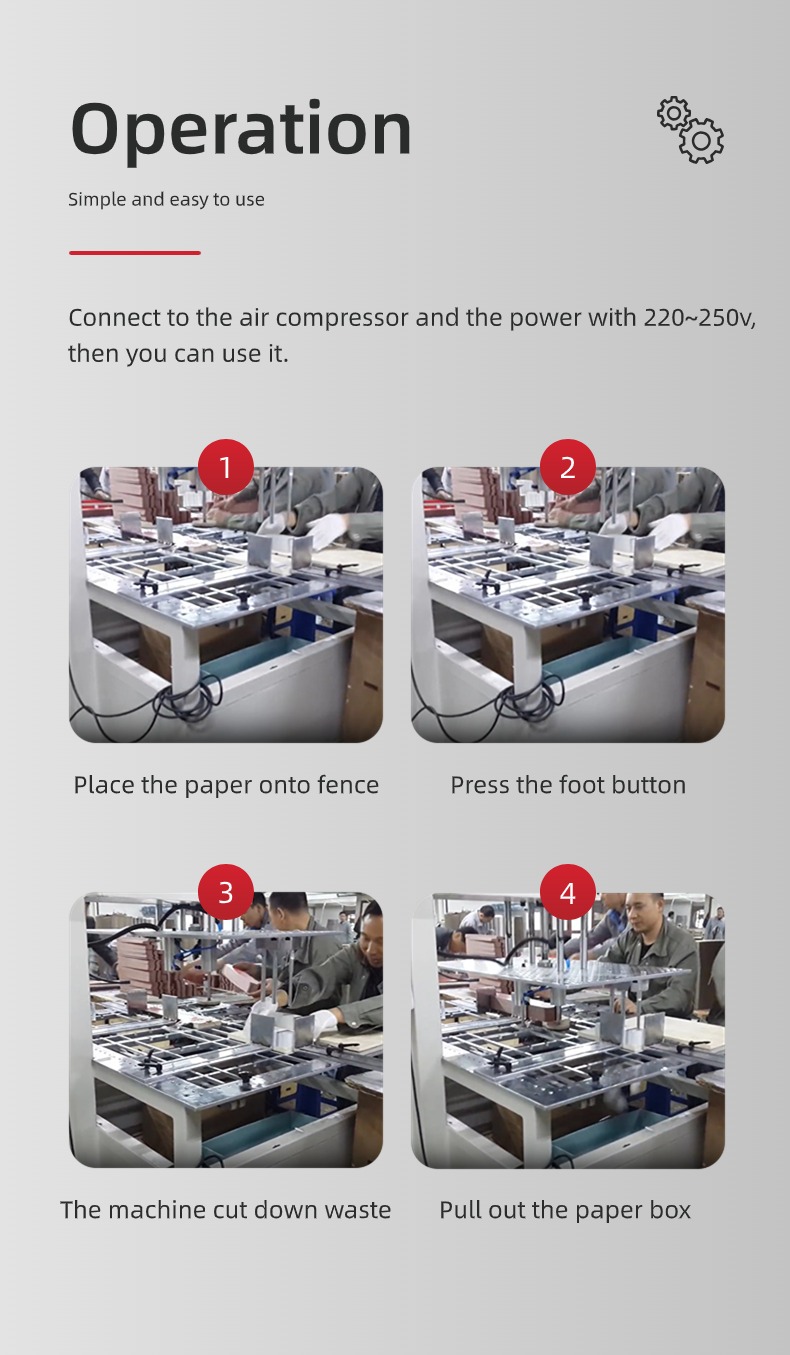

- Foot pedal activation with safety light barriers.

- Clear visual indicators for operational status.

- Quick setup and changeover for new tasks.

- Convenient waste disposal and universal tool compatibility.

- Safety optical barrier to prevent unauthorized use.

This machine is a cost-effective and efficient solution for packaging and printing industries, offering significant labor savings and improved production quality.

CY-50001 Photos Show

**Why Choose Us?**

At **CY-50001**, we focus on providing advanced solutions that ensure safety, efficiency, and ease of use in the waste removal process. Our machine is built with cutting-edge features designed to optimize your production line, save costs, and improve overall operational safety and productivity. Here’s why you should choose our machine:

1. **Infrared Safety Detection Sensor**

Safety is our priority. The **infrared safety detection sensor** ensures that the machine will not press down if there is any obstruction, such as a hand, left on the working desk. This feature prevents accidents and ensures that your operators are always protected during the waste removal process. With this sensor, the machine automatically detects when it’s safe to operate, providing a secure working environment.

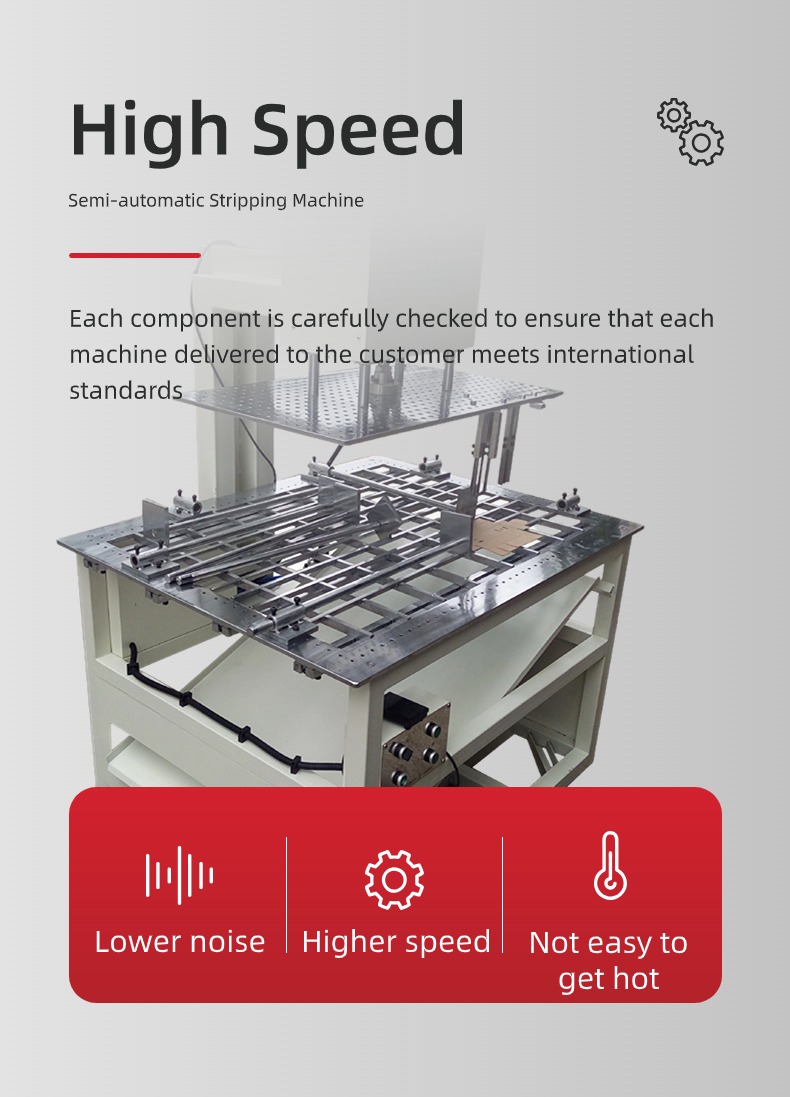

2. **Large Size Double Magnetic Ring Cylinder**

The **125-type large size double magnetic ring cylinder** is a core component that guarantees stable machine operation. This advanced cylinder ensures smoother and more reliable waste paper removal. It also contributes to the overall durability of the machine, enhancing its longevity and minimizing maintenance needs, which translates into better long-term value for your business.

3. **Foot Switch**

The **high-grade foot switch** is designed for automatic waste cleaning. It is housed in a metal, anti-misstep casing, which ensures that the operator can safely and easily activate the waste removal process without having to manually press buttons. The foot switch is ergonomic, improving ease of use and minimizing operator fatigue, allowing for hands-free operation while focusing on other tasks.

4. **Additional Working Desk**

The **additional working desk** expands the material preparation area, providing ample space to set aside the products. This added desk increases the product drag-and-drop length, making it more convenient for the operator to position the material for efficient waste clearance. With more space, operators can work faster and more comfortably, reducing handling time and improving overall workflow.

**CY-50001 Advantages**

The **CY-50001 Pneumatic Inner Hole Waste Stripping Machine** is not just a piece of equipment—it’s a productivity-enhancing solution. Here are some of the key advantages that set our machine apart:

1. **Minimize Manual Waste Removal**

By automating the waste removal process, the **CY-50001** eliminates the need for manual labor, which is both time-consuming and prone to error. This automated system allows operators to focus on more complex tasks, while the machine takes care of the repetitive waste clearing, improving overall productivity.

2. **Reduce Labor Costs and Product Damage**

With the reduction of manual intervention, our machine helps lower labor costs significantly. By automating waste removal, the risk of product damage due to human error is minimized, enhancing the overall quality of your products. Less damage means fewer returns and higher customer satisfaction.

3. **Achieve 40%-60% Higher Production Efficiency**

The CY-50001 increases production efficiency by up to **60%**. With the ability to handle large volumes of products and multiple waste holes simultaneously, the machine processes more materials in less time. Unlike traditional manual methods, the **CY-50001** speeds up production, resulting in a significant increase in output and a more efficient use of resources.

4. **Higher Efficiency for Products with Multiple Holes**

The CY-50001 is especially effective for products with multiple holes, as it can clean waste from several holes in one go. This eliminates the need for multiple operations, saving time and improving workflow. Whether you’re working with round holes, square holes, or custom shapes, the machine offers specialized molds and needles to meet specific production needs.

5. **Compact Design & User-Friendly Operation**

The machine features a **compact design** that fits easily into your production line without taking up excessive space. Despite its powerful functionality, it’s incredibly **user-friendly**. Both male and female operators can handle the machine with basic training. Its intuitive interface ensures that even operators with minimal technical experience can quickly learn to operate it effectively.

Choosing **CY-50001** means opting for a reliable, efficient, and safe solution that boosts productivity, reduces labor costs, and ensures higher quality products. With advanced features such as the infrared safety sensor, large double magnetic ring cylinder, foot switch, and additional working desk, our machine provides everything you need for a streamlined, high-performance waste removal process. Save time, reduce costs, and improve your production capabilities with **CY-50001**.

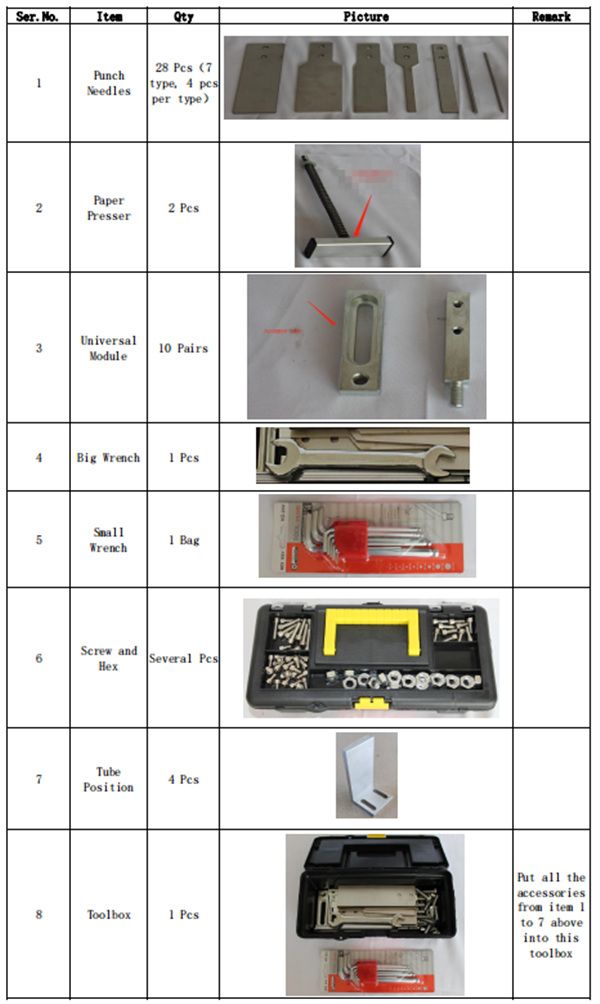

Accessory List

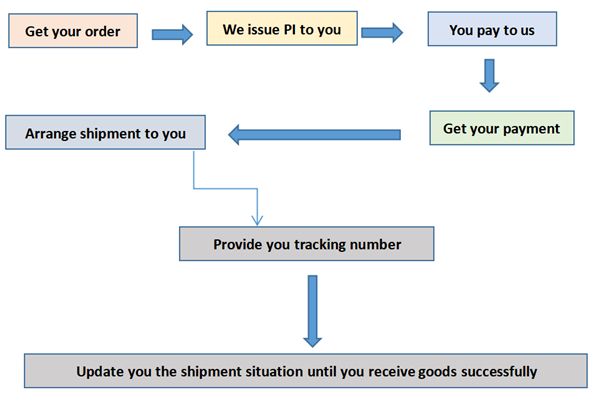

Order Steps

SHENZHEN CHAOYI MACHINE CO.,LTD

SHENZHEN CHAOYI MACHINE CO.,LTD